Outline on Wuxi JACK CNC H Beam End Face Milling Machine:

1) Business Achievement: Over the past decade, Wuxi JACK have delivered hundreds sets of CNC H Beam End Face Milling Machine of various models for customers in China and abroad, and gained high appraisal and word of mouth from them;

2) Attached photos show Wuxi JACK CNC H Beam End Face Milling Machine of various models and CNC systems taken at different customer sites.

1. Background of Numerical Control H Beam End Facing Machine:

1) Developing History of CNC H Beam End Milling Machine evolved from the year of around 2014~ 2015, upgraded on the basis of ordinary models A.C. relay controlled DX series H Beam End Face Milling Machine. The purpose is for ease and convenience of machining workpieces with round and any other special cross section shape;

2) Traditional Workpieces: As we know, DX series H Beam End Face Milling Machine is originated for milling on H Beam/ I Beam/ BOX Beam use, which involves “simple” working trace of straight edge and 90° right angle. At that time, the largest selling model is DX12xx/ DX15xx series;

3) More Demand on Machine Capability: Over the past decade, with the development of steel structure projects, workpieces applied in these projects witness developing trend of larger size and more complicated cross section, which poses demand on DX series machine also: One is larger model, for example, DX6080; The other is numerical control CNC H Beam End Face Milling Machine.

2. Advantages of Numerical Control CNC H Beam End Facing Machine:

1) Powerful Capability of CNC H Beam End Milling Machine:

a) This series has strong capability on end face milling workpieces with round/ sharp angle/ Any types of irregular cross section;

b) In conventional relay control machines, milling head can only travels along trace of either straight up/ down, or straight forward/ backward;

c) So, when it comes workpieces like tank/ pipe etc. operator needs to spend fairly long time to fret over facer blade alignment with end face of workpiece;

d) In contrast, in CNC control H Beam End Face Milling Machine, milling trace of facer blade is calculated/ monitored by means of CNC controller, which any contour of end milling is easily available;

3) Besides, there is workpiece library in backstage operating system of CNC controller in CNC H Beam End Face Milling Machine, in which common seen types of workpiece cross section, including circle/ triangle/ arc, etc., can be selected within seconds;

4) In all, with introduction of CNC controller, productivity of CNC H Beam End Facing Machine is raised 10% ~ 20%, and precision on end milling contour is also improved in an order of magnitude. For detail, please check product section of CNC-DX3530 and CNC-DX3535 models machine.

3. Technical Features of CNC H Beam End Face Milling Machine:

1) Drive System and Control in CNC H Beam End Face Milling Machine:

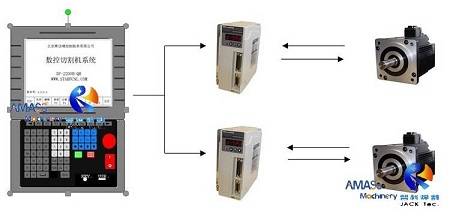

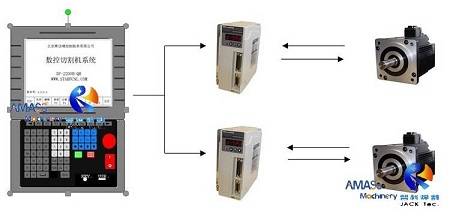

a) Shown in below sketch, in CNC type machines, drive system is servo motor and encoder, instead of Y series asynchronous motor in conventional models of the equipment;

CNC electric closed loop control system: (Fig.1)

b) Control on end face milling job is closed loop, with CNC system as core element, and encoder as negative feedback, instead of open circuit in conventional relay control equipment;

2) Milling Speed Control in CNC H Beam End Face Milling Machine:

In CNC models machine, end face milling is managed with CNC controller, instead of A.C. inverters in conventional equipment;

3) Operation of the CNC H Beam End Face Milling Machine:

a) In CNC models machine, end milling function is realized on CNC system soft keys. So, operating panel is simplified into a very small operating pendant leaving only management on hydraulic workpiece rack;

b) Operation on CNC machines is intuitive and user friendly --- Just keying in parameters of the workpiece that to be end milled;

c) Operating interface in CNC system has multiple languages to choose from;

4) Valid End Face Milling Stroke (Workpiece Size) in CNC H Beam End Face Milling Machine:

a) The most matching size for CNC models machine is small ~ medium duty, up to CNC-DX3535;

b) Working stroke higher than 3500mm is not applicable for numerical control;

c) One reason is servo motor is usually applied in small and medium power, rather than high power of 5kW and above;

d) The other reason is, workpieces of large model machine usually have relatively simple cross section, which does not need numerical control.

4. Technical Parameters of the DX Series CNC H Beam End Face Milling Machine:

No. | Parameter | DX Series CNC H Beam End Facing Machine |

1 | Applicable Max. Workpiece Cross Section Size Height × Width= | (800 x 1000) ~ (3500×4000) mm |

2 | Workpiece Width Horizontal End Face Milling Speed | 100~800 mm/min | Working speed, controlled with CNC controller |

3 | Facing Carriage Idle speed in horizontal and vertical direction | 1400 mm/min | Constant speed |

4 | Workpiece Height Vertical End Face Milling Speed | 100~800 mm/min | Working speed, controlled with CNC controller |

5 | Horizontal and vertical Face Milling guide | Heavy duty linear guiderail, installed onto machine body |

6 | CNC System | Beijing STARTFIRE SF-2100C, or Shanghai FANGLING F2300/ 2400/ 2500 |

7 | Horizontal Driving Motor | (1.5~2) kW | Panasonic Servo A6 series |

8 | Vertical Driving Motor | (2.0 ~ 2.5) kW | Panasonic Servo A6 series |

9 | Milling Head Power | 7.5 kW | Made in Chinese mainland |

10 | Milling Head Spindle Revolution | 75~420 rpm | 6-grade Revolution adjustable |

11 | Diameter of Facing Cutter | Ø125~250 mm | Ø 200 equipped with machine |

12 | Milling Head Spindle Stroke | L=100 mm |

|

13 | Hydraulic Workpiece Rack | 1 set | 1 set of pump station; Quantity of racks depends on length of workpiece |

14 | Electricity Power Specification | 3P AC380V,50Hz,15kW for China mainland |