1. Output of H Beam Assembly and Tack Welding Machine:

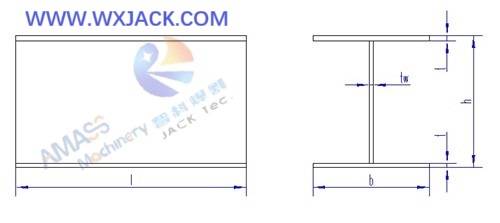

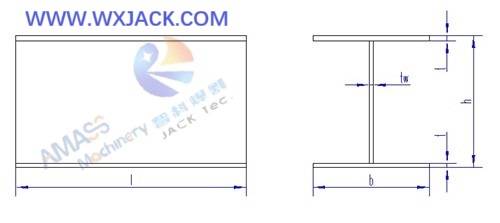

Semi-Finished H Beam: You can find the output working parts being produced from the H Beam Assembly Machine in the first photo: Fit up and spot welded H Beam. It is a kind of classical H Beam Production Equipment:

Produced H Beam from H Beam Assembly Machine: (Fig.1)

2. The Most Conspicuous Feature of High Precision I Beam Assembly Machine:

1) Function: For working of I Beam Assembly Machine, “high precision” is the foremost request on its performance:

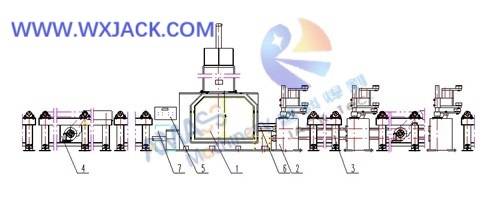

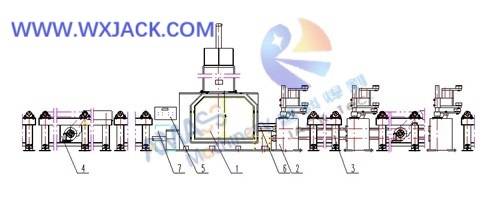

Layout of I Beam Assembly Machine at workshop: (Fig.2)

2) Task: The reason is, the essential task of this H Beam Production Equipment is to assemble the flanges and web into H structure and strengthen it with tack welding;

3) Related H Beam Production Equipment:

So, accurate fitting up in this H Beam Assembling Machine is the foundation for next step of:

a) H Beam Submerged Arc Welding Machine;

b) H Beam Flange Straightening Machine;

For the purpose of delivering qualified finish product of welding H Beam. Improper assembling operation in H Beam Assembly Machine will lead to unqualified finished H Beam.

3. How to Make a High Precision H Beam Assembly Machine:

To make accurate assembly and spot welding in the Z15~Z20 High Precision H Beam Assembling Machine, the exquisite design on mechanisms of this H Beam Production Equipment in every step of working is essential for success:

1) Rough Assembly through Hydraulic Pulling Rod Box in H Beam Assembly Machine:

a) Function: As introduced in product section of “Z20 Self Alignment H Beam Assembly Machine with Manual Tack Welding”, during in feeding of raw materials (Flange and web), this hydraulic drive manipulator pushes the raw materials into its proper position and clip them tightly:

Hydraulic pulling boxes along input conveyor of H Beam Assembly Machine: (Fig.3)

b) Working Principle: Two sets of the pulling rod system at both ends of input conveyor of the H Beam Assembly Machine makes the web and flange secured firmly and coming into shape of “T” or “H”, in the principle of “Two points make one line”;

c) Drive Source: The pulling rod system is acted with hydraulic cylinder and controlled with button, not manual job;

2) Precise Assembly Through Self Alignment Unit in I Beam Assembly Machine:

a) Importance: This is core unit for final assembly in the High Precision H Beam Assembly and Tack Welding Machine:

Precise fitting up and tack welding mechanism in H Beam Assembly Machine: (Fig.4)

b) Structure: In one set of H Beam Assembly Machine, there are eight pieces of rollers for web self alignment at its top, and four pieces of rollers for flange self alignment at its bottom;

c) Control Unit: The actions of these alignment rollers are controlled with PLC of the H Beam Assembly Machine without human intervention, making pinpoint assembly of web and flange;

3) Fine Tuning with Eccentric Rollers of Self Alignment Unit in H Beam Assembly Machine:

a) Precision Assurance: To be capable of further managing on precise assembly to its extreme best degree, in this H Beam Production Equipment of High Precision H Beam Assembly Machine, all the alignment rollers for web and flange alignment are all eccentric type;

b) Eccentric Rollers: The above mentioned eight plus four pieces, the eccentric rollers marked in red color square are for performing web alignment of the I Beam Assembly Machine, and marked in yellow color are for flange alignment:

Eccentric rollers in precise fitting unit of I Beam Assembly Machine: (Fig.5)

b) Through Slot: As can be observed from the above photo, there is a through slot in the surface of each piece of alignment roller;

c) Fine Tuning for H Beam Assembly: With a proper tool (such as bolt driver), the alignment rollers can have another 2mm adjustable horizontal stroke to acquire the best precise degree of final assembly. This design makes the equipment a truly High Precision I Beam Assembly Machine;

4) Web and Flange Terminal Alignment in the H Beam Assembly Machine:

Another measure taken to guarantee exact assembly in this H Beam Production Equipment is web and flange terminal alignment unit:

Web and flange alignment in H Beam Assembly Machine: (Fig.6)

a) Hidden Risk: Imagine the web and flange are sent into the I Beam Assembly Machine and laid on its conveyor for assembling. And suppose terminals of web and flange are not aligned … It is an easy happen issue, because web and flange are two pieces of individual parts;

b) Action on Web and Flange Alignment: A terminal alignment unit is used here for solving this issue in the H Beam Assembling Machine. At the time web and flange are sent to its proper place in the H Beam Assembly Machine, a cylinder drive fender will erect (Marked in yellow square in above picture), stopping terminals of web and flange, and making them in alignment. This mechanism makes another contribution to the High Precision H Beam Assembly Machine;

c) Operation: This unit is operated with corresponding toggle switch on operating pendant of the H Beam Production Equipment:

Operating panel of H Beam Assembly Machine: (Fig.7)

4. Technical Parameters of Z15~Z20 High Precision H Beam Assembly Machine:

Below are specifications of the Z15~Z20 High Precision I Beam Assembly Machine (H Beam Assembling Machine):

Model | Z15~Z20 Self Alignment High Precision H Beam Assembly and Tack Welding Machine |

I Beam Web Height | 200 ~ 1500/1800/2000 mm |

Fitting I Beam Web Thickness Range | 6∽32 mm |

Fitting I Beam Flange Width Range | 200∽800 mm |

Fitting I Beam Flange Thickness Range | 6∽40 mm |

Fitting I Beam Length Range | 4000∽12000 mm |

Max. I Beam Weight | 20 Ton. |

Main Driving Motor | 5.5 kW |

Working Mode | Manual/Single/Auto |

Web and Flange Alignment Style | Self Alignment (Automatic Fitting Up) |

Tack Welding Style | Automatic CO2 tack welding |

CO2 Gas Shielded Welding Power Source | Panasonic KR350 or HUAYUAN NB350 |

Operator | 1 operator |

Assembly and Tack Welding speed | 500 ~ 6000 mm/min. |