A. Function of SXBJ-12 Long Stroke Plate Edge Milling Machine:

1. This heavy duty Edge Milling Machine is for milling out high precision grooving on edges of metal plates, for the purpose of welding preparation;

The finished workpiece: Grooved steel plate delivered from the Wuxi JACK SXBJ-12 Plate Edge Grooving Machine: (Fig.1)

2. With the milling angle of 0°~ 90°, not only the common seen 0° straight edge perpendicular end face, but also 90° parallel top surface of workpiece can be milled;

1) Milling on the 0° straight edge perpendicular end face, with Wuxi JACK long stroke machine for cutting groove: (Fig.2)

2) Milling on the 90° parallel top surface, with Wuxi JACK Sheet Metal Plate Edge Milling Machine: (Fig.3)

B. Structure and Main Units in the SXBJ-12 Long Stroke Plate Edge Grooving Machine:

1. Milling Unit in SXBJ-12 Sheet Metal Plate Edge Milling Machine:

1) The upright milling column is being fixed on horizontally movable platform, which is driven manually, with screw gear through reducer, to control movement along Z Axis. Counter scale is used in the machine for this purpose;

2) Counter sensitivity is 0.1mm. Also, handwheel is used for fine adjustment, adjustment precision is 0.8mm/rev.;

The handwheel and counter for adjusting on feeding of milling head in the SXBJ-12 model machine: (Fig.4)

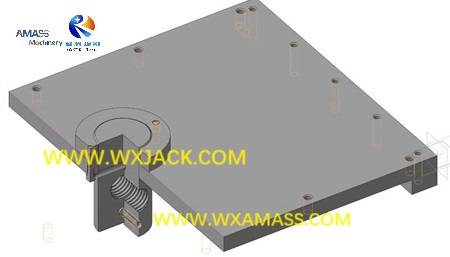

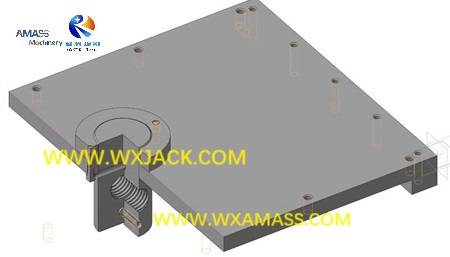

3) To eliminate backlash in nut platform connection and screw nut mechanism, design similar to showed on figure 5 shall be used in the Edge Milling Machineas below:

The moving platform installation in the SXBJ-12 model machine: (Fig.5)

2. The Vertical Milling Column Fixation in the SXBJ-12 Long Stroke Plate End Grooving Machine:

1) Column fixation to horizontal movement platform is made with use of adjustment pins, for strong fixation of its position, to exclude possibility of incorrect installation;

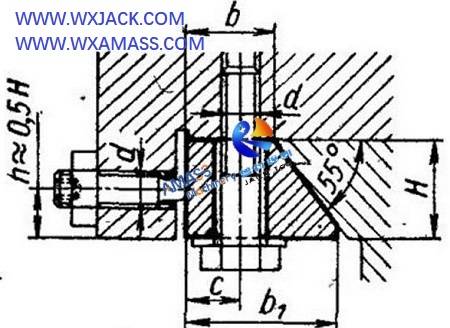

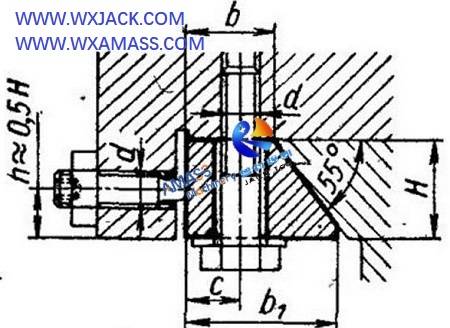

2) To ensure milling precision and high rigidity during milling process, movable platform, clamping pads and wedge shall be made according to scheme similar to showed on figure 6 as below:

3) The design sketch on slant guiderail for feeding of milling head, in the SXBJ-12 End Sheet Metal Grooving Machine: (Fig.6)

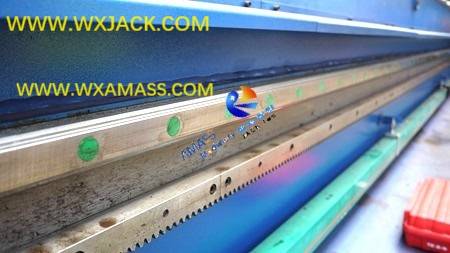

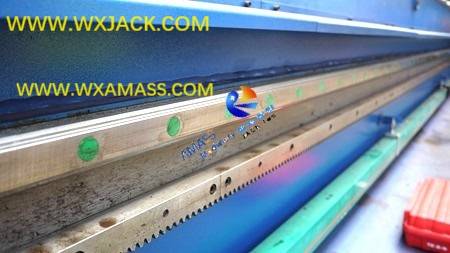

3. Guiderails of Milling Head Movement along X and Y axis in the SXBJ-12 Long Stroke Plate Edge Milling Machine:

1) Guides of carriage in this machine shall be machined after welding, it is not allowed to have any thermal cutting marks on working surfaces;

2) These guiderails are heavy duty precise linear ball bearing guiderails, assembled onto mechanical bed of the machine;

3) The superior quality HIWIN guiderail assembled in the Wuxi JACK Sheet Metal Plate Edge Milling Machine: (Fig.7)

4. Rotation of Milling Head for Adjusting on Milling Angle in the SXBJ-12 Sheet Metal Plate Edge Grooving Machine:

1) In this advanced control Edge Milling Machine, rotating of the milling head is driven with motor, detected with encoder, indicated with angle ruler, and managed with HMI (Human machine interface);

2) Rotating angle can be controlled with control panel of milling head carriage, rotation angle step is 0.1 degree. On each milling head metal protective cover shall be installed;

3) The HMI Milling angle management in the Wuxi JACK SXBJ-12 Plate Edge Grooving Machine: (Fig.8)

C. Workpiece Steel Plate Feeding System in the SXBJ-12 Sheet Metal Plate Edge Milling Machine:

1. Feeding system of this heavy duty machine consists of roller tables, 4 pieces of racks driven with hydraulic push devices, with 4 pieces of lifting hydraulic devices;

2. According to workpiece width in the machine, thrust pins are installing into the hydraulic push devices;

3. Workpiece moves forward with thrust pins and hydraulic push devices;

4. After workpiece is placed on the machine working table, it clamps by hydraulic jacks on the upper beam of this Edge Grooving Machine.

D. Electric Control System of the SXBJ-12 Long Stroke Plate End Grooving Machine:

1. Milling head driving load indicator (Ammeter) is installed on control panel or on rear side of the milling heads;

2. And motor protects against overcurrent is installed in control box of the Edge Milling Machine moving carriage;

3. All electric components of each milling unit should be installed into the independent electric cabinet of the milling head carriage, fixed on the side of milling units’ column through vibration dampers.

E. Technical Parameters of SXBJ-12 Sheet Metal Plate Edge Milling Machine:

SXBJ-12 Long Stroke Plate Edge Grooving Machine |

Plate Thickness Processing Range | 6–50 mm |

Plate Maximum Processing Zone Length | 12000 mm |

Plate Maximum Processing Width | 2500 mm |

Plate Maximum Weight | 40 Tons |

Milling Accuracy | Bevel Processing Accuracy | ± 1° |

Finished Surface Roughness Grade | ≤ 6,3 |

Milling Head | Model | ELONG MU-6S (Taiwan) |

Quantity of Milling Units | 2 |

Milling Head Power | 11 kW |

Spindle Rotation Speed | 75/115/165/240/345/505 (6 steps) rpm |

Permissible Miller Diameter | 125–250 mm |

Spindle Taper | ISO50(7/24) |

Spindle Diameter | 128,57 mm |

Milling Head Turning | Type | Motorized, with encoder |

Rotating Style | With control panel, rotation step 0.1 degree |

Rotation Motor Power | 0.4×2 kW |

Milling Head Rotation Angle | Milling unit No. 1 | -45°... +45° |

Milling unit No. 2 | 0°... +90° |

X Axis Movement | Type | gear rack and pinion |

Working Speed, | 0.15-1 (Stepless, with inverter) m/min |

Idle Speed | 4 m/min |

Carriage Moving Motor Power | 2.2×2 kW |

Y Axis Movement | Type | Screw and nut gear |

Milling Head lifting motor power | 1.1×2 kW |

Z Axis Movement | Type | Manual, through reducer |

Control type | Visually, with counter (sensitivity 0,1 mm) |

Milling head Z Axis feeding rate | 0.8 mm/rev. |

Milling head feeding within Z Axis | 250 mm |

Machine Total Power | ~35 kW |

Hydraulic Oil capacity | 250 L |

Hydraulic Clamping Jacks Quantity | 18 pcs |

Distance between Hydraulic Clamping Jacks | 650 mm |

Alignment Fender Units | 6 pcs |

Working Zone Lighting | Local lighting on each milling head |

Machine Working Conditions | From -10℃ to +40℃, Three Phase 380V 50Hz |

Machine Weight | Machine Weight | ~22 Tons |

Feeding Table Weight | ~3 Tons |

Overall Weight | ~25 Tons |