1. Outline on HB1500 Semi-Automatic Welding H Beam Production Line:

1) Main Equipment:

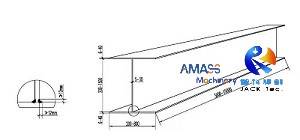

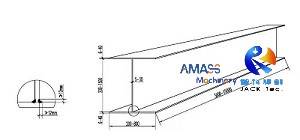

Core Equipment: The attached first photo reflects on the three core H Beam Production Machine composing the HB1500 line for semi-automatically H Beam production:

a) The Z15 H Beam Assembly Machine;

b) The LHA H Beam Gantry Welding Machine;

c) The HYJ-40 mechanical H Beam Straightening Machine;

2) Usage of HB1500 Line for Welding H Beam Semi-Automatic Production:

a) This is a cost effective solution for steel structure customers, on the aspect of making small and medium size welded H Beam: (Fig.1)

b) Features: These semi-automatic H Beam Production Machine has relative lower investment compared with fully automatic line for H Beam production;

3) Characteristic of Semi-Automatic Welding H Beam Production Line:

a) The automatic line is an internal streamline connecting all the work stations of H Beam Production Machine, by means of Steel Structure Flipping Equipment and Overturning Rack. Workpiece flows in this line without external intervention;

b) Comparatively, H Beam Production Machine in semi-automatic line are individual points. The movement of workpiece among these machine tools and equipment are by means of exterior utilities, such as traveling crane.

2. Financial Analysis on Cost Effectiveness of Semi-Automatic Welding H Beam Production Line:

There are three cost reduction aspect in semi-automatic line, compared with fully automatic Line:

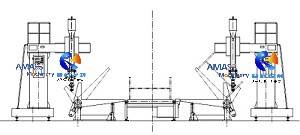

1) Removal of Steel Structure Flipping Equipment:

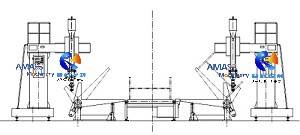

One is eliminating on Steel Structure Flipping Equipment applied in Automatic H Beam Production Line: (Fig.2)

2) H Beam Gantry Welding Machine:

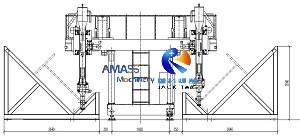

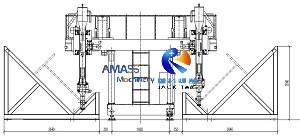

a) Based on its machine frame structure, this machine for H Beam submerged arc welding has three options of:

1) LHC series Column trolly moving structure;

2) LHT series open structure T frame;

3) LHA series Gantry moving structure

Design sketches on 3 major types of H Beam Gantry Welding Machine: (Fig.3)

b) Of which the only applicable model for Automatic H Beam Production Line is LHC;

c) For Semi Automatic H Beam Production Line:

LHT and LHA series are applicable, because:

1) All these are determined by match condition between process technology in Automatic H Beam Production Line, and structure of the H Beam Gantry Welding Machine;

2) The other reason is due to the relative lower welding velocity of H Beam SAW welding, which is around 200 ~ 1200 mm/min.), compared with straightening speed of H Beam Straightening Machine (Around 9000 mm/min.). For this reason, in typical automatic Welding H Beam Production Line, it needs four sets of LHC model machine for fulfilling 4 pieces of SAW welding seam;

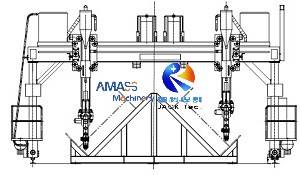

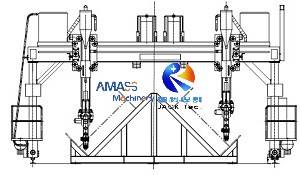

3) Comparatively, in semi-automatic H Beam Production Line, only one set of either LHA or LHT H Beam Gantry Welding Machine is necessary. The attached fourth photo is a set of T frame LHT model equipment, being installed at Wuxi JACK facility;

d) Summing up, machine investment budget in semi-automatic H Beam Production Line is around 40%~ 50% less than that of automatic Line;

3) Saved Land Occupation in Semi-Automatic H Beam Production Line:

a) Besides relative less machine investment budget, another benefit of semi-automatic line is, with removal of the Steel Structure Flipping Equipment including travel cart and overturning units, certain area of workshop floor is spared;

b) Only land area for locating the three core H Beam Production Machine (H Beam Assembly / Welding / Straightening) are necessary;

c) In this sense, the Semi-Automatic welding H Beam Production Line has characteristic of flexible and compact layout;

4) In summary, semi-automatic line has high index of Performance Price Ratio for customers making welding H Beam.

3. Technical Parameters of HB1500 Semi Automatic H Beam Production Line:

Model | HB1500 Semi Automatic Welding H Beam Production Line |

Max. H Beam Web Width (mm) | 1500 |

H Beam Web Thickness (mm) | 6 ∽ 32 |

H Beam Flange Width (mm) | 200 ∽ 800 |

H Beam Flange Thickness (mm) | 6 ∽ 40 |

H Beam Length (mm) | 4000 ∽ 12000 |

Max. H Beam Weight | 20 Ton. |

Machine for H Beam Assembly | Z15 |

First Stage Welding Technique | CO2 Tack Welding |

Machine for H Beam Welding | LHA or LHT |

Finished Welding Technique | 45° Submerged Arc Welding |

Machine for H Beam Flange Straightening | HYJ-40 |

Transfer of H Beam workpiece among stations | By means of Travel crane by operator |