1. Hydraulic Drive Pulling Rod Boxes in H Beam Assembly Machine:

1) Critical Unit: The H Beam Production Machine of High Efficiency H Beam Assembly Machine in the attached first photo was taken from its input side, as you can find the hydraulic manipulator deployed in interval;

2) Function: It is used for carrying out first stage H Beam flange and web fitting up, along input conveyor of H Beam Assembly Machine;

Hydraulic drive pulling rod box (Manipulator) equipped in H Beam Assembly Machine: (Fig.1)

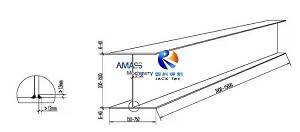

2. Operating on Z series High Efficiency H Beam Assembling Machine:

1) Function and Task: Z series H Beam Assembly and Tack Weld Machine is an essential H Beam Production Machine. It combines the two basic steps of H Beam fitting up and CO2 tack welding into one equipment, and fulfils these two tasks with one time pass of workpiece through the machine. In this respect, this H Beam Production Machine is a truly High Efficiency H Beam Assembling and Tack Welding Machine:

Process steps being carried out in H Beam Assembling Machine: (Fig.2)

2) Working Station of H Beam Assembly Machine as H Beam Production Machine:

Z series H Beam Assembly Machine is usually deployed in automatic and or semi-automatic H Beam Production Line. The other two basic H Beam Production Machine applied are:

a) LHA& LHC& LHT series H Beam Submerged Arc Welding Machine;

b) HYJ& YTJ series H Beam Straightening Machine;

The finished working parts being delivered is welding H Beam of various specifications, ranging in 1500~ 1800 mm web height for Z15 standard models of H Beam Assembly Machine:

Welding H Beam being produced from H Beam Assembly Machine: (Fig.3)

3. Working Modes of the Z series H Beam Assembly Machine:

1) Working Modes: The Z15~Z20 High Efficiency H Beam Assembly and Tack Weld Machine has three working modes to choose from: AUTO, SINGLE, MANUAL. For its introduction, please check product section of “Z15~Z20 Automated H Beam Assembly Machine with Tack Welding”:

Operator works on Wuxi JACK H Beam Assembly Machine at customer workshop: (Fig.4)

2) Switch among the three working modes in this H Beam Production Machine is made with the corresponding pushbuttons on operating pendant of the equipment, shown in the above picture;

3) Operating Panel: In the previous product section we introduced the three working modes of the High Efficiency H Beam Assembly and Tack Weld Machine. Attached please check operating pendant for the exported machine.

4. Operating Way of the Z series H Beam Assembly Machine:

In this section we will continue to discuss on operating process of the H Beam Assembly Machine, from the aspect of operating pendant:

Operating panel of I H Beam Assembly Machine: (Fig.5)

1) Single Mode Operation of the H Beam Assembly Machine:

a) Importance: Single mode is the basis of normal work of H Beam Production Machine H Beam Assembly Machine;

b) Usage of Single Mode: After confirming there is no issues with the equipment in Manual mode, first have trial run in Single mode. Do not jump to AUTO mode;

c) Default Working Mode of Machine: Under the condition the H Beam Assembling Machine is powered on and oil pump is started, no matter the machine is in Manual mode or Auto mode, just press the Single Cycle button on operating pendant, the H Beam Production Machine will be switched to Single Cycle;

d) Start On Single Cycle: Press the Single Cycle again, CO2 tack welding begins;

e) Continue on Single Cycle: At completion of Single Cycle in the H Beam Assembly and Tack Weld Machine, if it is still necessary to still work in Single Cycle, press the Single Cycle button again;

f) Switch to Manual Mode: If it is necessary to leave Single mode, press the Manual button;

g) Complete on Single Mode: At the time the H Beam Assembly Machine finishes assembling an integral piece of H Beam in Single mode, press Manual button, and press Output Conveyor Forward, the assembled H Beam will be sent to designated position;

2) Manual mode Operation of the H Beam Assembly Machine:

This mode is for commissioning and trial run on the equipment, to validate its performance. In this mode, the H Beam Production Machine works as a Z series Manual H Beam Assembly Machine;

3) AUTO Mode of the H Beam Assembling Machine:

Working Way: The continuous running of the Single mode is AUTO mode of the H Beam Assembling and Tack Welding Machine, as introduced in the first segment.

5. Technical Parameters of Z series H Beam Assembly Machine:

Below are specifications of the Z15~Z20 H Beam Production Machine Automatic High Efficiency H Beam Assembling Machine with Tack Welding:

Model | Z15~Z20 Self Alignment with Automatic CO2 Tack Welding H Beam Assembling and Tack Welding Machine |

H Beam Web Height | 200 ~ 1500/1800/2000 mm |

Applicable H Beam Web Thickness | 6∽32 mm |

Applicable H Beam Flange Width | 200∽800 mm |

Applicable H Beam Flange Thickness | 6∽40 mm |

Applicable H Beam Length | 4000∽12000 mm |

Assembling and Tack Welding Speed | 500 ~ 6000 mm/min. |

Input and Output Conveyor Power | 1.1kW x 2 |

Max. H Beam Weight | 20 Ton. |

Working Mode | Manual/Single/Auto |

Web and Flange Alignment Style | Self-Alignment (Automatic), PLC controlled logic |

Tack Welding Style | Automatic CO2 tack welding controlled with PLC and A.C. inverter |

CO2 Gas Shielded Welding Power Source | Panasonic KR350 or HUAYUAN NB350 |

Operator | 1 operator |

Assembly and Tack Welding speed | 500 ~ 6000 mm/min. |