Background: The Automated H Beam Assembly Machine in the first photo was also taken from an an Wuxi JACK produced automatic H Beam Production line.

1. Usage of Z15~Z20 Automated H Beam Assembly Machine:

1) Output: Z15~ Z20 Automated H Beam Assembly and Tack Welding Machine is a typical group of H Beam Production Machine, producing half finished product of welding H Beam:

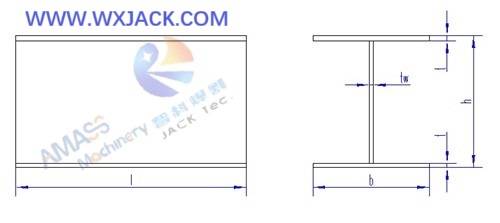

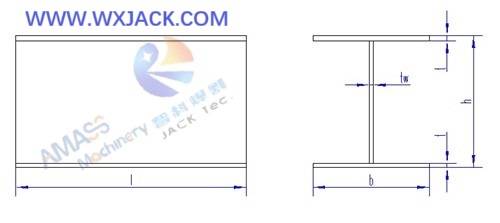

Indication on assembled H Beam from H Beam Assembly Machine: (Fig.1)

2) Subsequent Machine: As you can observe from the first photo, the LHC H Beam SAW Machine deployed in the next station of this Automated I Beam Assembly Machine;

3) Central Unit of Hydraulic Drive in H I Beam Assembly Machine:

a) This series of Z15~Z20 also covers automatic welding H Beam Assembling machine of hydraulic drive;

b) Mainstream on Drive: Today it accounts for majority of H Beam assembly and tack welding operation, benefiting from advantages of high and persistent quality, as well as saving variable cost of manual labor, as we discussed in the previous product of “Z15~Z20 Automatic H Beam Assembly Machine with Tack Welding”;

c) This is the reason we use large section of the product family of H Beam Assembly Machine to have presentation on it.

2. The Three Working Modes in Automated I Beam Assembly Machine:

In the previous product section, we mentioned the three working modes of MANUAL/ SINGLE/ AUTO in the H Beam Production Machine of H Beam Assembly Machine. Here we will explore it in further detail:

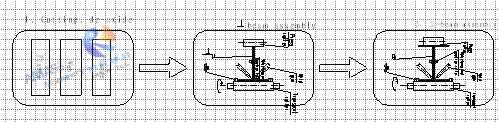

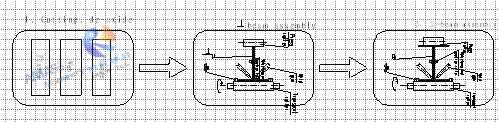

3 critical process steps operated in H Beam Assembly Machine: (Fig.2)

Selecting buttons for 3 working modes in H Beam Assembly Machine: (Fig.3)

1) Manual mode in Automated H Beam Assembling Machine:

This is the default working mode of the H Beam Assembly Machine. Which means, the machine works under Manual mode automatically after power on;

This mode is for trial run, commissioning, and trouble shooting of the H Beam Assembly Machine;

With start of oil pump, the Automated I Beam Assembly Machine will have operations of:

a) Forward and Backward of drive, input and output conveyor;

b) Clamp and release on oil cylinder of the pulling rod system;

c) Press and release of gantry roller of the I H Beam Assembly Machine;

d) Start on oil cylinder of flange and web alignment unit;

e) Extension and retreat of positioning unit in the I H Beam Assembly and Tack Welding Machine;

f) Upward and downward of welding torch;

g) Start and stop of welding power source in the I H Beam Assembly Machine;

2) Single Cycle in Automated H Beam Assembly Machine: (Fig.4)

a) Definition: This automatic H Beam Production Machine welds a segment of welding seam during period T, and advances the assembled H Beam a distance at the same time. This is called Single Cycle of the H Beam Assembly Machine;

b) Process Parameters: We use VL (velocity low) for conveyor speed during welding; And VH (velocity high) for conveyor speed during idle travel; Period t1 means welding cycle;

c) Welding Segment: Within period t1 of the Automated H Beam Assembly Machine, conveyor sends H Beam forward in the inverter control adjustable speed VL; Meanwhile, welding power source finishes a segment of welding seam on the workpiece;

d) Idle Segment: During period T-t1, welding power source of the I Beam Assembly Machine stops working, and conveyor sends the H Beam a distance in speed VH;

e) Thus finishes one time of Single Cycle in the operation of Z15~Z20 Automated H Beam Assembling Machine;

3) Auto Cycle in Automated H Beam Assembly Machine:

a) Definition: The automatic and continuous running of Single cycle is Auto cycle.

b) Start On Auto Cycle: With power on and oil pump start, no matter the Automated I Beam Assembly Machine is in Manual mode or Single Cycle mode, just press the Auto Cycle button on the operating pendant, the H Beam Assembly Machine will be switched to Auto Cycle;

c) Continuous Auto Cycle: If operation of the automatic H Beam Production Machine is correct and conforms to requirement of welding process technology, the entire piece of H Beam can be assembled and tack welded in Auto Cycle mode.

3. Technical Parameters of Z15~Z20 Automated H Beam Assembly Machine:

Below are specifications of the Z15~Z20 H Beam Production Machine Automated I Beam Assembly Machine with Tack Welding (H Beam Assembling Machine):

Model | Z15~Z20 Automated H Beam Assembly and Tack Welding Machine |

H Beam Web Height | 200 ~ 1500/1800/2000 mm |

Suitable H Beam Web Thickness Range | 6∽32 mm |

Suitable H Beam Flange Width Range | 200∽800 mm |

Suitable H Beam Flange Thickness Range | 6∽40 mm |

Suitable H Beam Length Range | 4000∽12000 mm |

Max. H Beam Weight Range | 20 Ton. |

Working Mode | Manual/Single/Auto |

Web and Flange Alignment Style | Self Alignment (Automatic), controlled with PLC |

Tack Welding Style | Automatic CO2 tack welding |

Assembly and Tack Welding Speed | 0.5 ~ 6 m/min. |

CO2 Gas Shielded Welding Power Source | Panasonic KR350 or HUAYUAN NB350 |

Operator | 1 operator |

Assembly and Tack Welding speed (mm/min.) | 500 ~ 6000 |