A. Purpose of the SXBJ-12 Large Size Metal Plate Edge Milling Machine:

1) This large size machine is used for metal plates edge processing after thermal cutting and preparing the edges for welding;

2) It allows to process, depending on mill type and shape, V type edge milling, X type edge milling and U type edge milling.

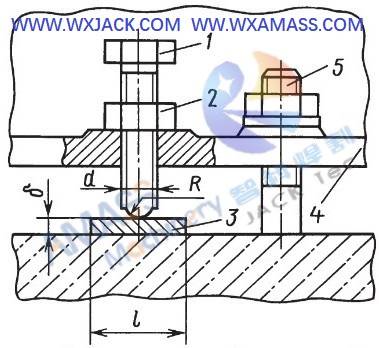

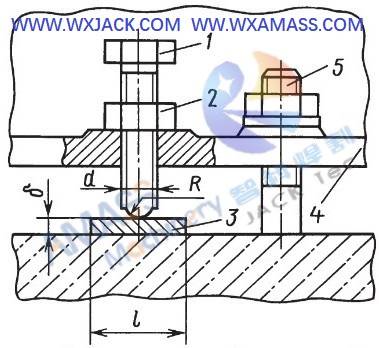

3) The edge processing and its finished steel plate in Wuxi JACK SXBJ-12 machine: (Fig.1)

B. Construction Description, Technical Requirements and Working Principal of SXBJ-12 Large Size Steel Plate Edge Milling Machine Main Body:

1. Main Construction of the SXBJ-12 Large Size Sheet Metal Edge Milling Machine:

1) Machine bed of the Sheet Metal Edge Milling Machine is of welding structure, which is destressed through high temperature temper;

2) Linear guides, gear rack and guide rail are placed on the mechanical bed of the machine;

3) On the bottom surface of upper gantry beam, hydraulic jacks are installed, for pressing the workpiece firmly;

4) The array of hydraulic drive jacks pressing the steel plates firmly in the Wuxi JACK Large Size Edge Milling Machine: (Fig.2)

2. Installation and Levelness of Worktable in SXBJ-12 Large Size Steel Plate Edge Milling Machine:

1) For pulling the workpiece out from processing zone of the Edge Milling Machine, shall make the indentations for freely moving of the hydraulic push devices through it;

2) Wherein, indentations shall not be placed directly under workpiece clamping hydraulic jacks;

3) For stable fixation of the mechanical bed of the machine on a foundation, and to avoid deformation (deflection) of working table surface, installation and height adjustment shall be made with use of release forced adjusting bolts according to the scheme, similar to showed in sketch:

4) Design sketch on Adjusting Bolts for installing and height modulation of worktable in the Metal Plate Edge Milling Machine: (Fig.3)

3. Milling Head 3 Axis Movement in the SXBJ-12 Large Size Metal Plate Edge Milling Machine:

1) Milling head should have ability to install mill with conic shank end. The delivery set of the large size machine should include the pull stud for mill fixing;

2) For milling column secured locking after Z Axis adjustment, manual clamp with handwheel is used.

3) Rotation of milling head for adjusting milling angle in this double heads Edge Milling Machine is motorized type, with motor reducer and encoder.

C. Main Components List and Technical Features of SXBJ-12 Large Size Sheet Metal Edge Milling Machine:

1. Milling Head: 2 pieces of Taiwan produced E-LONG MU-6S, 11kW high power;

2. Mill Cutter: GMA250 of different diameters and materials, for edge milling on diversified dimensions and materials of workpieces in the machine;

3. Linear Guiderails for Guiding of Milling Head along 3 Axis in SXBJ-12 Large Size Metal Plate Edge Milling Machine:

1) The upper rails of X Axis along 12m Stroke of work table:

HIWIN guide CG45, sliding block CG4CGH45HAZAC, made in Taiwan;

2) The Lower rails of X Axis along 12m Stroke of the machine:

Carbon steel #45, Tempered, surface hardness HRC48-52;

The upper and lower rails for milling head X axis movement in the machine: (Fig.4)

3) The Y Axis for Guides of Vertical Movement in the machine:

Carbon steel #45, Tempered, surface hardness HRC48-52;

4) The X Axis for Feeding Forward and Backward Movement in the machine:

Carbon steel #45, Tempered, surface hardness HRC48-52;

4. Hydraulic and Electric Control Elements in the SXBJ-12 Large Size Steel Plate Edge Milling Machine:

1) Electric Inverters for milling speed control: Japan brand Mitsubishi;

2) Hydraulic components: Chinese produced YOSHYD;

3) Electric Motor for Driving Milling Head along X Axis: Taiwan produced CPG, CV50-2200W-100S;

4) Electric Motor for Driving Milling Head along Y Axis: China produced Jiaoxing, JMRV90-40-1.1KW;

5) Electric Components of the SXBJ-12 Large Size Advanced Confinguration Metal Plate Edge Milling Machine: China produced Siemens, FIF, DELIXI;

6) Milling Head Movement in X Axis Digital Indication Units: China produced UP5135;

7) Milling Heads Rotation Control Panel in the machine: China produced OP320-A;

8) Down Guide Rail Dust Protection for Milling Operation in the large size machine: 2 stage dust scraping unit;

9) Lubrication System for Guides: Manual lubrication system;

10) Hydraulic Feeding System of the machine: 2 feeding speeds – fast and slow;

11) Mill Cutter Cover for Milling Head in the machine: Metal protective cover;

12) Working Zone Lighting: Local lighting on each milling head;

13) Safety Icons along the Whole Area of the Large Size Machine: Striking safety icon conforms to international standard;

14) Electric Cabinet of Milling Unit: Independent for each unit, with vibration dampers, installed on the moving platform of the machine;

15) Operator Panels of the SXBJ-12 model machine: In Russian language captions. Please check the attached photo and below:

The Russian language interface in HMI (Human machine interface) of the SXBJ-12 Edge Milling Machine: (Fig.5)

D. Technical Parameters of SXBJ-12 Large Size Steel Plate Edge Milling Machine:

SXBJ-12 Large Size Sheet Metal Edge Milling Machine |

Plate Thickness Processing Range | 6–50 mm |

Plate Maximum Processing Zone Length | 12000 mm |

Plate Maximum Processing Width | 2500 mm |

Plate Maximum Weight | 40 Tons |

Edge Milling Accuracy | Bevel Processing Accuracy | ± 1° |

Milling Head | Model | ELONG MU-6S (Taiwan) |

Quantity of Milling Units | 2 |

Milling Head Power | 11 kW |

Spindle Rotation Speed | 75/115/165/240/345/505 (6 steps) rpm |

Permissible Miller Diameter | 125–250 mm |

Milling Head Turning | Rotation Motor Power | 0.4×2 kW |

Milling Head Rotation Angle | Milling unit No. 1 | -45°... +45° |

Milling unit No. 2 | 0°... +90° |

X Axis Movement | Type | gear rack and pinion |

Working Speed, | 0.15-1 (Stepless, with inverter) m/min |

Idle Speed | 4 m/min |

Carriage Moving Motor Power | 2.2×2 kW |

Y Axis Movement | Type | Screw and nut gear |

Milling Head lifting motor power | 1.1×2 kW |

Z Axis Movement | Type | Manual, through reducer |

Milling head Z Axis feeding rate | 0.8 mm/rev. |

Milling head feeding within Z Axis | 250 mm |

Machine Total Power | ~35 kW |

Hydraulic Clamping Jacks | 18 pcs |

Distance between Hydraulic Clamping Jacks | 650 mm |

Alignment Fender Units | 6 pcs |

Working Zone Lighting | Local lighting on each milling head |

Machine Total Weight | Overall Weight | ~25 Tons |