A. Function of SXBJ-6 Double Heads Groove Making Sheet Metal Edge Milling Machine:

1. Usage: This machine is for machining on welding grooves on edges of sheet metal, into various designated forms and angles;

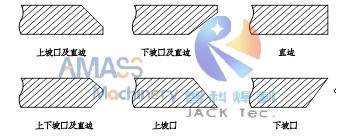

The sketch on common seen grooves available for being machined in SXBJ model Edge Beveling Machine: (Fig.1)

2. Milling Angle in the SXBJ-6 Groove Making Plate Beveling Machine:

1) One piece of its milling head has milling angle of 0° ~ 90° for doing upper edge grooving, which implicates from straight edge to flat edge milling:

a) The 0° straight edge milling in Wuxi JACK machine: (Fig.2)

b) The 89° flat edge milling in Wuxi JACK Groove Making Plate Edge Milling Machine: (Fig.3)

2) The second piece of milling head has milling angle of -45° ~ 0° for doing lower edge milling:

The -45° slant edge milling in Wuxi JACK SXBJ-125: (Fig.4)

3. Workpieces Applicable for SXBJ-6 Groove Making Plate Edge Milling Machine:

1) The sheet metal materials that can be edge milled cover: Carbon steel, Alloy steel, Stainless steel. The corresponding facer blade should be made of different material;

2) The max. specifications of carbon steel for this model machine are: Thickness 50mm, length 6000mm, and width 2200mm. Accordingly, the max. weight is around 5.5 Ton.

B. Structure and Technical Specialties of SXBJ-6 Groove Making Plate End Milling Machine:

1. Mechanic Frame of the SXBJ-6 Plate Edge Beveling Machine:

1) Mechanical main body of the Edge Milling Machine is assembled into shape from two sections: The upper section pressing beam, and the lower section of working table and base bed;

2) The main mechanical bed of machine is of welding structure, which is annealed thru high temperature tempering. So, it has good features of stable size, little deformation and smooth work;

3) Mechanical main frame of the Wuxi JACK SXBJ-6 model machine: (Fig.5)

2. Movement of Milling Head in Work Table of SXBJ-6 Groove Making Plate Beveling Machine:

1) Each piece of the milling is installed on a set of motor drive moving carriage, which is installed on the mechanical base bed of the double heads Edge Milling Machine;

2) The cross section of the moving carriage is in the shape of internal hollow trapezoidal, with driving motor assumed inside;

3) The movement of the moving carriage during running of this machine is guided with 2 pieces of linear guiderail, and transmitted with rack;

4) The 2 pieces of moving carriage fit on the mechanical base bed of machine: (Fig.6)

3. Milling Head of the SXBJ-6 Groove Making Edge Milling Machine:

1) The 2 pieces of 7.5kW milling head are produced by Chinese mainland professional supplier;

2) Its spindle revolution has 6 optional choices, which is adjusted by means of manual turning lever;

3) With different facer material, various material like carbon steel, alloy steel, stainless steel can be beveled in the 6m stroke conventional size Edge Milling Machine;

4) We install one piece of 200mm and one piece of 250mm diameter standard facer unit;

5) The 7.5kW milling head equipped with the SXBJ-6 Plate Edge Milling Machine: (Fig.7)

4. Working Action of Milling Head in the SXBJ-6 Sheet Metal Edge Milling Machine:

Each piece of the milling head has 4 degrees of freedom during edge milling operation:

1) Up and down, under motor drive;

2) Movement along lengthwise of steel plate, or worktable of machine, under motor drive;

3) Forward and backward for adjusting on feeding stroke and milling cut depth, under manual worm gear, controlled with counter, to have precise management;

4) Swing for milling angle management;

The manual worm gear and counter for controlling feeding forward of milling head in the Plate Edge Milling Machine: (Fig.8)

5. Assistant Function Units in SXBJ-6 Groove Making Sheet Metal Edge Milling Machine:

1) Fitting position and lubricating way: Manual lubricating pump is fit on the milling unit: Around 10 droplets of lubricating oil are dropped onto top and bottom rails in the period of 1 minute, ensuring constant lubricating film on the surface of the rails;

2) Advantage: Also because of little oil volume consumed during running period, working floor of the Plate Edge Milling Machine will not be contaminated;

3) At the feeding side of machine, there is 1 set of feeding rack. Rollers are installed on the rack, which help to feed the workpiece to its pressing position easily.

C. Technical Parameters of SXBJ-6 Groove Making Sheet Metal Edge Milling Machine:

No. | Parameter | Value | Note |

1 | Max. length of plate machined one pass | 6000 mm |

|

2 | Plate Thickness | 6-50 mm |

|

3 | Distance from pack to worktable | 100mm |

|

4 | Milling Angle | Top milling unit | 0° to +85° | Angle adjust by manual |

Under milling unit | 0° to -45° |

5 | Model of milling head | HT750 | Made in China by professional supplier |

6 | Power and rpm of milling head | 7.5kW、1440r/min |

|

7 | Diameter of facer plate | D=Ø125-Ø250mm | Ø200 Facer unit by default |

8 | Spindle rpm | 75-420 r/min | 6-grades adjust by handwheel |

9 | Edge Milling Speed | 150 -1,000 mm/min. | VFD |

10 | Milling motor power | 2.2kW | Inverter motor |

11 | Idle speed | Vf=4m/min |

|

12 | Hydraulic motor power | 5.5 kW |

|

13 | Hydraulic press Jack | 11 sets | Distance is 600mm |

14 | Workpiece support racket | 1 set | Total 7 pieces |

15 | Workpiece support racket length | 1100 mm | As the plate width |

16 | Power of supply | 380V, 50Hz, 3 Phase |

|