A. Usage and Applicable Workpieces of DX1535 Special Design Casting End Face Plate Milling Machine:

1. Purpose: This machine is for having end face milling on castings. In March of 2025, it will replace the current machine at customer facility:

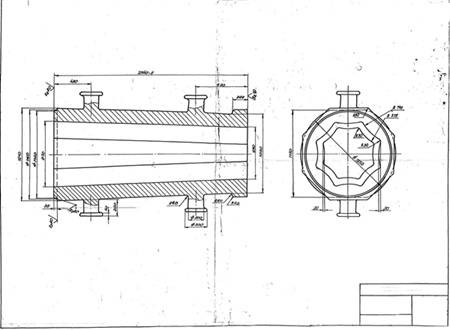

Existing machine running at customer workshop: (Fig.1)

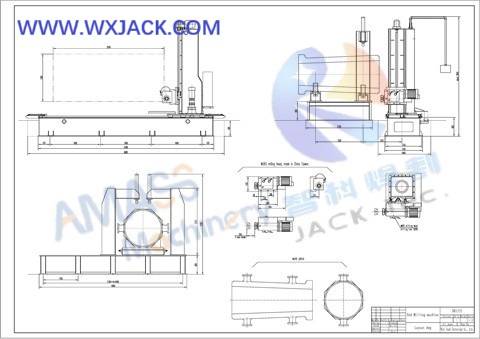

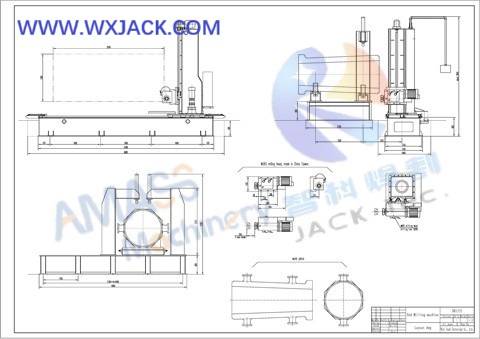

The erected and assembled DX1535 model special design machine at Wuxi JACK workshop, for performance testing, before painting: (Fig.2)

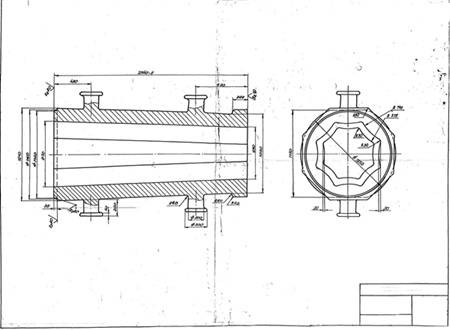

2. The Typical Specifications of Castings for DX1535 Special Design End Face Plate Milling Machine:

1) Length: 2540mm;

2) External Diameter: Φ1210mm;

3) Internal Diameter: Φ870mm;

4) Casting Wall Thickness: 170mm;

5) Weight: Up to 20 ~ 30 Tons;

6) Structure: With several vent holes along longitudinal body of casting parts;

7) Design sketch on customer workpiece casting: (Fig.3)

3. Function of DX1535 Steel Beam Facing End Plate Beams Machine:

1) Specification: Accordingly, Wuxi JACK proposed DX1535 model machine, with:

a) The max. end face milling area of 1500mm height by 3500mm width—Correspond with cross section size of casting workpiece;

b) Casting length can be 4,000mm long or longer;

2) End Face Milling Trace and Speed in Facing End Plate Beams Machine:

a) With 2 pieces of renowned brand A.C. inverters in electric system, Wuxi JACK machine has capability of X axis (Horizontal direction) and Y axis (Vertical direction) simultaneously milling, thus delivering slant trace milling, in the stepless adjustable cutting velocity of 100 ~ 800 mm/min.:

b) 2 pieces of A.C. inverter, for controlling on X axis motor (3kW) and Y axis motor (2.2kW) respectively: (Fig.4)

c) 2 pieces of milling speed digital display and grey color turning knob, on operating of the machine: (Fig.5)

4. Operation on DX1535 Steel Beam End Face Plate Milling Machine:

1) Milling Head: A piece of 11kW high power Taiwan produced E-LONG brand MU-6S model milling head acts as core working unit of the machine;

2) Maintaining Lowest Level Variable Cost of Consumables:

a) The consumables are D320 cutterhead and cutting blades;

b) These consumables are international universal standard types and models. So, customer (Based in East Europe) of the DX1535 Steel Beam End Face Milling Machine can easily source these consumables conveniently in their local market;

c) Besides, thanks to delicate design and top grade craftsmanship of the DX1535 model machine, and if maintained properly by customer technician, replacing frequency of machine consumables can be kept at the minimum level, thus greatly reducing daily running cost;

3) Convenient Replace Way on Milling Blade in DX1535 Casting End Face Plate Milling Machine:

a) In customer current machine, the blades are brazed onto cutterhead, and need to be cut off when worn and for replace. Such practice is old fashioned of 20 years ago;

b) Comparatively, in Wuxi JACK developed DX1535 model machine, this is in the easy way of “push and snap”, that just snap blades into milling head with click, and take out it with dedicated tool:

c) Old fashioned brazed blades onto cutterhead at customer existing machine: (Fig.6)

d) New type of cutterhead in Wuxi JACK Facing End Plate Beams Machine: (Fig.7)

e) Cutting blades supplied with cutterhead of Wuxi JACK machine: (Fig.8)

4) Lubrication on Linear Guiderails and Moving Parts:

a) This is important for getting proper service on machine, so as to promise its long term high standard running;

b) In Wuxi JACK conventional Steel Beam End Face Milling Machine, lubrication is semi-automatic, that operator press on lubricating pump in regular interval;

c) In this DX1535 special made machine, lubrication is fully automatic, thus relieving operators from low value added job:

d) Semi-automatic lubricating unit in conventional models of machine: (Fig.9)

e) Fully automatic lubricating unit in DX1535 Special Design End Face Plate Milling Machine: (Fig.10)

B. Overall Structure of DX1535 Special Design Casting End Face Milling Machine:

This is finalized design structure of DX1535, after 2 months discussion between customer and Wuxi JACK engineers: (Fig.11)

1. Mechanical Main Frame: Same as conventional model Steel Beam End Face Milling Machine, primary mechanical body of DX1535 is composed of:

1) Horizontal bed, laying in foundation of the machine at customer workshop;

2) Upright column, assembled onto the horizontal bed, in perpendicular;

Obviously Bigger Size: The overall dimension of mechanical frame: Horizontal bed and upright column is 30% larger than counterpart model of conventional products. For example, the horizontal bed has sizes of: 6800mm length, 600mm height, 1660mm depth. The overall height of machine is 3840mm. Operator platform is fixed at bottom of the uptight column;

2. Workpiece Fixing Platform of DX1535 Casting End Face Milling Machine:

1) With dimension of 4300mm length, 2200mm width, 600mm height, separately from mechanical main frame of the machine;

2) Casting Holding: There are 2 pieces of V shape bracket on this platform, perfectly accommodating on appearance of hexagonal casting;

3) Casting Press: 2 pieces of square frame with hydraulic drive pressing rod, composing the complete group of casting fixing unit:

4) Working parts clamping group unit of DX1535 model Special Design End Face Plate Milling Machine: (Fig.12)

3. Hydraulic Pump Station of DX1535 Casting End Face Plate Milling Machine:

1) Position: This is the 3rd piece of individually laid function unit of machine, following main frame and platform, sourced from Chinese 1st class professional company;

2) Role: It is put alongside mechanical main frame of the machine, supplying driving source on casting secure during face milling operation:

3) White color hydraulic pump station, hydraulic motor, electromagnetic valves of DX1535: (Fig.13)

4. Electric Control Board is fixed at lateral side of upright column, lessening occupation area of machine;

5. Heavy duty Precise Linear Guiderails of Wuxi JACK Steel Beam Facing End Plate Beams Machine:

1) Usage: Being assembled onto horizontal bed and upright column, instead of welded onto body as in other suppliers practice in market with ordinary section steel type guiderail, this function unit is for guiding movement of milling head along horizontal and vertical direction, during milling operation and rapid location;

2) Significance: This component is of vital importance on guaranteeing stable and superior milling effect of the machine;

3) Model: In all of Wuxi JACK DX series Steel Beam End Face Milling Machine, including this DX1535 special design, the guiderails are HIWIN brand HGH45 model. For this customer of DX1535, the guiderails are dust proof high level:

4) HIWN guiderail, assembled onto machine frame: (Fig.14)

C. Main Composition of DX1535 Special Design Casting Facing End Plate Beams Machine:

1. Milling Head: 11kW, Taiwan produced E-LONG brand, of MU-6S model. Advantage:

1) Higher power of milling head can have wider cutting with every stroke of milling. As effect, the finished milling face is more smooth and flat;

2) Deliver higher efficiency on milling operation;

3) The superior quality MU-6S milling head equipped with DX1535: (Fig.15)

2. Mechanical Horizontal Slides: Including work table, mechanical body, feeding drive and transmission system, horizontal guiderail guard cover;

3. Mechanical Upright Column: Including milling head motor drive moving carriage, column body, elevating drive and transmission mechanism, vertical guiderail guard cover;

4. Hydraulic System: Including hydraulic pump station, 5.5kW power hydraulic motor, oil hoses, electromagnetic valves;

5. Tool for Fitting Cutterhead Blade: Φ320mm standard facing blade bed (Cutterhead), fitting tool, etc.;

6. Electric Control System and Operating Panel: With 2 pieces of internationally famous A.C. inverter; Control relay and contactors--- All with dust proof design.

D. Technical Specialty of DX1535 Steel Beam End Face Plate Milling Machine:

On the basis of conventional DX series BOX H Steel Beam End Face Milling Machine, Wuxi JACK engineering team develops this special made DX1535 machine mainly on the aspects of:

1. Enlarged overall dimension, of 130%+ original size of counterpart model mechanical main frame, giving the equipment a more solid and strong operating base;

2. Higher power of milling head with more advanced configuration, from HD750 model 7.5kW made in Chinese mainland, to MU-6S model 11kW made in Chinese Taiwan;

3. Add on strong base of casting laying platform (Made of high steel carbon steel) and 2 pieces of V brackets, specifically for laying casting workpiece;

4. Special Design Square Frame Casting Clamping Group, composed of 2 pieces of hydraulic drive brackets, fixed onto platform;

5. Top Grade Dust proof level of all function units, raised from medium level (Suitable for majority use of the BOX H Steel Beam End Face Plate Milling Machine), to top level for this customer of Casting Foundry;

6. More user friendly arrangement: Raise automation level of machine, making it as safe and automatic as possible; Create more friendly operating environment, such as lighting lamp right above milling head.

E. Technical Parameters of DX1535 Special Design Steel Beam End Face Milling Machine:

№ | Parameter | DX1535 | Note |

1 | Max. Cross Section of Workpiece H×W | 1500×3500 mm | Vertical stroke is 1500mm; Horizontal stroke is 3500mm |

2 | Horizontal End Face Milling Speed | 100~800 mm/min. | Mitsubishi or Schneider A.C. Inverter adjust the speed |

3 | Horizontal Slides Idle Speed | 1200 mm/min. |

|

4 | Milling Head Vertical Speed | 100~800 mm/min. | Mitsubishi or Schneider A.C. Inverter adjust the speed |

5 | Horizontal Feeding Motor Power | 2.2 kW | IP54 protection level |

6 | Vertical Motor Power | 3.0 kW | IP54 protection level |

7 | Milling Head Motor Power | 11 kW | Chinese Taiwan MU6S type |

8 | Spindle rpm of Facing Head | 75~505 rpm. | 6 sections, adjust by hand wheel |

9 | Angle Range of Face Milling Head | no | Can’t adjust tilting angle |

10 | Diameter of Face Milling Blade Cutter | φ 160 ~315 mm |

|

11 | Travel Stroke of Milling Head Spindle | L=250 mm |

|

12 | Hydraulic Clamp Working Table | One set 2 pcs |

|

13 | Hydraulic Station Power | 3.0 kW | Independent sealing station, dust proof, with air filter |

14 | Hydraulic Station Max. Pressure | 12 MPa | Rated Pressure: 8 MPa |

15 | Worker Stand Working Table | One set | Hydraulic drive |

16 | Horizontal Move Cable Input | Drag chain |

|

17 | Milling Head Guiderail on Horizontal Bed and Upright Column | Double stages dust proof model Taiwan made HIWIN Heavy duty precise linear guideway; The guiderail on horizontal bed is protected with stainless steel cascading cover; The guiderail on upright column is protected with fire proof cloth organ type cover |

18 | Milling Tool with Machine Delivery | GMA250 | Diameter is Φ250mm |

19 | With automatic lubrication system | 2 sets |

|

20 | Electricity Power Specification | 380V, 50Hz, 3 Phase |

|

21 | Electric Control Cabinet and Buttons |

| Independent sealing dust proof; Dust proof model A.C. relay/ Contactors Pushbutton with dust proof cover |