1) The loading capacity of 160 Ton and above, in the standard series that can be up to 1000 Ton, for special made at present is max. 2000 Ton, are all classified as Heavy duty Weld Rolling Bed:

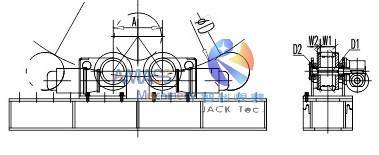

Design sketch: (Fig.1)

2) This is where the HLK series adjustable by bolt Welding Rotator stands out from the other two types: HGZ series Self Adjustable and HGZ series Leadscrew Adjustable: That only the HLK series Bolt Adjust Welding Rotator can fulfil the challenging task of welding on heavy tonnage workpiece.

To achieve the task of heavy loading capacity in the Weld Rolling Bed, two components of these heavy duty large welding machine tool play critical role in it:

a) It is fasteners during assembling process on a set of standard HLK models adjusting with bolt, which subject to great force;

b) All these mounting bolts are made of high strength steel, making sufficient intensity of the weld machine tool;

c) The size of mounting bolts in a set of bolt adjusting Welding Turning Roller varies, based on rated loading tonnage of the Welding Rotator: Larger models are secured with bigger size of bolts;

d) Under normal condition and proper maintenance, these mounting bolts have the same length of service life as the welding equipment itself;

a) Same as the “HGZ Heavy duty Standard Self Adjustable Welding Rotator for Tank”, all the Welding Turning Roller with tonnage higher than 160 Ton are equipped with fully metallic roller:

Wuxi JACK fully metallic turning rollers: (Fig.2)

b) To be specific, these Welding Turning Roller are made of alloy nodular cast iron, with good heat resistant performance.

a) As discussed in the previous product sections, Hydraulic Jack up Weld Rolling Bed, and or Anti Drifting Welding Turning Roller, are all originated from the 60~600 Ton loading capacity models. Loading tonnage in majority of these Anti Drifting Welding Rotator coincide with that of the heavy duty models equipment;

b) These Anti Drifting Welding Turning Roller are often used in national level big projects, where the best degree of precision and quality is required. For example, in China, Oil and Gas Transmission Pipeline from West to East;

As an emerging industry, the build up of wind tower involves utilization of large amounts of these heavy duty welding machine tools equipment;

As a kind of special requirement and process technology container, welding of oil tank involves application of high quality sophisticated heavy duty models, especially the Anti Drifting Welding Rotator.

1) Some of these Large Weld Rolling Bed are installed at outdoors working environment. Give protection on it against infiltration of rain, wind, etc. is of primary importance;

2) Workpiece operated on the large heavy duty models welding equipment is generally big and heavy. Before loading it onto the Welding Rotator, make sure the smooth exterior surface of barrel body, no sharp particles retained;

3) Take great care on no bumping happened in the process of workpiece loaded onto the heavy duty equipment.

HLK Series Heavy duty Welding Rotator Adjusting with Bolt | ||||||||

Model | HLK160 | HLK250 | HLK400 | HLK500 | HLK630 | HLK800 | HLK1000 | |

Max. loading of the Weld Rolling Bed (Ton) | 160 | 250 | 400 | 500 | 630 | 800 | 1000 | |

Workpiece | D (mm) | ø1000 ~6000 | ø1000 ~7500 | ø1000 ~7500 | ø1000 ~8000 | ø1000 ~8500 | ø1500 ~9000 | ø1500 ~10000 |

PU roller (mm) | D1 | Metallic rollers are used for large tonnage roller bed | ||||||

W1 | ||||||||

Metallic roller (mm) | D2 | 620 | 700 | 800 | 800 | 850 | 1000 | 1000 |

W2 | 220 | 260 | 300 | 300 | 350 | 350 | 350 | |

Linear speed of the Welding Turning Roller (m/h) | 6 ~ 60 | |||||||

Motor Power of the Welding Rotator (kW) | 2×4 | 2×5.5 | 2×5.5 | 2×5.5 | 2×7.5 | 2×7.5 | 2×11 | |

content is empty!