Subject of this Blog on Integral Function 3 in 1 H Beam Welding Machine:

1) Business Background: 3 in 1 H Beam Fabrication Machine has been put into market for over decade since the year of 2009, and witnessed rapid growth ever since, in sub-division of light duty and medium duty welding H Beam/ I Beam/T Beam production;

2) Market Boom: Recent years also see rapid demand on small size 3 in 1 H Beam Fabrication Machine. Which usually has specifications of:

- H Beam flange width and web height not up to 500mm;

- H Beam flange and web thickness in the scope of 3mm ~ 12mm;

3) This Short Article will focus on below Topics of 3 in 1 H Beam Assembly Welding Straightening Machine:

a) Comparison between standard size and ultralight H Beam from 3 in 1 H Beam Fabrication Machine;

b) The Application of Light duty and Ultralight duty H Beam, and its Integral Function 3 in 1 H Beam Welding Machine;

c) Wuxi JACK’s Action on Upgrade of Automatic 3 in 1 H Beam Production Machine

A. Comparison between Standard Size and Ultralight H Beam from 3 in 1 H Beam Fabrication Machine:

1. The Other Common Used Name of 3 in 1 H Beam Fabrication Machine:

1) 3 in 1 H Beam Assembly Welding Straightening Machine;

2) Automatic 3 in 1 H Beam Production Machine;

3) Pull Through H Beam Welder;

4) Integral function 3 in 1 H Beam Welding Machine, etc.;

2. H Beam Specifications Comparison between "Nomal" Size and Small Model 3 in 1 H Beam Assembly Welding Straightening Machine:

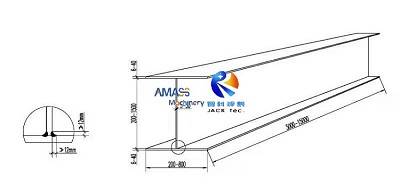

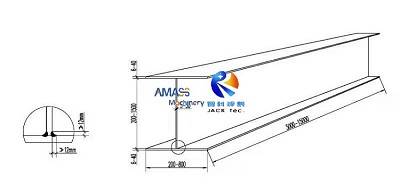

Please check below two sketches on:

Illustration of finished welding H Beam/ I Beam made with Automatic 3 in 1 H Beam Production Machine: (Fig.1)

1) For a piece of welding H Beam/ I Beam, the critical sizes are:

a) Web height H;

b) flange width B;

c) Web thickness A;

d) flange thickness T;

2) Conventional Dimensions of H Beam to be Produced from H Beam Production Machine:

a) Max. Width of H Beam Flange: 800mm;

b) Max. height of H Beam Web: 3 grades of 1,500/1,800/ 2,000mm, which corresponds with three standard models of integral function 3 in 1 H Beam Welding Machine ZHJ15/ 18/ 20;

c) The most often selected model is ZHJ15;

d) Max. Thickness of H Beam web: 32mm;

e) Max. Thickness of H Beam flange: 40mm;

3) Specifications of H Beam to be Produced from Light duty Integral Function 3 in 1 H Beam Welding Machine:

It is around half of the standard web height and flange width; One third of flange and web thickness:

a) The max. web height: About 750mm ~ 1,000mm;

b) Average flange width 150mm~ 200mm;

c) flange and web thickness: Only about 10~12mm, which is close to bottom limit of workpiece produced with standard 3 in 1 H Beam Assembly Welding Straightening Machine.

B. The Application of Small Size H Beam and Its Integral Function 3 in 1 H Beam Welding Machine:

So, what is the sub-division application area of such light duty and ultra light duty H Beam/I Beam?

1. As we know, the standard sized welding H Beam produced with integral function 3 in 1 H Beam Welding Machine is usually used in steel structure constructions for building facility/ stadium, etc.;

2. While for much smaller size H Beam, these structure members are often used in Civil Building/ Shipbuilding, etc. Which, has seen rapid market demand and huge market potential in recent years;

3. Wuxi JACK Breakthrough on Development of Integral Function 3 in 1 H Beam Welding Machine:

In July 2021, a set of ZHJ5010 Integral Function 3 in 1 H Beam Welding Machine (3 in 1 H Beam Fabrication Machine, for building H Beam with:

1) Flange width up to 500mm;

2) Web height up to 1000mm;

Was shipped from Wuxi JACK to an overseas customer;

3) This is the 3rd sets of such tailor made light duty 3 in 1 H Beam Assembly Welding Straightening Machine delivered to overseas market by Wuxi JACK by the middle of 2021;

4) The other two sets of such smaller size tailor made 3 in 1 Pull Through H Beam Welder were made for customer in Ethiopia and Southeast respectively.

C. Wuxi JACK's Action on Upgrade of Automatic 3 in 1 H Beam Production Machine:

1. Design Upgrade on Tailor Made Special Size 3 in 1 H Beam Fabrication Machine:

1) Challenge: As a Chinese saying goes, “Quantitative change brings along qualitative change ”. For design and manufacture of integral function 3 in 1 H Beam Welding Machine, the reduction in its workpiece does not equal to simple decrease on machine size;

2) Actions Taken: The stress calculation/ structure verification/ welding technique need to be made start from scratch again, based on experience on standard models of 3 in 1 H Beam Fabrication Machine (3 in 1 Pull Through H Beam Welder);

3) Value Chain: With the same structure and working principle as standard models, these special made Automatic 3 in 1 H Beam Production Machine have been redesigned/ manufactured and validated, making it a perfect product for customer;

2. Examples on Upgrading Design Integral Function 3 in 1 H Beam Welding Machine:

1) Welding Mode in ZHJ5010 Model 3 in 1 H Beam Assembly Welding Straightening Machine:

a) Adopt CO2 MIG/MAG welding to substitute the original SAW (Submerged arc welding) in welding mode of the Automatic 3 in 1 H Beam Production Machine;

b) When Use SAW: As we know, SAW is applicable in welding of medium and large thickness of steel structure workpieces, thanks to its large current/ Big welding cover and deep penetration. So, it takes majority position in integral function 3 in 1 H Beam Welding Machine;

c) When Use CO2: While for H Beam flange thickness less than 10mm, even 5~6mm, CO2 MIG/MAG is much better in producing light duty and ultra light duty workpiece;

2) Straightening Capacity for H Beam Flange in ZHJ5010 3 in 1 H Beam Fabrication Machine:

a) As we know, in standard size integral function 3 in 1 H Beam Welding Machine, there is a rule of thumb in the relationship between flange width and thickness that can be straightened;

b) With the size diminish in flange, these data need to be analyzed and validate again. Anyway, the smaller the size, the more difficult to be straightened.

D. Summary on Integral Function 3 in 1 H Beam Welding Machine:

1) As the first producer who put the mature and good quality Integral function 3 in 1 H Beam Welding Machine (3 in 1 H Beam Fabrication Machine) into market in the year of 2009, Wuxi JACK always keep leading edge in this sub-division area;

2) Over the past decades, we have produced and delivered over ten hundreds of such 3 in 1 Pull Through H Beam Welder of various model and structure, including standard ones and special made ones;

3) We always take the first brunt in new challenge and development. For more detail, please check product family of 3 in 1 H Beam Assembly Welding Straightening Machine;

4) As a well established producer for welding and cutting equipment, Wuxi JACK also produces other quality products, for example, Welding Manipulators, Plate Butt Joining Machine, etc. Please check.