1. Technical Feature of Standard HGK Series Adjustable Welding Rotator by Leadscrew:

The standard models in this product section is the fundamental of HGK model sub group. Here the description “fundamental” means:

1) These ranges of Weld Roller Bed are representative of HGK series leadscrew adjustable type ;

2) All variations of the Welding Turning Roller (In terms of structure and specification) are made on its basis;

3) These standard models have the most extensive application in the HGK series leadscrew adjustable type.

2. Structure and Formation of Standard HGK series Adjustable Welding Turning Roll by Leadscrew:

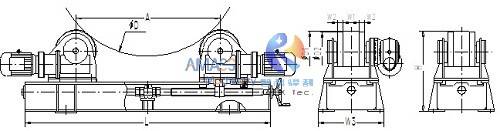

Side view of a set of typical, or elementary HGK model leadscrew adjustable type see below sketch:

Design sketch: (Fig.1)

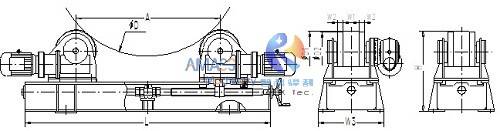

A set of Wuxi JACK standard leadscrew adjust type Welding Rotator: (Fig.2)

From above we can see framework of the standard HGK models leadscrew adjusting type:

1) Constitutes: One set of the product consists of: One set of driving section Weld Roller Bed, and one set of follower section;

2) Form Up:

The driving way of the Welding Roller Bed consists of pedestal, rectangular guideway, leadscrew and its handwheel, two pieces of Welding Turning Roller, and its carriage, motor reducer;

3) Drive and Transmission of HGK Series Leadscrew Adjust Welding Turning Roll:

a) With this type of product, there are 2 sets of motor reducer, installed at left and right side of the Weld Roller Bed respectively;

b) The motor reducer in the HGK series leadscrew adjust Welding Rotator is cycloidal gear reducer, which in turn drive transmission unit of worm gear reducer. Such kind of combination is the most common used type;

4) Adjustment with Leadscrew in the HGK Welding Rotator:

a) When adjusting center distance of the two pieces of Welding Turning Roll, turning the handwheel by hand (There is special made electric way of turning handwheel, which we will discuss in the product section of “HGK Special Made Electric Travelable Adjustable by Leadscrew”);

b) The 2 sets of carriages move along the rectangular guideway of the Weld Roller Bed synchronously in opposite direction. Which means, for enlarging the center distance between the Welding Turning Roller, the 2 carriages move away from each other; For decreasing the center distance, the 2 carriages travel toward each other;

5) Material of Welding Turning Roll:

a) For small and medium tonnage of HGK Weld Roller Bed adjusted with leadscrew, its Welding Turning Roller can be the joint of rubber and metallic ones;

b) For larger model of the leadscrew adjusting Welding Rotator, such as 10 Ton or above, very often the Welding Turning Roll are full metallic type:

Rubber Rollers: (Fig.3)

Fully metallic rollers: (Fig.4)

6) Fixation of the Welding Roller Bed: There are mounting holes in the pedestal of these leadscrew adjustable models;

7) Ready to made Handling for HGK Welding Rotator: The small size of Weld Roller Bed have very compact construction, easy for movement, storage, changing location, and operation;

8) User friendly Manipulation in the HGK Small Welding Rotator:

Same as HGZ series Self Adjustable, in HGK series leadscrew adjusting type, the revolving speed of the Welding Turning Roll, which is the operating speed of welding/ painting on the workpiece, adopts with technique of digital managing and displaying, which is intuitive and easy to check, reducing operating difficulty of Adjustable Welding Rotator by Leadscrew. In this sense, it is a kind of efficient welding rotating equipment;

9) Supplementary Notes:

There is counterpart product of standard models in HLK series adjusted with bolt. For detail, please check product section of “HLK Standard Roller Bed Stationary Adjustable by Bolt”.

3. Technical Parameters of Standard HGK series Adjustable Welding Rotator by Leadscrew:

Standard Structure HGK series Adjusting Welding Rotator by Leadscrew |

Model | HGK2 | HGK5 | HGK10 | HGK20 | HGK40 | HGK60 |

Max. loading (Ton) | 2 | 5 | 10 | 20 | 40 | 60 |

Workpiece Size(mm) | D | ø250~1800 | ø 250~2300 | ø 320~2800 | ø 500~3000 | ø 600~4200 | ø 700~5000 |

Roller diameter and width (mm) | PU roller | D1 | 200 | 250 | 300 | 350 | 400 | 450 |

W1 | 80 | 100 | 120 | 120 | 120 | 120 |

Metallic roller | D2 | 190 | 240 | 290 | 340 | 392 | 444 |

W2 | 16 | 20 | 38 | 45 | 50 | 70 |

Linear speed(mm/min.) | 100-1000 VFD |

Motor power(kW) | 2×0.18 | 2×0.37 | 2×0.55 | 2×1.1 | 2×1.5 | 2×1.5 |

Roller distance (mm) | A | 300~950 | 400~1300 | 480~1400 | 600~1800 | 800~2000 | 880~2200 |

Above are the standard parameters of the Welding Rotator, also we can design on customer requirement. |