A. Customer Requirement on Special Traits of the SXBJ-12 Special Design Plate Edge Milling Machine:

1. Workpieces to be Beveled from SXBJ-12 Equipment for Beveling Sheet Metal Plate:

Customer needs to carry out machining on the working parts of various material sheet metal plate with specifications of:

1) Thickness is in the range of 10 mm ~ 200 mm;

2) The corresponding blunting size on finished groove, should be in the scope of 1 mm ~ 10 mm;

3) The completed angles of groove can be 10º/ 20º/ 25º/ 30º/ 40º/ 45º/ 50º/ 55º;

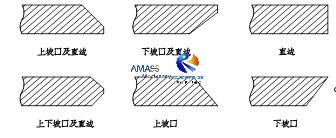

4) The actual finished 45º groove on a piece of workpiece steel plate, machined from Wuxi JACK Edge Milling Machine: (Fig.1)

2. Overall Capability of the SXBJ-12 Special Design Plate Edge Milling Machine:

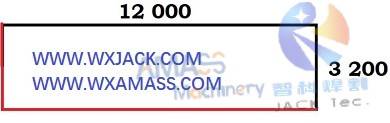

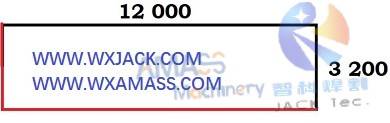

1) The working part main size can be up to 12000 mm length x 3200mm width;

2) The effective size in this machine for machining is: 6000 mm length x 3200 mm width;

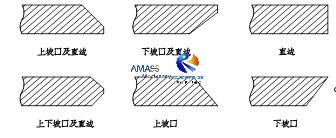

3) The form of finished grooves: I/ V/ X/ Y/ J chamfers: (Fig.2)

3. Operating Actions in the SXBJ-12 Sheet Metal Plate End Milling Machine:

1) Initially, customer asked for the max. valid working stroke in this Equipment for Beveling Sheet Metal is 6000mm;

2) But the part max length is up to 12000mm. The customer is going to replace the working parts for machining all part length;

3) So, customer determines the max. valid working stroke to be 12000mm in the machine;

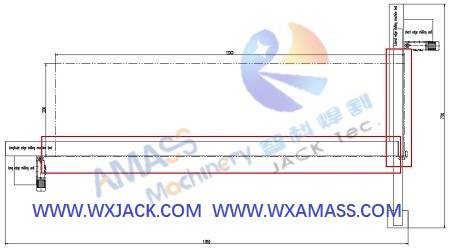

4) And, this special design machine should be able to have edge milling operation, on both horizontal and transverse sides of sheet metal simultaneously: (Fig.3)

B. Mechanical Structure of the SXBJ-12 Special Design Plate End Milling Machine:

1. Overall Constructure of the SXBJ-12 Equipment for Beveling Sheet Metal:

1) Correspondingly, mechanical structure of this Equipment for Beveling Sheet Metal is different from general purpose Edge Milling Machine:

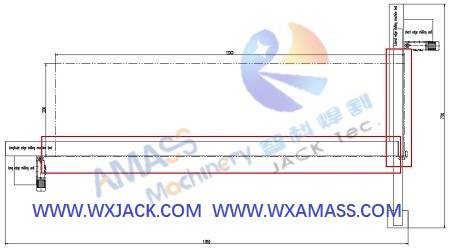

2) Instead of monogram linear main body, if you check this machine from vertical view, it is in the form of L shape, with a long side and short side working table, which are perpendicular with each other:

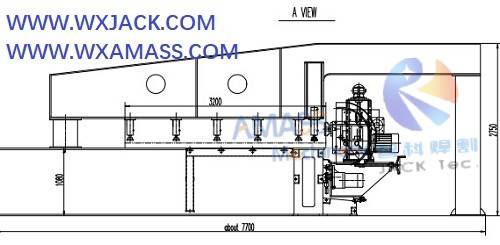

3) Vertical view on design of the Wuxi JACK SXBJ-12 special design machine: (Fig.4)

2. The skeleton of this SXBJ-12 Special Design Plate Edge Milling Machine:

As can be observed from the above design drawing:

1) This Equipment for Beveling Sheet Metal has one group of 14m length lengthways working table, for delivering 12m stroke machining;

2) And has one group of 7.7m length transverse working table, for delivering 3.2m stroke machining;

3) Both the horizontal and lateral side of the machine are installed with 1 set of 7.5kw milling head and its driving carriage respectively.

C. Technical Description on the SXBJ-12 Equipment for Beveling Sheet Metal Plate:

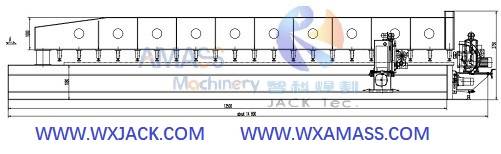

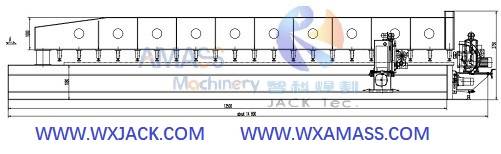

1. Front View on the SXBJ-12: (Fig.5)

1) The height of both horizontal and transverse working tables is 1080mm, suitable for any adult operator conveniently operation;

2) Movement of the milling head is driven with A.C. motor, with its moving speed managed by means of A.C. inverter, and displayed in digital form;

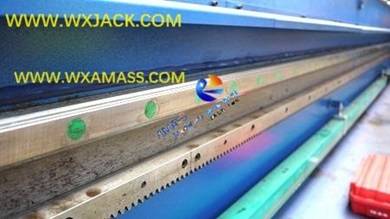

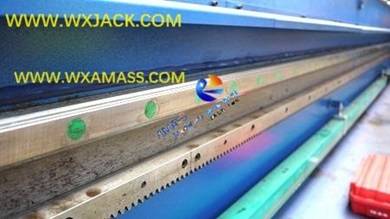

3) Guided with heavy duty high precision linear guiderail in Wuxi JACK XBJ and SXBJ series Plate Edge Milling Machine: (Fig.6)

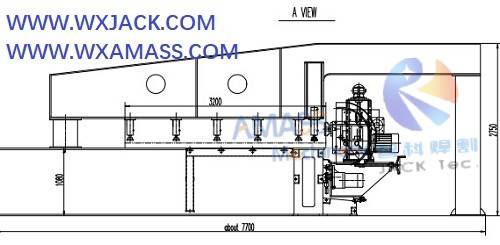

2. Side View on the SXBJ-12 mechanical main frame: (Fig.7)

Shown in the above design sketch:

1) The most distinguished feature of this set of machine, lies in its installation of a piece of 7.5kW milling head at lateral side, in other words, short side;

2) Such structure and configuration enable the machine to have edge milling on both adjacent sides of working parts sheet metal at the same time;

3) Advantage of the Such Structure and Configuration for the Plate Edge Milling Machine:

In this way, the entire edge milling grooving productivity can be raised more than double folds, because:

a) Not only edge milling cycle time is reduced to around 50% of original level;

b) But also logistics work of rotating steel plate 90°, unloading it from the machine, moving it a certain distance, and then loading it into the machine again, can be removed;

3. Operating the SXBJ-12 Special Design Plate End Milling Machine:

1) Also demonstrated in the above illustration, there is a group of 3.2m extension grounding racks, installed ahead of the both sides working table of the machine, so as to pushing in and pulling out the sheet metal plate safely and easily:

2) Loading the raw material steel plate into Wuxi JACK Edge Milling Machine by way of grounding brackets: (Fig.8)

3) Besides conventional straight side grooving, this special design machine is also equipped with arc shape grooving function: (Fig.9)

4) The round shape arc style groove cut with special cutter head: (Fig.10)

D. Technical Parameters of the SXBJ-12 Sheet Metal Plate Edge Milling Machine:

1. Milling Center:

1) As one group of integral working center;

2) The machine has max. edge milling of 12m length;

3) The lateral machine has max. edge milling of 3.2m;

2. The Max. Allowable Sheet Metal Size for the Equipment for Beveling Sheet Metal:

1) It can be up to: Has thickness 200mm x Width 3200 mm x Length 12000mm;

2) These working parts sheet metal plates can be edge milled with two perpendicular sides at the same time;

1) Two sets of the machines are installed with one piece of milling head respectively;

2) These 2 pieces of milling heads are made in Chinese Taiwan, with 7.5KW power, MU6S type:

3) The 7.5kW Taiwan made milling head equipped in Wuxi JACK machine: (Fig.11)

4) The milling head shaft rotate speed is 75-505 rpm., 6 section adjusted by manual operation;

5) For the two pieces of milling units, milling angle is in the range of 0° to 55°, for completing top side milling job in the machine;

6) Each of the milling head has milling tools with diameter of Φ200mm;

4. Hydraulic System of the SXBJ-12 Edge Milling Machine:

1) Hydraulic clamps press the workpiece steel plate when milling the plate: (Fig.12)

2) The total quantity of hydraulic clamp is 21+5 pieces, and easy to press the sheet metal plate;

3) A group of 2 sets of hydraulic drive workpiece pushing and pulling system;

4) The hydraulic station power is 5.5KW; And working press is 4MPa;

5) The up rail on mechanical main bed is Taiwan HINWIN ball linear guideway.