Manufacturing Site of DX1530 H Beam End Milling Machine:

1) Attached is mechanical main frame of a set of DX1530 at Wuxi JACK workshop;

2) You can see there is another set of smaller one standing behind it --- DX0820 in blue color.

A. Usage of DX1530 Steel Structure H Beam End Face Milling Machine:

1) Usage: DX series Welding Structure Member H Beam End Face Milling Machine is for completing end face machining on both ends of welding or rolling steel structure members, including H Beam/ I Beam/ BOX Beam;

2) Work Station: In a Steel Structure workshop, this machine is deployed at finishing working station to H Beam Production line or BOX Beam Production Line;

3) Strong Points: This machine has friendly operation and economical running. It is indispensable equipment for professional producers in Steel Structure/ Piping/ Petro-Chemical Industries;

4) Application: DX1530 can be used in industries of Steel Structure/ Chemical/ Pressure Vessel/ Shipbuilding/ Bridge Construction/ Machinery Manufacture.

B. Structure and Working Principle of Welding Structure Member H Beam End Facing Machine:

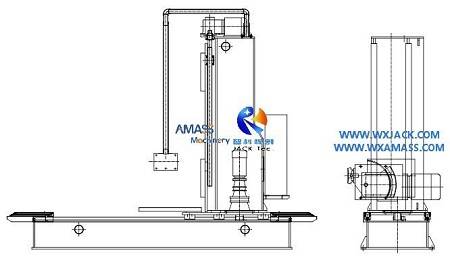

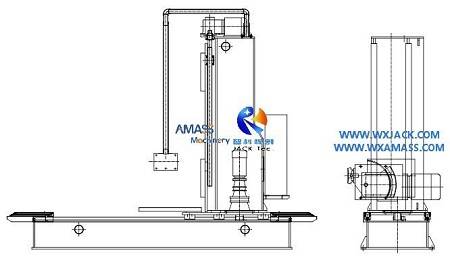

1. Design sketch on mechanical main frame of DX1530: (Fig.1)

2. Wuxi JACK H Beam End Face Milling Machine has Main Units of:

1) 7.5kW high power easy operation milling head: (Fig.2)

2) Consumables milling cutter;

3) Mechanical upright column, with milling head carriage installed: (Fig.3)

4) Mechanical horizontal base bed: (Fig.4)

5) Mechanical feeding system;

6) Electric control system;

7) Precise linear guiderail safeguarding unit;

8) Hydraulic workpiece bracket of the standard models H Beam End Milling Machine: (Fig.5)

9) Hydraulic pump station;

3. Milling Head Movement in H Beam End Facing Machine:

1) Along both horizontal direction (workpiece width) and vertical direction (workpiece height) guiderails are guided with heavy duty precise linear guiderail, featuring in strong loading capacity/ small clearance and high precision;

2) High precision linear guide rail in Wuxi JACK End Face Milling Machine: (Fig.6)

4. Operating Station in DX1530 Steel Structure H Beam End Face Milling Machine:

1) For small and medium DX15xx and other special models of I Beam End Milling Machine, operating panel is in the manner of hanging pendant, at the same height level as operating staff;

2) Please check the attached first photo;

3) This overhang operating pendant can be turned 360°, easy for operator to have cutter setting and monitoring;

5. The guiderail in the vertical column is protected with black color organ shield, preventing metal filings from splashing onto it and doing harm;

6. The guiderail in the horizontal bed is protected with telescopic nested cover, which is made from stainless steel. This protection unit has good sealing/ heat dissipation and long using life. Please check the 3rd photo;

7. Mechanical Main Frame of H Beam End Facing Machine:

1) Horizontal bed and upright column are all of welding structure, which are integrally annealed after fabrication, of high accuracy/ steadiness/ Non- deformation;

2) Please check the attached 4th photo;

8. Milling Head Adopted in DX series End Face Milling Machine:

1) As the most important unit of the machine, milling head is produced with professional Machine Tool Factory;

2) It has characteristic of reasonable structure/ reliable performance/ wide speed range/ good rigidity/ low noise/ high efficiency/ convenient operation;

3) Revolution of milling head facer blade can be modulated by means of hand shank according to size of cutter head;

9. Milling head can be revolved integrally 0°~ 45° along the its vertical installation board, so, groove can be made during work of the H Beam End Milling Machine. This is the unique feature of Wuxi JACK products. Please check the attached 5th photo;

10. The horizonal bed is equipped with manual lubricating pump, making good lubrication on the guiderails. Please check the attached 6th photo;

11. The milling cutter head in DX series machine is standard, which can be conveniently purchased in market. Material of facer blade is cemented carbide steel.

C. Technical Parameters of DX1530 Steel Structure H Beam End Face Milling Machine:

No. | Parameter | DX1530 Steel Structure H Beam End Facing Machine |

1 | Suitable Workpiece Max. Cross Section Size Height × Width= | 1500 ×3000 mm |

2 | Horizontal Way (Workpiece Width) End Face Milling Speed | 150~ 800 mm/min. | Stepless, Variable Frequency Drive, inverter control |

3 | Face Milling Carriage Idle speed in Horizontal and Vertical Direction | 1100 mm/min. | Fixed speed |

4 | Vertical Way (Workpiece Height) End Facing Speed | 150~ 800 mm/min | Stepless, Variable Frequency Drive, inverter control |

5 | Horizontal and Vertical Direction End Face Milling Movement Guide | Heavy duty Precise Linear guiderail, assembled onto Machine horizontal bed and upright column |

6 | Workpiece Horizontal Driving Motor | 2.2 kW | Y Series A.C. Asynchronous motor |

7 | Workpiece Vertical Driving Motor | 3.0 kW | Y Series A.C. Asynchronous motor |

8 | Milling Head Power | 7.5 kW | Made by Professional Supplier |

9 | Milling Head Tilting Angle | 0° ~ 45° | Adjusted by hand |

10 | Milling Head Spindle Revolution | 75 ~ 420 rpm | 6 grades Revolution adjustable |

11 | Diameter of Face Milling Cutter | Ø125~315 mm | Ø 200mm equipped with machine |

12 | Milling Head Spindle Z axis Stroke | L=100 mm |

13 | Hydraulic Drive Workpiece Bracket | 1 set | 1 set of pump station; Quantiy/ Structure of bracket depends on workpiece type and size |

14 | Hydraulic Specification | 3kW pump station; 5 MPa |