The attached photos show a set of newly installed LHA55Z Gantry structure H Beam SAW Welding Machine at application site.

1. Applicating Characteristics of LHA55Z H Beam Gantry Welding Machine:

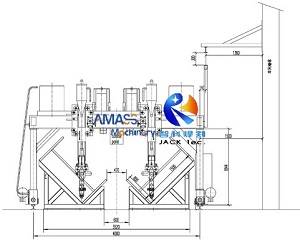

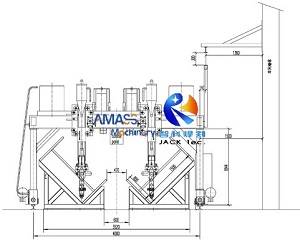

(Fig.1)

1) The LHA55Z is the largest model of automatic Gantry structure I Beam Welding Machine. It can weld H Beam with its web up to 2000mm. So, in the process of H Beam production, the Assembly and Tack welding machine matched with LHA55Z is Z20;

2) While for product section of LHA5Z Gantry structure I Beam Welding Machine, the mating Assembly machine is Z15 or Z18, depending on the max. web height to be made;

3) For LHA4Z Gantry structure H Beam SAW Welding Machine, it is Z15 (although LHA4Z and Z15 have different max. web height: LHA4Z I Beam Welding Machine is 1200mm, while Z15 H Beam Assembly Machine is 1500mm).

2. Notes for Day-to-Day Operations of Automatic LHAZ I Beam Gantry Welding Machine:

1) Welding mode in the LHAZ H Beam Gantry Welding Machine:

a) Submerged arc welding usually utilizes large current of 1000A, 1250A or 1500A (in CO2 tack welding, it is 350~ 500A), at 45° fillet position of H Beam: (Fig.2)

b) Unlike CO2 tack weld in Assembly machine, this SAW is not recommended to be performed manually. Which means, for LHAZ series I Beam Gantry Welding Machine, only automatic welding mode is available, no option of manual welding;

2) Welding Speed in LHAZ I Beam Gantry Welding Machine:

a) As introduced, welding speed is gantry travel speed. It is inverter control based on demanded welding technology, within the range of 0.24 ~ 2.4m/min: (Fig.3)

b) On the operating panel of the LHAZ Gantry structure I Beam Welding Machine, there is knob for its adjustment, and digital display unit for its showing in actual and real time manner;

3) Operator skill for LHAZ Gantry structure H Beam SAW Welding Machine:

a) With automatic welding in this LHAZ automated Gantry structure I Beam Welding Machine, its operator does not need to command superb welding skill and rich expertise as in the case of manual welding. However, he or she should grasp welding knowledge and gain welding experience of at least medium level;

b) To be specially, the capability of operator for LHAZ Gantry structure H Beam Submerged Arc Welding Machine:

i. Managing SAW welding process with SAW power supply in the I Beam Welding Machine;

ii. Judging SAW quality of the H Beam Submerged Arc Welding Machine;

iii. If ever welding defects happen, how to make ICA repair (Imminent Corrective Action) on the Gantry structure H Beam SAW Welding Machine;

c) For this reason, if a novice comes to the position of operating the LHAZ series H Beam Gantry Welding Machine, he or she needs to take part in the corresponding training and pass the skill test (qualified), before working on his or her own;

4) Integration of Outsourced units into LHAZ I Beam Gantry Welding Machine:

a) With numerous outsourcing units equipped in this H Beam Gantry Welding Machine,

i. Large welding current SAW power supply of two sets;

ii. SAW Flux recovery unit of two sets;

iii. SAW Wire feeder of two sets;

iv. SAW Arc tracing unit of two sets;

b) The linkage among the abovementioned outsourcing units, and with main equipment of the LHAZ I Beam Gantry Welding Machine, to make it into an integral system, is important for both producer and user of the automatic Gantry structure I Beam Welding Machine;

c) Specifically, in LHAZ H Beam Gantry Welding Machine:

i. On the one hand, each unit has its own console for manipulation;

ii. On the other hand, control system of this Gantry structure H Beam Submerged Arc Welding Machine integrates control of these units into its control circuit and feedback loop;

iii. And on the aspect of operation, operating panel of the LHAZ H Beam SAW Welding Machine has corresponding button or switch to manipulate each of the individual unit;

iv. Manuals of all these outsourcing units will be supplied to customer together with other technical documents, at the time of LHAZ H Beam Gantry Welding Machine delivery and acceptance.

3. Technical Parameters of LHA55Z H Beam Gantry Welding Machine:

Below are specifications of this LHA55Z center control High Precision I Beam Gantry Welding Machine:

LHA55Z Gantry structure I Beam Welding Machine |

Parameter | Specification | Note |

Operator Working Position | Center of Gantry, between 2 supporting racks |

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 | Can be special made |

H Beam Web Height (mm) | 200 ~ 2000 |

|

H Beam Web Thickness (mm) | 6 ~ 32 | Can be special made |

H Beam Length (mm) | 4000 ~ 15000 |

|

Gantry Span (mm) | 5500 |

|

Gantry Travel Rail Length (mm) | 18000 |

|