A. Function, Special and Strong Points of CNC-DX0815 Steel Structure CNC End Face Milling Machine:

1. Task of CNC-DX0815 Metal Structure CNC End Face Milling Machine:

1) Nature: This is a set of special design and produced compact size machine, which will be used at a Russian customer site, for milling on end faces of various steel structure workpieces;

2) The largest volume of workpieces for this tailor made CNC End Face Milling Machine is flange, in the size of 940mm width/ 520mm height/ 60mm thickness, which should be milled on its 940mm x 520mm surface;

3) The special point for end face milling operation here is fixture of the upright orientated flange during face milling operation, which, with only 60mm thickness, should be gripped firmly on this narrow rim into the CNC Steel Structure Flange Milling Machine, and should not be spoiled on this rim from clamping;

4) Below is photos illustration on challenge we face for designing. Videos taken during trial run at Wuxi JACK workshop please check attached video and more at our YouTube channel:

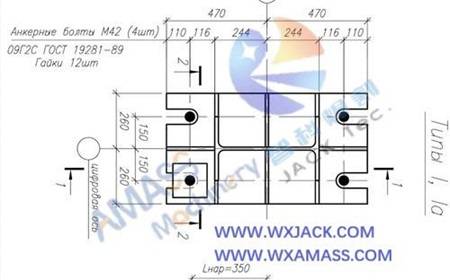

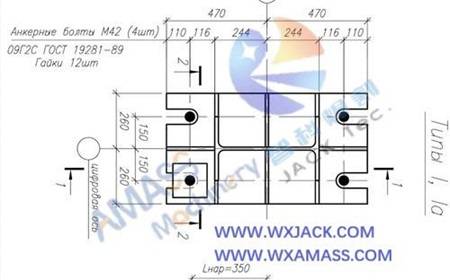

a) Front view on flange dimension and outline from customer to be milled: (Fig.1)

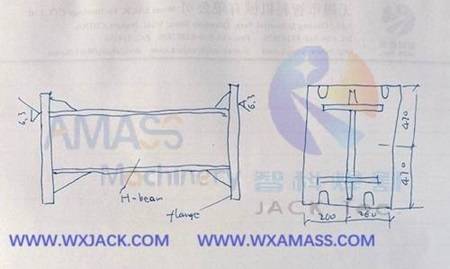

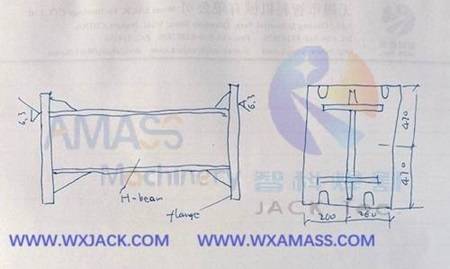

b) After end face milling operation, the workpiece flanges will be welded onto both ends of H Beam: (Fig.2)

c) Validating on design of fixture to meet customer expectation, during facility commissioning on CNC-DX0815 at Wuxi JACK: (Fig.3)

2. Advantages of CNC-DX0815 H Beam CNC End Face Milling Machine:

1) Easy and Relieved Operation: With CNC controller as its central controlling unit, this machine can help operator relieving from mental calculation and arduous trace during milling operation, and focus on monitoring on end face milling operation. In other words, operator can take a brief break during running period;

2) Just compare operator status at working sites of conventional H Beam End Face Milling Machine with regard to CNC Steel Structure End Face Milling Machine:

a) Operator of Wuxi JACK CNC-DX3030: Stand by and watch on: (Fig.4)

b) Operator of Wuxi JACK DX1520 Pipe Steel Structure End Face Milling Machine: Hard on manipulating milling head for special trace milling operation: (Fig.5)

3) All the types of special outline cross section workpieces can be end faced with high precision and efficiency, with CNC End Face Milling Machine: (Fig.6)

B. Technical Features of CNC-DX0815 CNC Steel Structure Flange Milling Machine:

1. Origin: This special design machine is upgrade from DX0815 Steel Structure Flange Milling Machine. Which, after the 1st time remote acceptance at Wuxi JACK facility, the Russian customer thought CNC control had better be introduced to the machine, so that their operator can “Take a break and drink a cup tea” during milling operation;

2. What Wuxi JACK Team Do to Upgrade the DX0815 into CNC-DX0815 CNC Flange Milling Machine:

1) Electric Control: This is the core step in renovating the conventional control machine. The original 2 pieces of A.C. inverters and potentiometers were replaced with CNC control system;

2) Milling Head Drive: The original 2.2kW/ 3kW Y series A.C. motor for driving the 7.5kW milling head moving in working speed along vertical and horizontal direction (Y/ X axis) were replaced with 1.5kW/ 2kW servo motors;

a) The X/ Y axis servo driver for servo motors being installed inside control board of CNC-DX0815: (Fig.7)

b) The 7.5kW milling head in Wuxi JACK DX series H Beam End Face Milling Machine: (Fig.8)

3) Operating Panel: The original hanging pendant was removed, and CNC monitor takes on the job:

a) The original operating pendant in DX0815 Flange Milling Machine: (Fig.9)

b) The CNC controller in upgraded Wuxi JACK CNC-DX0815 CNC End Face Milling Machine: (Fig.10)

3. Technical Index of CNC-DX0815 CNC H Beam End Face Milling Machine:

1) Electric Control: High precision closed loop control, with negative feedback on milling head trace and position during milling operation detected with encoder, and displayed on monitor screen of CNC in real time;

2) Servo Motor Drive: Servo motors have capability of output higher torque than conventional A.C. motor, delivering more stable milling head movement;

3) Position Control and Detection Precision can be up to .xxx level;

4) CNC and Electric Control System Protection against harsh and slag spray working site of the machine exceeds IP54 level, guaranteeing long term service life of the machine.

C. Operating On CNC-DX0815 CNC Steel Structure End Face Milling Machine:

1. Clamping Work Parts into Fixture of CNC End Face Milling Machine:

a) For special upright orientated flange, just hold it into the dedicated use fixture of machine: (Fig.11)

b) For “standard” workpieces H/ BOX Beam, just clamp it into standard hydraulic drive workpiece fixing table: (Fig.12)

2. Managing On Milling Program in Steel Structure CNC End Face Milling Machine:

1) Original Workpiece Data Input: Just key in data on overall dimension for regular (BOX/ H/ I/ Cross) beams, and .dwg file or other editable file for special working parts, by way of its interface port;

2) The next step operation and monitor can be fulfilled with soft functions keys on screen of CNC controller: (Fig.13)

3. Finally, this is overall appearance of Wuxi JACK CNC-DX0815 CNC H Beam End Face Milling Machine (Hydraulic pump station not in the photo): (Fig.14)

D. Technical Parameters of CNC-DX0815 Metal Structure CNC H Beam End Face Milling Machine:

No. | Parameter | CNC-DX0815 CNC Steel Structure Flange Milling Machine |

1 | Suitable Workpiece Max. Cross Section Size Height × Width= | 800 × 1500 mm |

2 | Suitable Section Shape of Workpiece | Round/Curve/ H / I /Cross / BOX / Triangle/ ... All |

3 | X / Y axis Workpiece Width End Face Milling Speed | 100~ 800 mm/min | Working speed, controlled and displayed with CNC system |

4 | Column and Face Milling Carriage Idle speed in X/ Y axis | 1400 mm/min | Constant speed |

5 | CNC Control System | Shanghai FANGLING F series |

6 | X/ Y axis Workpiece Width/ Height End Milling Head Movement Guide | Heavy duty Precise Linear guiderail, assembled onto Machine base bed and upright column |

7 | X / Y axis Workpiece Width/ Height Milling Head Servo Drive Motor | 2.0 kW / 1.5 kW | Panasonic Servo A6 series |

8 | Milling Head Power | 7.5 kW | Made by Professional Supplier |

9 | Milling Head Spindle Revolution | 100 ~630 rpm | 6 grades Revolution adjustable with lever |

10 | Diameter of Face Milling Cutter | Ø160 ~320 mm | Ø 200mm is equipped with the machine |

11 | Milling Head Spindle Z axis Stroke | L = 100 mm |

12 | Hydraulic Drive Workpiece Clamp Bracket | 1 set | 1 set of pump station; Special design and standard brackets driven with oil cylinder |

13 | Electricity Power Specification | 3P AC380V,50Hz,15kW for China mainland |