Equipped with one or several sets of CNC control flame torch, the CNC Plasma Plate Cutting machine can cover the widest range of workpiece in terms of material and thickness for plate shape cutting.

1. Form Up and Usage of the CNC Plasma Flame Plate Cutting Machine:

1) Form Up of the CNC Plasma Cutting Machine:

a) As can be seen from the attached picture, the CG4000 CNC Plasma Cutting machine has three sets of CNC control single cutting torch: One for plasma shape cutting and two for flame shape cutting. Each of the three torches occupies one set of moving carriage solely:

Cutting torches of Wuxi JACK CNC Plasma Flame Plate Cutting Machine:

(Fig.1)

b) Here we stress that, in CG series CNC Strip Plate Cutting machine, another way of installing cutting torches is to combining plasma cutting torch with one of the flame cutting torch, so that one set of moving carriage can be saved (Less manufacturing cost of the CNC Plate Cutting Machine). For operation of the latter solution (Combined cutting torches), it is necessary to switch between plasma shape cutting and flame shape cutting by means of toggle switch, during working of the CNC Plasma Cutting Machine:

Cutting torch with both plasma and flame cutting in CNC Plate Cutting Machine:

(Fig.2,3)

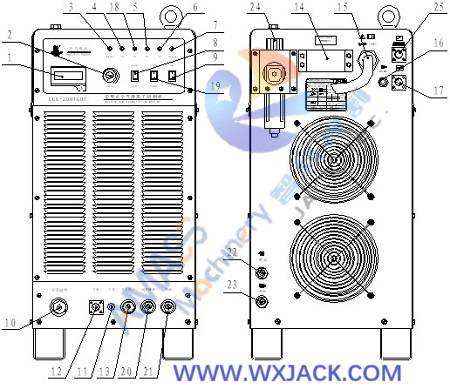

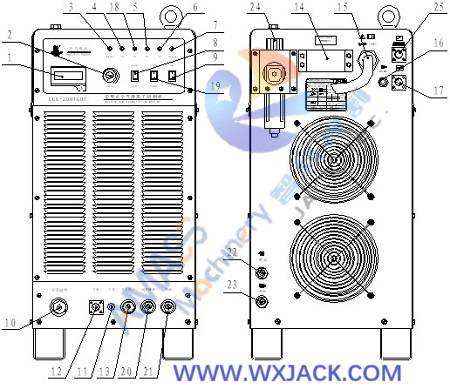

Operating panel of Wuxi JACK CNC Plasma Flame Plate Cutting Machine: (Fig.2,3)

c) While for the set up shown in the attached first picture: Plasma cutting torch occupies an individual carriage, the operation is simpler during working of the CNC Plasma Flame Plate Cutting machine. So, which kind of set up to choose is a compromise and depends which factor weighs heavier for customer: Convenient operation or lower cost;

2) Usage of the CNC Plasma Plate Cutting Machine:

a) This Gantry structure CNC Plasma Plate Cutting Machine also focus on metal plate shape cutting. Accommodating three sets of CNC cutting torch, customer can have three pieces of workpiece (Same shape and size) cutting in a row;

b) Meanwhile, with the add on of CNC flame cutting torch to the CNC Plasma Cutting Machine, the thickness range of plate shape cutting can also got expanded: Plasma shape cutting is for thin and medium thickness plate (Up to 45mm, majority fall within the range of below 25 mm); And currently flame cutting is the only feasible solution for thick metal plate (Up to 150 mm and special made for 200 mm);

3) Cutting Torch height controller in the CNC Plasma Flame Plate Cutting Machine: (Fig.4,5)

a) The workpiece (Metal plates) in CNC Plasma Flame Plate Cutting machine often do not have flat surface, especially for long length ones;

b) In plate shape cutting, maintaining constant distance between cutting tip and surface of workpiece is the prerequisite on getting high quality cutting parts. Please check product section of “Plasma and Flame Strip 4m CNC Plasma Plate Cutting Machine” for introduction on capacitance and arc voltage height controller for controlling flame and plasma cutting torch.

2. Daily Use of Plasma Power Supply in CNC Plasma Cutting Machine:

1) Daily using and maintaining of plasma power supply is critical for normal, consistent and high standard running of CNC Plasma Plate Cutting machine;

2) In this product section, first we have the topic of Plasma Power Supply Handling in CNC Plasma Flame Plate Cutting Machine: (Fig.6)

a) The plasma power supply should be cut off power before moving the CNC Plasma Plate Cutting machine;

b) The plasma power supply should be upright placement, instead of kept downwards during transportation. Do not have it in inverted placement;

c) When being hoisted, the plasma power supply should be kept at upright position, not lying position;

d) During long distance transportation of plasma power supply and its CNC Plasma Cutting machine, the equipment should be protected against infiltration of rainwater / moisture/ scattered placement (The components need to be secured firmly). Use proper packing material, such as foam plastics;

3) Supplementary Notes: You may have interest on CNC Plasma Cutting machine with strip cutting torches. For this please check product section of “Multi Purpose CG4000 Single Drive Strip CNC Plasma Flame Plate Cutting machine”.

3. Technical Parameters of CNC Plasma Plate Cutting Machine:

Below are technical parameters for this 4m gantry width Double Drive Gantry structure CNC Plasma Plate Cutting machine:

CG4000 Double Drive CNC Plasma Flame Plate Cutting Machine |

Parameters | Specification |

Cutting Rail Span | 4000 mm |

Valid Cutting Width | 3200 mm |

Cutting Rail Length | 15000 mm (At customer disposal) |

Valid Cutting Length | 13000 mm |

CNC Plasma Cutting Torch Quantity | 1 set (Suggestion) |

CNC Flame Cutting Torch Quantity | 2 sets |

Gantry Driving mode | Double Drive |

Gantry Driving Motor Power | 750 W x 2 |

Plasma Cutting Speed | 1000 ~ 3000 mm/min. (Servo Drive) |

Flame Cutting Speed | 100 ~ 1000 mm/min. (Servo Drive) |

Plasma Cutting Thickness | 0.3/1 mm ~ 22/25/35/45 mm |

Flame Cutting Thickness | 6 ~ 150 mm (Special made for 200mm) |

Cutting Precision | ±0.5mm/1000mm |

Cutting Gas | Oxygen, Acetylene/ Propane Compressed Air of 0.5~ 0.7 MPa. Gas flow:≥180L/min |