1. Usage and Application of I H Beam Straightening Machine:

1) When Need: In the process technology route of welding H Beam Production Line, H Beam flange tilt up after the 3rd station of submerged arc welding. This flange deformation is caused from heat input in the SAW process, and should be removed with corresponding I H Beam Straightening Equipment;

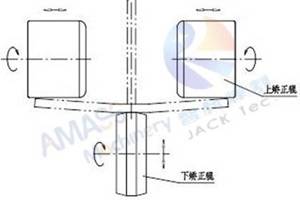

2) Straightening Principle: Both sides of the H Beam flange will be downward pressed firmly with 2 pieces of rolling rollers from its top side. Meanwhile, bottom side of the flange is supported/ propped up and transmitted with a larger rolling roller:

“3 points subject to force” principle in I H Beam Straightening Machine: (Fig.1)

The above 3 pieces of straightening rollers form up straightening cavity of the machine;

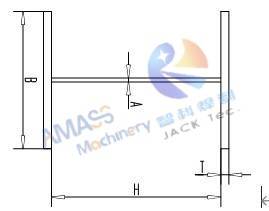

3) Operating Way: Driven with A.C. motors of the input and output conveyors, H Beam goes through straightening cavity of the machine in constant speed, got straightened in the process:

H Beam being straightened out of Wuxi JACK YTJ80 H Beam Hydraulic Straightening Machine: (Fig.2)

2. Classification on Wuxi JACK I H Beam Straightening Equipment:

Based on orientation and position of H Beam during straightening operation, the machine has two general types of:

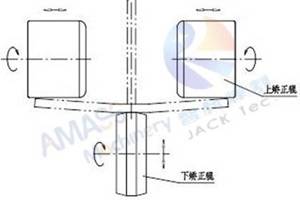

1) Mainstream: Vertical H Beam Straightening Machine:

In this structure, H Beam “stands” in upright position on conveyors of the machine during straightening: (Fig.3)

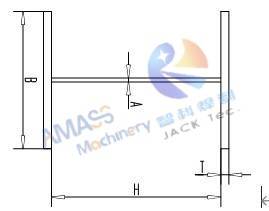

2) Small Group Use: I H Beam Horizontal Straightening Machine:

In this structure, H Beam “lies” flat on conveyors of the machine during straightening: (Fig.4)

Over 90% of flange purpose I H Beam Straightening Machine in practical use is with H Beam standing up position. It is default structure of the machine.

3. 2 Forms of Straightening Drive in I H Beam Straightening Machine:

1) HYJ Series Motor Drive I H Beam Straightening Equipment: (Fig.5)

Drive Form: 2 sets of A.C. motors in straightening cavity of the machine;

Straightening Capacity: This series is standard configured machine in conventional H Beam production line, for straightening on:

a) H Beam flange with thickness up to 40mm;

b) H Beam is fabricated from Chinese grade Q235 carbon steel, tensile strength in the range of 370~510MPa;

2) YTJ Series I H Beam Hydraulic Straightening Machine:

Drive Form: 2 pieces of oil cylinders in straightening cavity of the machine;

Straightening Capacity: This series is applied on heavy workpieces, for straightening on:

a) H Beam flange thickness up to 40~ 80mm;

b) H Beam is assembled and welded from Chinese grade Q345 carbon steel, tensile strength in the scope of 510~600MPa;

Structure of YTJ40/50 is different from YTJ60/80, considering straightening effect on H Beam:

a) Wuxi JACK YTJ50 I H Beam Hydraulic Straightening Machine: (Fig.6)

b) Wuxi JACK YTJ80 I H Beam Hydraulic Straightening Machine: (Fig.7)

3) WJ Series Hydraulic H Beam Horizontal Straightening Machine: (Fig.8)

a) Straightening Capacity: The max. H Beam flange thickness has 2 grades: 25/ 40mm;

b) H Beam is assembled and welded from Chinese grade Q235 carbon steel, tensile strength 370~510MPa.

4. Lengthways Direction Hydraulic H Beam Horizontal Press Straightening Machine:

1) Specialty: This niche group HJ series steel BOX H Beam Horizontal Press Straightening Machine is featured product of Wuxi JACK. Very few Chinese companies have technical strength and experience to design and produce it;

2) Usage: This machine straightens on the integral piece of H Beam (Or long other steel structure workpieces) along its lengthwise direction, similar to ASM series Angle Steel Straightening Machine:

Longitudinal winded H Beam for Horizontal Press Straightening Machine: (Fig.9)

3) Application: Besides H Beam, other long length “slim” steel structure workpieces, like BOX Beam/ Pipe/ Section Steel... can all be processed in high efficiency with this niche group of the straightening equipment:

4) Wuxi JACK HJ300 steel structure Horizontal Press Straightening Machine works on BOX Beam: (Fig.10)

5) Wuxi JACK exported to Russia HJ300 steel Beam Horizontal Press Straightening Machine: (Fig.10)

5. Model List on Technical Specifications of Wuxi JACK I H Beam Straightening Machine:

Note: Detailed introduction on each model of the equipment please refer to corresponding product section:

List on I H Beam Straightening Machine |

For Straightening Deform of | H Beam Position | Driving Mode | Model | Specification |

H Beam Flange Deform | Standing Up | Mechanical for Q235, tensile strength 370~510MPa | HYJ-40 | Flange thickness 40mm HYJ-40 and HYJ-800 have different straightening speed. |

HYJ-800 |

Hydraulic for Q345, tensile strength 510~600MPa | YTJ-40 | Flange thickness 40mm |

YTJ-50 | Flange thickness 50mm |

YTJ-60 | Flange thickness 60mm |

YTJ-80 | Flange thickness 80mm |

Lying Down | Hydraulic | WJ25 | Flange thickness 25mm |

WJ40 | Flange thickness 40mm |

H Beam Length Direction Deform | Based on cross section shape and size | Hydraulic | HJ20 | 20Ton Straighten Force |

HJ100 | 100Ton Straighten Force |

HJ200 | 200Ton Straighten Force |

HJ300 | 300Ton Straighten Force |