A. Usage and Function of HB200 Single Working Table Two Axis Revolving and Tilting Welding Positioner:

1. Feature: HB200 model belongs to Heavy duty Two Axis Welding Positioner, which has max. loading capacity of 20 Ton weight workpiece;

2. Function: Equipped with one piece of Φ2500 mm Rotary Welding Table, it can be used for carrying out manual and or automatic welding on short length and heavy weight structure members of various design;

3. This standard type of Weld Positioner can be adjusted to the best position for welding by its Welding Turning Table and workpiece revolve and tilt, after fixed with workpiece by means of fixture:

Wuxi JACK Welding Turntable secured with Workpiece operates at customer site: (Fig.1)

4. There is a range of specifications of HB series standard structure Two Axis Revolving and Tilting Welding Positioner to choose from, based on various customer welding requirement.

B. Structure of HB200 Single Working Table Two Axis Revolving and Tilting Weld Positioner:

1. Rotary Welding Table of HB200 Two Axis Welding Positioner:

1) Welding Turning Table of HB200 model can revolve in any direction within its plane. With control buttons on the control board, continuous or jog revolve in forward or reverse direction, as well as stop can be realized;

2) Welding Turning Table Revolve Transmission in HB200 Two Axis Weld Positioner:

Chain of transmission for Welding Turntable rotation in HB200 Two Axis Revolving and Tilting Welding Positioner: Revolve brake motor→ Double stage reduction gear→ Small gear→ Cross roll bearing→ Welding Turntable revolve;

3) The self-lock function for the Rotary Welding Table is acquired from worm gear reducer. That is, when workpiece is under tilt condition, and loading eccentricity is within stipulated range, workpiece will not revolve on its own;

4) Loading Eccentricity of Rotary Welding Table:

This is restricted with loading capacity of the HB200 welding positioning equipment:

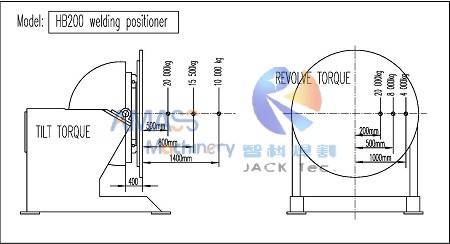

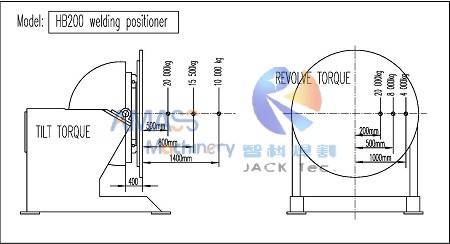

The relationship between eccentricity and revolving capacity in this Weld Positioner please see below design sketch: (Fig.2)

2. Welding Turning Table Tilt in HB200 Single Working Table Two Axis Revolving and Tilting Welding Positioner:

1) The Welding Turntable can be tilted and stopped within the range of 0~900;

2) There is electro-magnetic brake on the drive motor, giving self-lock ability for motor tilting, so that Rotary Welding Table will not tilt and move by itself within rated loading capacity;

3) The extreme position of Welding Turntable tilt is controlled with limit switches:

Welding Turning Table Tilting Angle Control: (Fig.3)

4) Rotary Welding Table Tilt Transmission in Two Axis Welding Positioner:

Chain of transmission for tilting of workpiece is: Electro-magnetic brake motor →Double stage cycloidal gear reducer →Double stage gear →Welding Turntable tilt;

5) The corresponding constant tilting revolution speed is 0.15 r/min;

6) The height between loading gravity center of the HB200 Weld Positioner to Welding Turntable surface is restricted with loading capacity. Its relationship sees Fig.2 in the above.

3. Conduction of Welding Current in HB200 Two Axis Revolving and Tilting Weld Positioner:

The welding current of the Welding Positioner is conducted thru the carbon pole on the shaft of the Welding Turning Table, then thru flexible hose to the bottom of the mechanical base bed:

Welding Current Conduction Element in Wuxi JACK HB models Two Axis Revolving and Tilting Welding Positioner: (Fig.4)

4. Drive and Transmission Unit in HB200 Two Axis Revolving and Tilting Weld Positioner:

1) All the motor reducers of the Welding Positioner are lubricated with lubricating oil, and open type gear and bearing are lubricated with grease;

2) The digital panel meter on the control board of Weld Positioner indicates Rotary Welding Table revolve speed. If the indicated speed is not identical with the actual speed, please adjust the aligning potentiometer inside control board accordingly;

3) During operation period, when overload or short circuit happened with the Rotary Welding Table drive motor, A.C. inverter will alarm automatically, and stop output; Or if motor cable breaks, its indicating lamp will illuminate;

4) The revolve and tilt motor reducer use brake motor to make sure downright safe operation of the HB200 Heavy duty Two Axis Welding Positioner, whenever workpiece is stopped at any angular position.

C. Technical Parameters of HB200 Two Axis Revolving and Tilting Welding Positioner:

No. | Model | HB200 Single Working Table Two Axis Revolving and Tilting Weld Positioner |

1 | Loading Capacity | 20,000 kg |

2 | Workpiece Revolve Linear Speed | 0.05-0.5 rpm |

3 | Workpiece Tilt Speed | ≈0.15 rpm |

4 | Welding Turning Table Diameter | Φ2500 mm(for easy stuff container) |

5 | Max. Eccentricity Distance | 200 mm |

6 | Max Gravity Center Distance | 500 mm |

7 | Workpiece Tilt Range | 0°-90°mm |

8 | Welding Turning Table Revolve Diameter at 900 | ≤3200 mm |

9 | Workpiece Revolve Speed Adjustment | Revolve speed is VFD. (Ordinary brake motor) 14

|

10 | Welding Turntable Tilt Speed Adjustment | Tilt speed is constant (Ordinary brake motor) |

11 | Control Box | One set |

12 | Power | 380 V, 50 Hz, 3 Phase |