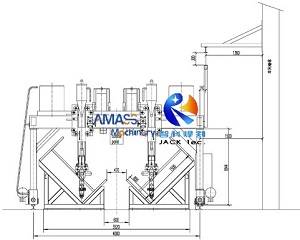

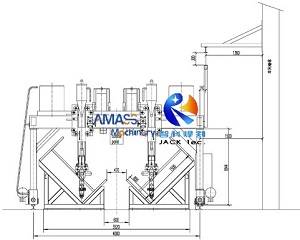

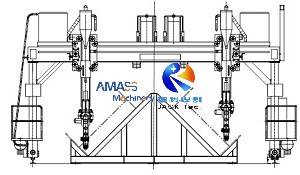

LHA series Gantry H Beam SAW Equipment can be seen everywhere across all facilities of steel structure industry, delivering superior quality welding H Beam of sizes: (Fig.1)

1. SAW Put into Use in LHA H Beam Gantry Welding Machine:

1) For all the heavy duty H Beam submerged arc welding machine, including LHA/ LHC/ LHT models, since its main duty is to finish SAW on the workpiece, the proper selection on specific welding mode, and model of SAW welding power source, as well as control console accordingly, is very important;

2) In the product section of “45° Fillet Welding LHA Series H Beam Gantry Welding Machine” and “LHC Column type High Quality H Beam Submerged Arc Welding Machine”, we recommend two brands of SAW power source: The Chinese HUAYUAN and U.S. Lincoln.

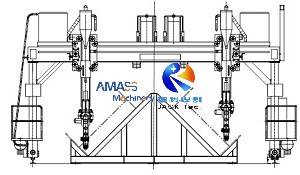

2. Model Selection and Combination in LHA Gantry I Beam Welding Machine:

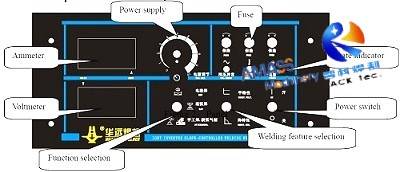

Going further, there are several models of these SAW power supply to be selected for being applied in Gantry H Beam Submerged Arc Welding Machine: (Fig.2)

1) ZD7-1000(HUAYUAN) or DC-1000(Lincoln) for I Beam Welding Machine:

a) This refers to D.C. current of max. 1000A for SAW welding. It can meet the requirement of most majority SAW;

b) For all the large size Gantry H Beam SAW Machine produced by our company (H Beam, LHT and LHC H Beam SAW Machine also), under the Single Arc submerged arc welding mode, we use this model of either of the two brands;

2) MZE-1250(HUAYUAN) or AC-1250(Lincoln) for H Beam SAW Equipment:

a) This refers to A.C. current of max. 1250A. It is seldom used as sole SAW power source for our automatic Gantry I Beam Welding Machine (H Beam, and LHT& LHC H Beam SAW Machine also);

b) Instead, under Tandem Arc SAW mode, it works together with DC-1000 (or ZD7-1000) SAW power supply. Which means, one set of DC-1000 and AC-1250 each for Lincoln, or one set of ZD7-1600 and MZE-1250 each for HUAYUAN, to be used in combination in I Beam Welding Machine;

3) ZD7-1250(HUAYUAN) or DC-1500(Lincoln) for H Beam Gantry Welding Machine:

This refers to D.C. current of max. 1250A for HUANYUAN, and 1500A for Lincoln. Both the models have too large current, which is not applicable for working as SAW power source of our heavy duty H Beam Gantry Welding Machine.

3. Difference between D.C. and A.C. SAW Power Source in Gantry H Beam SAW Equipment:

1) D.C. power source features in delivering welding seam of deeper crater and deposition;

2) A.C. power source features in delivering welding seam of wider weld fusion and comparative good appearance;

3) For our heavy duty LHA H Beam Gantry Welding Machine (LHT and LHC I Beam Welding Machine also), the SAW power source is one set of Lincoln DC1000 (or HUAYUAN ZD7-1000) for Single Arc, and, as mentioned in the previous segment, one set of Lincoln DC1000 together with one set of Lincoln AC1250 (or one set of HUAYUAN ZD7-1600 together with MZE 1250 each) for Tandem Arc.

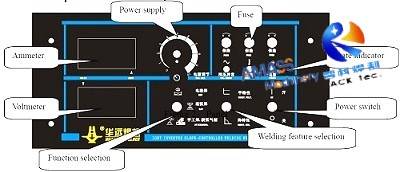

4. Model of Welding Power Source Consoles in LHA H Beam Gantry Welding Machine:

1) For HUAYUAN brand power source, there is no independent model for the console. It shares the same model with the power source: (Fig.3)

2) For Lincoln brand power source, the mating console used in series of H Beam SAW Welding Machine is:

a) NA-3 for DC1000 model SAW power supply;

b) NA-4 for AC1250 model SAW power supply;

c) NA-5 is the version of state-of-art digital control (welding parameters pre-set and display);

d) Lincoln Wire feeder also has the model of NA-3. Need to take care no confusion between console and wire feeder;

3) For general introduction on LHA gantry I Beam Welding Machine, please check product section of “LHA Gantry type H Beam Submerged Arc Welding Machine”.

5. Technical Parameters of LHA H Beam Gantry Welding Machine:

Below are specifications of this LHA High Precision Gantry I Beam Welding Machine (Gantry H Beam SAW Equipment):

LHA Gantry H Beam SAW Welding Machine (Gantry H Beam Submerged Arc Welding Machine) |

Parameter | Specification | Note |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 1200/1500/1800/2000 | Varies on models |

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Submerged Arc Welding type | 45° fillet welding |

|

Submerged Arc Welding mode | Single Arc, Or Tandem Arc |

|

Welding Power Source brand | Chinese HUAYUAN or U.S.A Lincoln | ZD7-1000(ZD7-1600 for Tandem Arc) or DC-1000 (A.C.: AC1250 or MZE 1250) |

Welding Power Source quantity | 2 sets in the case of Single Arc, And 4 sets in the case of Tandem Arc | Machine quotation is different as in the case of Single Arc and Tandem Arc |

Console of welding power source | NA-3 for Lincoln ZD-7 for HUAYUAN |

|