A. Function, Strong Points and Application of Wuxi JACK J Series Reinforced Angle Stiffener Plate Straightening Machine:

1. Applicable Background of Angle Ribbed Plate Straightening Machine:

1) In Shipbuilding/ Bridge/ Port Machinery industries, ribbed plates are often used to strengthen mechanical body of finished construction;

2) These ribbed plates are fabricated from several pieces (Usually 3~6 pieces) of Angle Steels onto a piece of large carbon steel plate;

3) After being fabricated, Angle Steels on stiffening plates easily bulge up, making surface of the entire plate unit uneven;

2. Function of Angle Rib Plate Straightening Machine:

1) Wuxi JACK developed J models Angle Stiffener Plate Straightening Machine is for levelling the above-mentioned upturned Angle Steels on plate units:

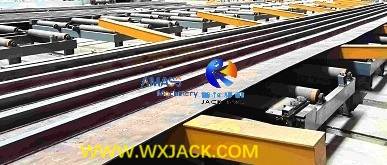

2) A piece of 30 meter long 3 meter width reinforced plates unit being flatten from Wuxi JACK J16 Reinforced Angle Rib Plate Straightening Machine at customer workshop: (Fig.1)

3. Advantages of Wuxi JACK Angle Stiffening Plate Straightening Machine:

1) Highly Automation: The entire operation can be managed with easy job. Except workpieces loading in and out, all the remaining jobs are processed automatically, including straightening ram displacement control;

2) Precise Position of Straightening Rollers in Angle Ribbed Plate Straightening Machine:

a) Position of fabricated Angle Steels onto plate differs, within certain variation range of 450~ 600mm;

b) Correspondingly, during running of the Angle Stiffening Plate Straightening Machine, straightening units need to be moved laterally, to aim on the Angle Steels precisely;

c) Such horizontal movement displacement is managed with closed loop control, and detected with encoders;

3) Intuitive Working Process: Operator just need to key in control parameters at initiation of work period:

Advanced technology HMI (Human machine interface) monitor in Angle Ribbed Plate Straightening Machine: (Fig.2)

4. Related Equipment with Reinforced Angle Stiffener Plate Straightening Machine:

1) ASM Series Angle Steel Straightening Machine: For straightening longitudinal deflection on single piece of Angle Steel;

2) RH Series Edge Rounding Machine: For deburring and removing sharp angles on edges of ribbed plate unit.

B. Applicable Workpieces for J16 Reinforced Angle Rib Plate Straightening Machine:

1. Number of Angle Steels on Workpieces of Angle Stiffener Plate Straightening Machine:

1) It can be from 1 piece to several pieces, such as 5 pieces:

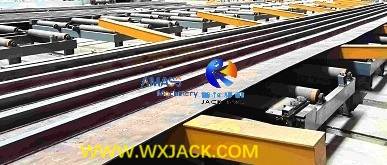

2) A piece of 5 Angle Stiffener Plate levelled from Wuxi JACK J16 Angle Ribbed Plate Straightening Machine: (Fig.3)

3) Meanwhile, there are 3 sets of straightening units in Angle Rib Plate Straightening Machine. So, the straightening units need to be adjusted on its lateral positions several times, to finish the leveling task;

2. Width of Reinforced Plate Unit in Angle Stiffening Plate Straightening Machine:

1) Min. width request on the reinforced plate unit is 800mm;

2) Max. width of reinforced plate that can be fit into working zone of the Stiffener Plate Straightening Machine is 3000mm;

3. Thickness Range of Stiffening Plate Unit: From 6mm to 16mm. This is model “J16” got from;

4. Length Range of Stiffener Plate Unit: There is no restriction on the shortest and longest size. So long as it can be laid onto input and output conveyors of the Rib Plate Straightening Machine;

5. Intervals of Angle Steel on the Ribbed Plate Unit: As mentioned previously, this adjustable interval of fabricated Angle Steels on the reinforced plate unit is from 450mm to 600mm;

6. Material of Rib Plate Unit: Most majority conditions, customer apply carbon steel ribbed plate unit. Of course, it can be any other available sheet metal, such as 16Mn/ Stainless Steel/ Alloy..., etc.

C. Operation on J16 Reinforced Angle Stiffening Plate Straightening Machine:

All the main actions of the Angle Stiffener Plate Straightening Machine are controlled with advanced technique software and hardware integrated operating system in HMI station:

1. Primary Interface in J16 Angle Stiffener Plate Straightening Machine: (Fig.4)

1) All the main working motions of the machine are managed in this interface;

2) Such as: POWER ON/ OFF; Oil Pump Start ON/ OFF; Power Indicating Lamp; Straightening Units 1~3 Start ON/ OFF, etc.

2. Straightening Unit Interface in J16 Angle Rib Plate Straightening Machine: (Fig.5)

1) In this interface page, lateral movement and position of each straightening unit is controlled;

2) Operator just need to key in corresponding process control parameters;

3. Hydraulic Station Interface in Angle Ribbed Plate Straightening Machine: (Fig.6)

Purpose: Hydraulic system gives heavy force and reliable power on straightening process:

D. Structure and Main Units of J16 Reinforced Angle Ribbed Plate Straightening Machine:

1. Constructure of J16 Angle Rib Plate Straightening Machine:

1) Running Site: This custom design Stiffener Plate Straightening Machine is deployed in large scale Shipbuilding production line;

2) It has a set of strong base fixed installed mechanical main frame, with input and output conveyors;

3) During operation, workpieces move through the entire working zone of the Stiffening Plate Straightening Machine, and being levelled simultaneously;

4) Operating site of Wuxi JACK J16 Angle Stiffening Plate Straightening Machine: (Fig.7)

2. Main Units in J16 Angle Stiffening Plate Straightening Machine:

1) Mechanical base bed, with grounding style workpiece holding platform;

2) Primary driving motor reducer;

3) 4 pieces of round cross upright columns;

4) Overhead platform, for laying on control board and hydraulic pump station of the Rib Plate Straightening Machine;

5) 3 sets of top and bottom installed coupled straightening unit;

6) Input and output conveyors, its length can be designated by customer;

7) Electric control and operating system;

8) Hydraulic drive system and station.

Main frame central unit of Wuxi JACK J16 Reinforced Angle Rib Plate Straightening Machine at customer factory: (Fig.8)

E. Technical Features of J16 Reinforced Angle Stiffener Plate Straightening Machine:

1. 3 Sets of Straightening Units in the Angle Rib Plate Straightening Machine:

1) Working Mode: The 3 sets of straightening units can either work as a team, or individually;

2) Its horizontal movement is driven with motor reducer, detected with encoder, protected with electric limit switches and mechanical hard stops;

3) The critical action of downward stroke straightening is powered with hydraulic oil cylinders, and operated with 2 stages of fast down and inching adjustment, in the Angle Stiffening Plate Straightening Machine;

4) Each set of straightening unit has 1 piece of top and bottom assembled straightening roller, always move in phase, and have co-linear central axis;

5) 3 sets of straightening units in Angle Ribbed Plate Straightening Machine: (Fig.9)

2. Holding and Transporting Workpieces into and Through Angle Ribbed Plate Straightening Machine:

1) Quantity: There are 1 piece of supporting roller installed at front and rear side of mechanical main frame respectively, for holding on and guiding workpieces moving forward through the Stiffener Plate Straightening Machine;

2) Drive: These 2 supporting rollers are hydraulic drive, with 40mm elevating stroke. The 2 rollers can be elevated separately;

3) Transmission: The 2 supporting rollers are integrated with bottom straightening roller by means of chain sprocket coupler;

4) Vertical Positions: Its bottom position can be 20mm lower than conveyors of the Rib Plate Straightening Machine; Top position 20mm higher than that of conveyors;

View on the 2 pieces of supporting rollers in Wuxi JACK customer installed J16 Reinforced Angle Stiffener Plate Straightening Machine: (Fig.10)

F. Technical Parameters of J16 Reinforced Angle Rib Plate Straightening Machine:

No. | Parameters | Specification | Note |

1 | Suitable Ribbed Plate Width | 800-3000 mm |

|

2 | Suitable Ribbed Plate Thickness | 6-16 mm |

|

3 | Angle Steels Intervals | 450-600 mm |

|

4 | Straightening Velocity | 6000 mm/min |

|

5 | Angle Steel Specification | 80-120 mm | Side Length |

6 | Min. Interval of Angle Steels Straightened simultaneously | 680 mm | When less than 680mm, straightening should be performed 2 times |

7 | Height of Input and Output Conveyors Rollers | 600 mm |

|

8 | Elevating Stroke of Front and Rear Supporting Rollers | 40 mm |

|

9 | Straightening Units Quantity | 3 Sets | Each unit includes 1 piece of top and bottom roller each |

10 | Lateral Movement of Straightening Rollers | Zero position set with proximity switch | Displacement detected with encoder |

11 | Rated Hydraulic Pressure | 25 MPa |

|

12 | Straightening Oil Cylinder Model | D125/d70-S200 |

|

13 | Primary Drive Motor Power of Reinforced Angle Stiffener Plate Straightening Machine | 15 kW |

|

14 | Hydraulic Pump Station Power | 5.5 kW |

|

15 | Electricity Power | AC380V/ 50Hz/ 3P |

|