A. The Function and Applicable Workpiece of Custom Made Oxy-fuel Flame 5 Axis CNC Pipe Cutting Machine:

1. Wider Range of Workpiece Diameter Range than Conventional Φ600mm Grade CNC Pipe Intersection Cutting Machine:

1) In this applicating case, customer need to produce beveled pipe with max. diameter of Φ660mm, which is slightly bigger than the conventional size Φ600mm series Flame 5 Axis CNC Pipe Cutting Equipment;

2) Besides, the smallest diameter is Φ48mm, compared with the minimum Φ80mm in Φ600mm series;

3) Correspondingly, the workpiece chuck claw fixture in this CP5-660/12 Flame 5 Axis CNC Pipe Cutting Machine need to be tailor made: (Fig.1)

2. Cutting Way in Oxy-fuel Flame 5 Axis CNC Pipe Cutting Equipment:

Thickness of pipe wall is in the range of 5mm~ 50mm, which is applicable for Oxygen Acetylene flame cutting;

3. Beveling in Flame 5 Axis CNC Pipe Cutting Machine: (Fig.2)

The chamfering angle in this CP5-660/12 CNC Pipe Intersection Cutting Machine is in the range of -45°~ +45°, which is controlled with A axis and B axis;

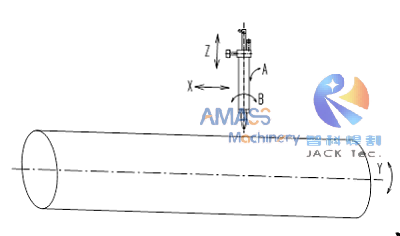

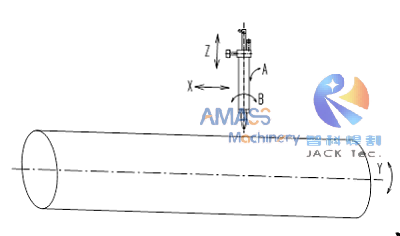

4. Correspondingly, the X/Y/Z/A/B axis in Flame 5 Axis CNC Pipe Intersection Cutting Machine is shown as below: (Fig.3)

B. Technical Features and Main Units in Flame 5 Axis CNC Pipe Intersection Cutting Machine:

1. Electric Control System in Oxy-fuel Flame 5 Axis CNC Pipe Cutting Machine:

In this 5 Axis CNC Pipe Cutting Machine, 4 axis are interlocked:

1) X axis for controlling cutting torch along pipe length;

2) Y axis for managing pipe rotation;

3) A axis for cutting torch tilting along pipe radius;

4) B axis for cutting torch tilting along pipe length direction;

5) Only the Z axis for cutting torch elevation is controlled independently in the 5 Axis CNC Pipe Cutting Machine;

2. Operating Station in Oxy-fuel Flame 5 Axis CNC Pipe Cutting Equipment: (Fig.4)

1) Shown in the above photo, considering the small diameter pipes (Φ660mm) and corresponding short height of the CNC Pipe Cutting Machine, standing type operating stand with CNC controller assembled on its top section is appropriate: (Fig.5)

2) Shown in the above photo, CNC and software have friendly Human Machine Interface, easy to command and operate, professional control hardware and software used for 5 Axis CNC Pipe Cutting Machine, and has the merit of convenient program, easy learning and available upgrade;

3. Mechanical System in CP5-660/12 Oxy-fuel Flame 5 Axis CNC Pipe Cutting Machine: (Fig.6)

1) Shown in the above photo, the horizontal beam for pipe lengthways travel is fixed at the top section of the CNC Pipe Cutting Equipment, avoiding spark generated during cutting process damaging guiderail;

2) Base bed of the CP5-660/12 5 Axis CNC Pipe Cutting Machine is in the form of solid box frame, which is installed firmly into workshop floor;

3) The longitudinal and vertical moving unit of cutting torch are guided with precise ball bearing linear guideway: (Fig.7)

4) Shown in the above photo, workpiece holding in CP5-660/12 5 Axis CNC Pipe Cutting Machine is chuck claw type. Comparatively, for large specifications, such as Φ2500mm CNC Pipe Intersection Cutting Machine, it is friction roller type;

4. Drive and Transmission System in CP5-660/12 Oxy-fuel Flame 5 Axis CNC Pipe Cutting Machine:

1) The precision gear reducers of the 5 axis CNC Pipe Cutting Equipment are imported from Germany, of small clearance and high accuracy;

2) Servo drive is JP Panasonic A.C. system, reliable and stable. In one set of the 5 Axis CNC Pipe Cutting Machine, there are 5 sets of servo driver and servo motor;

5. In a word, with 20 years of development, CP series CNC Pipe Cutting Machine is the best solution for customers who has the demand on pipe cutting and beveling.

C. Technical Specifications of CP5-660/12 Oxy-fuel Flame 5 Axis CNC Pipe Cutting Machine:

Below is specification of 5 Axis 600/12 Oxy-fuel Flame 5 Axis CNC Pipe Cutting Equipment:

Model Technical Parameter | CNC-CP5 660/12 Flame 5 Axis CNC Pipe Intersection Cutting Machine |

Valid Diameter Range of Pipe | 48 ~ 660 (mm) |

Valid Pipe Length Range | 1000 ~ 12,000 (mm) |

Valid Pipe Thickness Range | 5~50 mm for flame cutting |

Valid Cutting Speed | 100 ∼ 1000 mm/min. |

Idle Speed of Cutting Torch | 4000 mm/min. |

Beveling Angle Range for Groove | ±45° |

Valid CNC Control Axis | 5 Axis of X/Y/Z/A/B |