Background of This Blog on Metal Structure Beam End Face Edge Milling Machine:

1. Business Prosperity: In Sep. and Oct. 2023, Wuxi JACK won several foreign trade businesses on End Face Edge Milling Equipment, for 6 overseas customers covering 7 sets of different structures and specifications;

2. This embodies Wuxi JACK strength and leading edge in the realm of Metal Structure Beam End Face Edge Milling Equipment development;

3. Topics Here on Metal Structure BOX H Beam End Face Milling Machine:

Business Cases on Wuxi JACK Metal Structure Flange Milling Machine in Sep. and Oct. 2023:

1) 1 set of DX0815 Metal Structure Flange Milling Machine with Special Made Workpiece Fixture;

2) 1 set of DX1530 Metal Structure BOX H Beam End Face Milling Machine with Special Care on Shipment;

3) 2 sets of “Standard” DX1520 Metal Structure Flange Milling Machine;

4) 1 set of Medium Large DX2525 Metal Structure BOX H Beam End Face Milling Machine;

5) 1 set of XBJ-12 Single Head Long Stroke Sheet Metal Steel Plate End Edge Milling Machine with Hydraulic Drive Loading System and 1 Year Use Consumables;

6) 1 set of SXBJ-12 Double Heads Long Stroke Sheet Metal Steel Plate End Edge Milling Equipment;

A. Business Cases on Wuxi JACK Metal Structure Flange Milling Machine in Sep. and Oct. 2023:

In this 2 months, Wuxi JACK signed contract and got advance payment on 7 sets of End Face Edge Milling Machine, currently either finished production, or in its Order to Delivery circle:

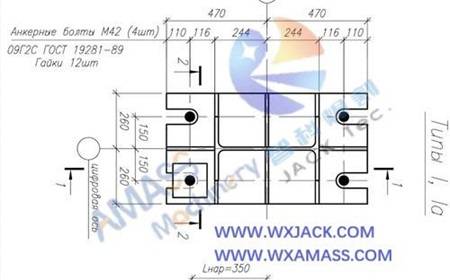

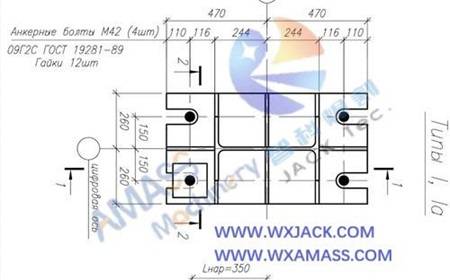

1. DX0815 Metal Structure Flange Milling Machine with Special Made Workpiece Fixture: (Fig.1)

1) Business Background: This is a new middle European customer. As renowned product at this market, Wuxi JACK produced DX series Metal Structure BOX H Beam End Face Milling Machine has gained high recognition;

2) Main Specification: This H Beam End Face Milling Machine has max. machining area of 800mm height and 1500mm width;

3) Main Focus on DX0815 Metal Structure Flange Milling Machine:

a) The primary topic in the process of 1 month business negotiation is on workpiece fixture, which is vertical oriented flange;

b) Specifications: This flange has 940mm length, 520mm width, and 60mm thickness:

c) Front view on workpiece flange to be machined in DX0815 Metal Structure Flange Milling Machine: (Fig.2)

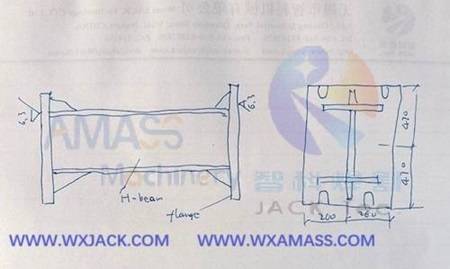

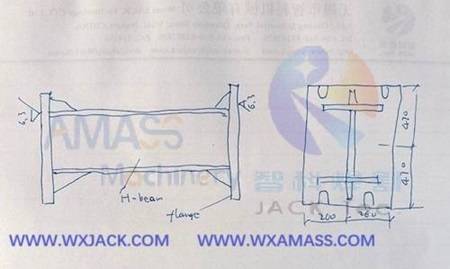

d) Side view on workpiece flange of DX0815 Metal Structure BOX H Beam End Face Milling Machine: (Fig.3)

2. DX1530 Metal Structure BOX H Beam End Face Milling Machine with Special Care on Shipment: (Fig.4)

1) Business Background: Customer is also new from Belarus. Besides DX1530, the customer also placed order on a set of HJ20 Metal Steel Structure Longitudinal Straightening Machine;

2) Characteristics of DX1530 Metal Structure BOX H Beam End Face Milling Machine:

a) Size: DX1530 belongs to conventional model Metal Structure Flange Milling Machine, which has Max. milling surface of 1500mm height by 3000mm length;

b) The main concern is its shipment: DX1530 is too large for 20GP container; While too empty for 40GP: Not cost effective;

c) For this reason, In Aug. 2023, a St. Petersburg customer shipped DX1530 Metal Structure Flange Milling Machine by means of truck: (Fig.5)

d) For this Belarus customer, DX1530 will be stuffed together with HJ20 into 40GP container;

3. “Standard” DX1520 Metal Structure Flange Milling Machine: (Fig.6)

1) Business Background: Customer has business ally with Wuxi JACK for over decades, and trust each other in full proof;

2) Characteristics of DX1520 Metal Structure BOX H Beam End Face Milling Machine:

a) Wide Use: This model accounts for the No.1 selling volume of Metal Structure Flange Milling Machine;

b) Main Specifications: This model fulfils machining on workpieces with cross section sizes up to 1500mm height and 2000mm width, which fits on output products from H Beam Production Line;

4. Medium Large DX2525 Metal Structure BOX H Beam End Face Milling Machine: (Fig.7)

1) Business Background: The Chelyabinsk based customer also has long term partnership with Wuxi JACK, who orders not only Metal Structure Beam End Face Edge Milling Machine, but also other Welding and Cutting Equipment;

2) Technical Features of DX2525 Metal Structure Flange Milling Machine:

a) Specification: As medium large model, DX2525 produces machined working parts with cross section size up to 2500mm height by 2500mm width;

b) Applicable Workpieces: It can not only be used on conventional welding BOX/ H / T Beams, but also other metal structures, such as pipe/ tank/ cylinder structure, as shown in Fig.7;

c) Operation: Also shown in Fig.7, operator needs to stand on motorized lifting platform, moving vertically along upright column of the Metal Structure Flange Milling Machine, for close distance convenient operation and watch;

5. XBJ-12 Single Head Long Stroke Sheet Metal Steel Plate End Edge Milling Machine with Hydraulic Drive Loading System and 1 Year Use Consumables: (Fig.8)

1) Business Background: Customer contacted with Wuxi JACK on initiative, knowing high quality and superior performance of our XBJ series Edge Milling Machine;

2) Technical Specialties of XBJ-12 Sheet Metal Steel Plate End Edge Milling Machine:

a) Milling Head: Produced by Taiwan professional supplier E-LONG, model MU-6S. Many excellent technical performances embedded, making the Edge Milling Machine superior;

MU-6S milling head for high end Edge Milling Machine: (Fig.9)

b) Wuxi JACK solitary owned Hydraulic Drive Workpiece Handling System for Edge Milling Equipment: (Fig.10)

c) Specifications: The max. size of steel plate in this Edge Milling Machine is: 12m length/ 4m width/ 100mm thickness;

6. SXBJ-12 Double Heads Long Stroke Sheet Metal Steel Plate End Edge Milling Equipment: (Fig.11)

1) Business Background: Customer is a Moscow based large company, who, although the 1st time doing business with Wuxi JACK, has long time heard of us because of our superior quality products;

2) Technical Features of SXBJ-12 Double Heads Sheet Metal Steel Plate End Edge Milling Machine:

a) Milling Head Quantity/ Productivity/ Beveling: With 2 pieces of 7.5kW milling head installed, this SXBJ-12 Edge Milling Equipment can produce straight/ lower/ upper edges chamfers with one time movement of milling heads along working table (Also workpieces edge), doubling working efficiency:

Finished carbon steel plate with straight/ lower/ upper edges chamfers from Wuxi JACK double heads Edge Milling Equipment: (Fig.12)

b) Specifications: The largest sheet metal applicable for this SXBJ-12 double heads Edge Milling Machine: 12m length/ 4m width/ 100mm thickness;

c) Milling heads in this SXBJ-12 Edge Milling Machine is Chinese mainland produced HD-750: (Fig.13)

B. Common Points and Variations on Metal Structure Beam End Face Edge Milling Equipment:

1. Common Points of Metal Structure Beam End Face Edge Milling Machine:

1) Task: Carry out high speed end face or edge machining on workpieces;

2) Core Working Unit: 7.5/ 9/ 11kW milling head with adjustable spindle revolutionary speed;

2. Variations of Metal Structure Beam End Face Edge Milling Equipment:

a) XBJ Series Edge Milling Machine:

i. Degree of Freedom: Focuses on 2-dimensional sheet metal: Milling head performs milling on linear trace;

ii. Specifications varies from 3,000mm length (XBJ/ SXBJ-3) to 18,000mm length (XBJ/ SXBJ-18);

b) DX Series H Beam End Face Milling Machine:

i. Degree of Freedom: Focuses on 3-dimensional plane: Milling head performs milling on X / Y axis simultaneously;

ii. Specifications varies from DX0815 to DX6080 (Max. valid milling height is 6000mm).

C. Wuxi JACK Leading Position on Edge Milling Machine and H Beam End Face Milling Machine:

1. Technical Superiorities of Wuxi JACK Metal Structure Flange Milling Machine:

1) Advanced Technology: We have numerous exclusively owned function cells and function elements, such as oil cylinder drive loading system/ Milling angle HMI (Human machine interface) management/ CNC H Beam End Face Milling Machine, etc.;

2) Top Grade Elements: We select best outsourced parts, such as heavy duty precise linear guiderail/ Milling head, etc.;

2. Commercial Performance: Wuxi JACK produced Metal Structure Flange Milling Machine takes 1st – tier supply in industry and market for over decades, since the year of 2009.