A. Specialty of Z30 Heavy duty Large Size H Beam Assembly Machine:

1. Purpose: This is a special made model of Large Size H Beam Assembly and Tack Welding Machine, for assembling and stitch welding on super large workpieces of T Beam/ H Beam/ I Beam;

2. Max. Workpiece Size: The max. height of assembled H Beam can be up to 3000mm, and flange thickness can be up to 80mm;

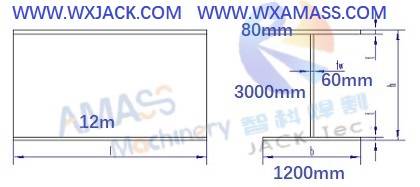

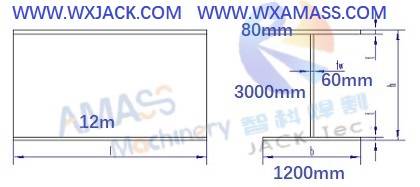

3. Illustration on Finished H Beam Assembled from H Beam Assembly Machine: (Fig.1)

Below are sketch indication on the largest size of workpiece, that can be produced from Wuxi JACK Z30 Large Size Steel Structure Beam Assembly Machine:

B. Application and Working Group of Z30 Heavy duty H Beam Assembly and Tack Welding Machine:

1. Working Group of Z30 Large Size H Beam Assembly Machine:

1) Feature: Z30 is the first set of core equipment deployed in Heavy duty H Beam Production Line; It is for assembling flanges and web into the formed WIP (Working In Process) of assembled and tack welded H Beam;

2) Photo View: Layout of H Beam Assembly Machine in Wuxi JACK H Beam Production Line: (Fig.2)

2. Related Equipment with Z30 Large Size H Beam Assembly Machine:

The 2 other critical equipment working together with the Z30 H Beam Assembly Machine are:

For completing on high current finished fillet welding in 45° orientation;

For correcting the flange deformation caused from SAW (Submerged arc welding) heat input.

C. Technical Specifications of Z30 Large Size Steel Structure Beam Assembly Machine:

1. Web Height Range: 300 ~ 3000mm

2. Web Thickness Range: 6 ~ 60mm

3. Flange Width Range: 200 ~ 1200mm

4. Flange Thickness Range: 6 ~ 80mm

5. Workpiece Length Range: 4000 ~ 12000mm

6. Assembling Speed: 4500mm/min, controlled with A.C. inverter, and displayed in operating panel

7. Spot Welding Mode: by manual (machine without CO2 welder)

8. Input Conveyor: 2600mm×3 (of which two segments are driving section)

9. Output Conveyor: 2600mm×3 (of which two segments are driving section)

10. Flange and Web Assembly Press: By means of hydraulic cylinder to assembly

11. H Beam Assembly Machine Power: 21 KW

12. Power Supply: 3P, AC 380V 50Hz

D. Working Style and Configuration of Z30 Large Size H Beam Assembly Machine:

1. 2 Main Functions of Z30 H Beam Assembly and Tack Welding Machine:

1) Fitting Up: Positioning and clamping 2 pieces of flange, with 1 piece of web, into formed H Beam;

2) Stitch Welding: Perform welding on the assembled workpiece at the same time, to strengthen it;

2. Assembling Form in Z30 Large Size H Beam Assembly Machine:

1) Semi Automatic: One side is driven with heavy force hydraulic oil cylinders, and the opposing side is managed with precise mechanical leadscrew, Shown in below:

2) Photo View: The integrated hydraulic and mechanical assembling design, in Wuxi JACK heavy duty H Beam Assembly Machine: (Fig.5)

3. Welding Mode and Style in H Beam Assembly Machine of the H Beam Production Line:

1) Manual: This is CO2 GMAW gas shielded welding, with cored flux welding wire, implemented by operator manual welding, shown in below:

2) Photo View: CO2 stitch welding in Wuxi JACK H Beam Assembly Machine: (Fig.6)

4. Operation on the Z30 Large Size H Beam Assembly Machine:

Correspondingly, there should be 2 operators for working on this Large Size H Beam Assembly Machine, fulfilling the 2 main duties of:

1) Managing on logic action for H Beam assembling, by means of buttons and switches on operating pendant;

2) Performing manual CO2 welding on the assembled workpiece, following it sending forward in assembling working speed.

E. Technical Features of Z30 Large Size H Beam Assembly Machine:

1. Assembling Principle in Z30 Large Size H Beam Assembly Machine:

To catering for assembling on such super large H Beam, we adopt the assembling style of:

1) One side positioning is managed with mechanical leadscrew;

2) The other side positioning is driven with hydraulic cylinders pushing;

3) Such working style is especially applicable for precise assembling large H Beam;

2. Composition of Assembling Unit in the Z30 Large Size H Beam Assembly Machine:

1) There are 2 sets of assembling rollers for both flange and web clamping;

2) Each set of the assembling roller is equipped with positioning leadscrew and hydraulic driving cylinders;

3) Even for assembling high thickness workpiece, this Large Size H Beam Assembly Machine can deliver clamping and assembling with great ease;

4) It is very suitable for assembling on heavy duty H Beam;

3. Gadgets for Assembling High H Beam in H Beam Production Line:

1) Gadget for Large H Beam: Considering the big height of workpiece vertical H Beam, there is workpiece supporting mechanism installed on mechanical gantry of the H Beam Assembly Machine, to prevent the high upright H Beam from tipping down. Please check below photo:

2) Photo View: The workpiece supporting mechanism in Wuxi JACK Z30 large H Beam Assembly Machine: (Fig.7)

3) This set of Large Size H Beam Assembly Machine does not have CO2 spot welding power supply. Its spot welding is implemented by manual labor. Welding consumables are prepared by customers.