You may check the appearance, structure and application of LHT T frame Gantry I Beam SAW Machine of various specific design being put in operation at customer sites, and its installation at Wuxi JACK facility from attached photos.

1. Trait and Application of LHT T Frame Gantry H Beam Welding Machine:

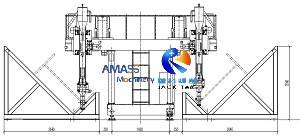

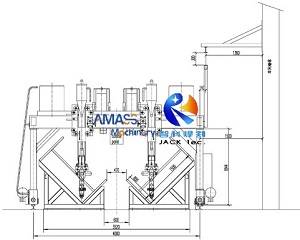

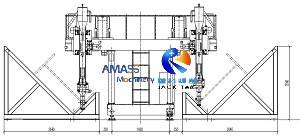

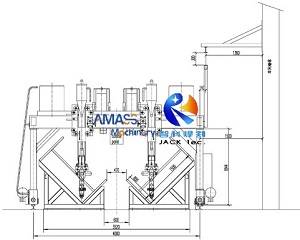

1) At first glance, LHT T type Gantry I Beam Submerged Arc welding machine looks very similar to LHA gantry type H Beam Gantry Welding Machine. To be specific, center control LHAZ H Beam Welding Machine. Or, if you observe it carelessly, you may probably confuse the LHT Gantry I Beam Welding Machine with LHA product: (Fig.1)

LHT T Frame Gantry I Beam Submerged Arc Welding Machine (Fig.2)

LHAZ Center Control H Beam Gantry Welding Machine (Fig.3)

2) If you observe carefully, you may identify the most important disparity between the LHT T frame and LHA gantry frame H Beam Welding Machine:

a) The LHT Gantry H Beam Welding Machine has its two pieces of workpiece laid on support in open structure, so LHT can be used for welding larger size of H Beam, and it has extensive accommodation on varying H Beam size. In theory, there is no confinement on dimension of H Beam to be available being welded on LHT Gantry I Beam Welding Machine;

b) While the LHA H Beam Gantry Welding Machine has its workpieces supporting rack surrounded in an enclosed frame. So, there is series of concrete models for corresponding fitting size range of H Beam: LHA4Z, LHA5Z, LHA55Z, LHA4C, LHA5C, etc.

2. The Relationship between LHT H Beam Welding Machine with LHC and LHA H Beam Gantry Welding Machine:

1) Connection between LHC and LHT gantry H Beam Welding Machine:

On the other hand, there is common point between T type LHT gantry I Beam Welding Machine and column type LHC I Beam SAW Machine:

a) Same as LHC column type I Beam SAW Machine, in LHT H Beam Gantry Welding Machine, because workpiece H Beam are put on the supporting tacks outside of the machine frame column, there is no limit to the extension of H Beam;

b) In this sense, for the same size of machine frame, H Beam welded with LHT T type automatic H Beam Welding Machine can be larger (web height) than gantry type LHA H Beam Gantry Welding Machine;

c) And also same as LHC I Beam SAW Machine, such kind of structure can accommodate H Beam of various web sizes, so for T type LHT H Beam Welding Machine, there is no variation in machine model to differentiate, just one model of LHT fitting for all size of H Beam;

2) Connection Among LHT, LHC and LHT I Beam SAW Machine:

a) In a sense, LHT gantry H Beam Welding Machine is something like bridging the gap between Column style LHC and gantry style LHA H Beam Welding Machine;

b) The three kinds of I Beam SAW Machine share the same theory of submerged arc welding, and therefore same kind of SAW welding power source and auxiliary welding units. They are kindred products under the same product family of I Beam Submerged Arc Welding Machine. The development of T type LHT is made on the basis of LHA H Beam Gantry Welding Machine: (Fig.4,5)

3. The Driving Power for Operation of LHT H Beam Gantry Welding Machine:

Unlike heavy power involved during assembling step of H Beam Assembly machine, and during straightening step in H Beam Straightening machine, which need hydraulic system to provide power momentum, in LHT T frame gantry H Beam SAW machine (And LHC, LHA H Beam Gantry Welding Machine also), driving power is from motor reducer for mechanical system (machine body), electric power for SAW welding power source, and pneumatic system for arc tracing unit. (Fig.6)

4. Technical Parameters of LHT H Beam Gantry Welding Machine:

Below are specifications of this LHT T type High Quality Gantry H Beam Welding Machine:

LHT Gantry I Beam SAW Machine (I Beam Submerged Arc Welding Machine) |

Parameter | Specification | Note |

Operator Working Position | Beneath T frame, between 2 supporting racks |

Applicable H Beam Flange Width (mm) | 200 ~ 800 |

|

Applicable H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

Applicable H Beam Web Height (mm) | 200 ~ 2000 |

|

Applicable H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

Power Consumption of SAW Power | 2 x 80 kW |

|

Power Consumption of LHT Main Machine | 9 kW |

|

H Beam Length (mm) | 4000 ~ 15000 | Can be special made |

Gantry Travel Rail Length (mm) | 18000 |

|