Background of This Blog on Wuxi JACK Sheet Metal Edge Milling Machine:

1) On Oct.10th, 2021, a set of SXBJ-3 double heads Plate Edge Milling Machine was made shipment by Wuxi JACK to a middle European customer;

2) This short blog will give brief introduction on this set of double heads Plate End Milling Machine;

3) Main Topics Covered in This Blog on Plate Edge Milling Equipment:

Capability of the SXBJ-3 Edge Milling Machine the Latest Delivered;

General Introduction on Plate Edge Milling Equipment;

Wuxi JACK Strength on Plate End Milling Machine

A. Capability of the SXBJ-3 Plate Edge Milling Machine the Latest Delivered:

1. Max. Edge Milling Stroke: This set of 3,000mm stroke sheet metal Plate Beveling Machine has ability of making welding groove on workpiece with max. 3,000mm length;

2. Main Configuration and Functions of Plate Edge Beveling Machine:

1) With two sets of 7.5kW milling heads equipped with the plate Edge Milling Machine, the workpiece can be edge beveled with top and bottom chamfers in one time stroke:

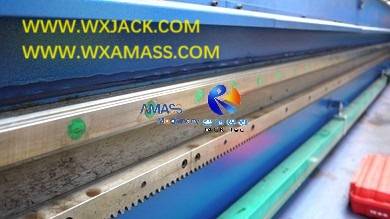

Working side of Wuxi JACK SXBJ-3 double heads Plate Edge Milling Machine: (Fig.1)

2) Straight/ slant/ blunt edges can be made on workpieces in this set of double heads plate End Milling Machine:

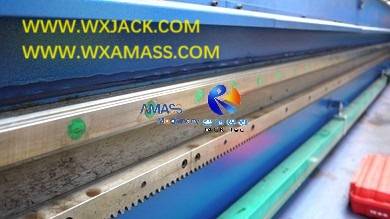

The milling head making lower edge beveling in Wuxi JACK SXBJ-3 double heads plate End Milling Machine: (Fig.2)

3. Wuxi JACK Exclusively Owned Hydraulic Drive Workpiece Loading System in Plate Edge Beveling Machine:

1) This set of SXBJ-3 sheet metal Edge Milling Machine has one set of hydraulic drive assisting loading/ unloading unit at its front side of supporting racks;

2) It is the exclusive configuration by Wuxi JACK;

3) With this powerful unit, the original toilful and risk job of material handling becomes safe, convenient and highly effective in the sheet metal Edge Milling Equipment:

Commissioning on hydraulic drive loading system of Plate Edge Milling Equipment at Wuxi JACK workshop: (Fig.3)

4) For its detail introduction, please check the product section of “Hydraulic Special Loading SXBJ-12 Double Heads Metal Plate Edge Milling Machine”.

B. General Introduction on Plate Edge Milling Equipment:

1. Main Functions of Plate End Milling Machine:

1) Nomination: Edge Milling Machine, the other names include End Milling Machine/ Edge Beveling Machine/ Plate Beveling Machine/ Plate Chamfering Machine, is used for making welding groove on metal plates into different kinds of bevels/ chamfers as below

Illustration on 6 main types of upper, lower and straight beveling from Plate Edge Milling Equipment: (Fig.4)

2. Working principle of Edge Milling Machine is to utilize high speed milling cutter along edge/ side of workpiece in the working speed of plate Sheet Metal Edge Milling Machine;

3. Category and Models of Sheet Metal Plate Beveling Machine:

1) There are series of specifications/ structures, and configuration of Edge Milling Machine to choose from, catering on wide range of demand on workpieces and design features:

2) The smallest stroke, or valid edge milling length is 3,000mm. The corresponding models of the Edge Milling Equipment is XBJ-3 (Single head configuration) / SXBJ-3 (Double heads configuration);

3) The longest stroke can be up to 18,000mm for standard gantry structure Plate Edge Milling Machine (SXBJ-18), and 23,000mm for special designed splitting type Edge Milling Equipment;

Wuxi JACK SXBJ-18 Double Heads Edge Milling Machine working at outdoors site of customer: (Fig.5)

4. Usage and Application of Plate Edge Milling Equipment:

1) Workpieces edge beveled with this Edge Milling Machine have better quality and productivity for the next step of welding process;

Finished bevel steel plate from Wuxi JACK End Milling Machine: (Fig.6)

2) Applied Industries: These Sheet Metal Edge Milling Machine are widely used in various manufacturing industries. For example: Steel Structure/ Construction Machinery/ Engineering Machinery/ Power Plant/ Chemical, Bridge/ Shipbuilding/ Port Machinery, etc.;

3) Edge Milling Machine usually works together with other equipment, such as CNC Strip Cutting Machine/ Welding Equipment, to form up production lines of assorted finished products: H Beam Production Line, and BOX Beam Production Line, etc.

C. Wuxi JACK Strength on Plate End Milling Machine:

1. Leading Position of Wuxi JACK on Plate End Milling Machine:

1) Edge Milling Machine is one of the “fist” products of Wuxi JACK. Over the years, Wuxi JACK has accumulated rich experience in its design/ producing/ validating/ commissioning and service;

2) All the plate Edge Milling Machine delivered by Wuxi JACK are kept at top level in terms of quality and performance in the market;

3) Wide variety of Wuxi JACK Plate Edge Milling Machine delivered for Chinese and Overseas customers: (Fig.7,8)

2. Technical Superiorities of Wuxi JACK Edge Milling Equipment:

Over the past decades, Wuxi JACK takes the lead in delivery of this Edge Milling Machine, and have gained our own technical advantages, including but not limited to:

1) Core Working Unit of Milling Head: Higher power and efficiency milling head adopted, 7.5kW compared with 5.5kW from many same trades. Under special requirement, 9.3kW and 11kW are also available for the Edge Milling Machine;

High power and capability milling head in Wuxi JACK Edge Milling Machine: (Fig.9)

2) Reasonable Structure and Operation of Milling Heads in Plate Edge Beveling Machine:

a) In Wuxi JACK Edge Milling Machine, its spindle revolution has 6 grades adjustment, which is made by hand with handwheel at rear side of milling unit;

b) Comparatively, milling units of some same trades have only 2 grades speed change, made with uncovering spindle box and replacing gear, which is time consuming and less precise control;

3) High Precision Linear Guiderails in Wuxi JACK Plate Edge Beveling Machine:

a) Precise linear guiderails are assembled onto Wuxi JACK Edge Beveling Machine (Edge Milling Machine), guaranteeing highest degree of precision and consistency in machine running, compared with practice of “ordinary guiderails welded onto the equipment” taken by many same trades Edge Milling Equipment;

b) Superior quality linear guiderails in Wuxi JACK sheet metal Edge Milling Equipment: (Fig.10)

4) The unique feature of hydraulic loading/ unloading unit (This SXBJ-3 double heads plate Edge Milling Machine adopts it also) makes metal plate handling much less stressful…

D. Customer Distribution on Wuxi JACK Edge Milling Machine:

1) Up to now to the year of 2021, Wuxi JACK has delivered hundreds of Plate Edge Milling Machine in various models and configurations, from single head XBJ-3/6/9, to double heads SXBJ-15/16/18, up to four heads GFXBJ-18/20/23 to customers across the globe;

2) For more detail, please check the product family of “Edge Milling Machine”.