Background of This Blog on LHZ4055 Large Column Boom Welding Machine:

1. Business Case: In Nov. 2024, Wuxi JACK delivered a set of LHZ4055 model Large Welding Manipulator to customer site. The customer is a famous foreign company based in Shanghai China, for producing pressure vessels;

2. Purpose: This short article will have brief introduction on this LHZ4055 Large Column Boom Welding Equipment, and expand to technical, commercial use of this important and widely applied welding machine tool;

3. Topics Here on LHZ4055 Large Welding Column Boom:

Major Technical Specifications of LHZ4055 Large model;

Technical Characteristic of LHZ4055 Large model;

Mechanical Main Frame of LHZ4055 Large model;

Summary on Wuxi JACK LHZ Series Welding Manipulator

A. Major Technical Specifications of LHZ4055 Large Welding Column and Boom:

Below is this set of Wuxi JACK LHZ4055 being installed at customer facility: (Fig.1)

1. Function: This Large Welding Manipulator is for welding various seam on metal vessel and metal structure members;

2. Workpiece Size: The horizontal moving stroke of horizontal boom is 5,500mm, and vertical stroke is 4,000mm. So, the max. length of workpiece is around 5,500mm, with max. diameter around Φ3,500mm (Considering height of welding turning rotator for laying workpiece):

Workpiece of LHZ4055 Large Welding Column Boom: Large pressure tanks (Fig.2)

3. Welding Power Supply: American Lincoln brand Power Plus 1000HD SAW (Submerged arc welding machine), with RCH-1 welding wire feeding unit, and welding controller: (Fig.3)

4. Welding Seams Fabricated from Column Boom Welding Equipment:

1) By means of boom horizontal movement, longitudinal seams of either pipe internal and external can be fabricated;

2) By means of workpiece rotation on welding roller bed, circumferential seams of either pipe internal and external can be fabricated;

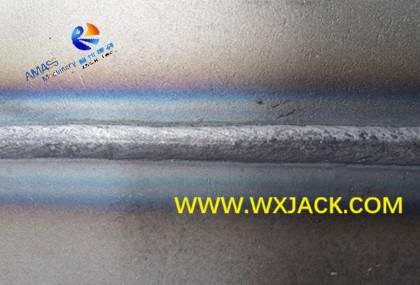

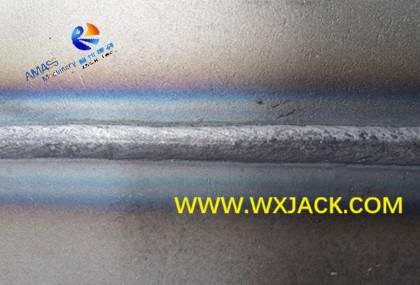

3) The SAW welding seam fabricated from LHZ4055: (Fig.4)

5. Application Form: Worked with SAW welding machine (power supply) and welding roller bed, this LHZ4055 welding machine tool can work as welding center:

The bolt adjusting welding turning roller and LHZ4055 Large Welding Manipulator, composing simple and flexible welding center at customer workshop: (Fig.5)

6. Cable Length: The cable of SAW welding power supply has 20m length; The cable of SAW welding control console has 15m length.

B. Technical Characteristic of LHZ4055 Large Column Boom Welding Equipment:

1. Work Motion: This Large Welding Manipulator has fixed base (Not movable). Its upright column can be revolved ±180° with manual push, and locked in place by means of securing lead nut, after the upright column reaching expected angular position;

2. Adjusting for Varied Diameters of Workpiece: Assembled onto the upright column, the horizontal boom can move up or down under motor drive, when diameter of pressure vessels change. The vertical direction moving speed of horizontal boom is constant: 1000 mm/min.;

3. Longitudinal Welding Speed: This is also horizontal boom horizontal moving speed. It can be adjusted within the scope of 120~ 1200 mm/min, controlled with A.C. inverter, and displayed instantaneously on operating pendant of the LHZ4055 Large Welding Column and Boom: (Fig.6)

4. Circumferential Welding Speed: This is realized with rotation of turning rollers of welding roller bed. Workpiece is laid onto welding rotator, and revolves together with turning rollers. It is also adjustable with A.C. inverters;

5. Welding Torch Position Adjustment: This is for fulfilling satisfactory welding quality on workpieces. For this aim, there is a small cross slides, being installed at front end of horizontal boom. Welding torch is assembled onto this small cross slides. The cross slides has 200mm adjusting stroke in both horizontal and vertical direction, which is also adjusting allowance of welding torch: (Fig.7)

6. Welding System of LHZ4055 Column Boom Welding Machine:

This includes:

1) Lincoln brand Power Plus 1000HD SAW power supply, laid onto mechanical square base of LHZ4055;

2) SAW Welding flux recycling machine: Installed at front end of horizontal boom: (Fig.8)

3) Welding flux feeding and recycling tubes: Being installed all the way along external surface of horizontal boom;

4) Welding wire reel and wire tensioning unit: Being installed at front end of horizontal boom. For different sizes of welding wire, the tensioning unit can work on different specifications of diameters, making sure welding wire straight in feeding;

5) Lincoln SAW Welding Power Supply Control Console: This is also installed at front end of horizontal boom;

Summing up, the welding supplementary units listed above, being assembled at front end of horizontal boom of the LHZ4055 Large Welding Column and Boom: (Fig.9)

C. Mechanical Main Frame of LHZ4055 Large Welding Column Boom:

The final assembled mechanical body of LHZ4055, being erected at assembly workshop of Wuxi JACK: (Fig.10)

The mechanical system of this large machine tool is consisted of five major parts:

1. The Upright Erected Column of this Large Column Boom Welding Machine:

1) This upright column is solid and has high intensity, serving as trunk of the machine tools;

2) Safety Assurance: There is an array of rectangular holes at front surface of the upright column, serving as safety purpose during operation: Suppose there happens sudden falling down horizontal boom, the safety pins will be ejected out immediately, and plug into safe holes. In this way, the horizontal boom will not smash onto workshop floor, or even operators at running site;

2. The Horizontal Boom of Large Welding Manipulator:

1) This is operating arm of the machine, serving as manipulating arm of welding operation. This is also product name “Welding Manipulator” getting from;

2) There is one critical technical index involved with the horizontal boom: Deflection. For this LHZ4055 Large Column Boom Welding Equipment, the stipulated deflection required from customer is ≦4mm/m. Which means, for every 1,000mm extension of horizontal boom, the drooping down at front end of horizontal boom should be less than 4mm;

3) For acquiring such strict deflecting tolerance, the horizontal boom needs to be precisely machined first, then annealed, so as to gain sufficient high precision and strong strength;

3. Cross Slides of Welding Column Boom:

1) Role: This is operating juncture of the Welding Manipulator. The horizontal boom and upright column are joint in perpendicular here, and serves as ankle of working motion along horizontal direction (X axis) and vertical way (Y axis);

2) For Wuxi JACK produced Welding Column and Boom, we select heavy duty cross slides, to guarantee on reliable operation of the welding machine tool: (Fig.11)

4. Cross Roll Bearing of Column Boom Welding Equipment:

1) This is another important assembly, serving as mounting base of the upright column onto square base bed, and serves as pivot of column revolve;

2) Considering horizontal boom mounted onto upright column by means of cross slides, this cross roll bearing also bears on weight of the mechanical main frame of LHZ4055 Column Boom Welding Equipment: (Fig.12)

3) As can be observed from the above photo, cross bearing is precisely machined and then coated, for making sure its rigidity/ precision/ anti-abrasion performance;

5. Square Base: The entire set of LHZ4055 stationary Large Welding Manipulator is mounted onto this stationary square base, by means of cross roll bearing. To withhold heavy total weight of the entire set of LHZ4055, there is counterweight installed inside of this square base, maintaining balance and steady operation of the LHZ4055 large machine tool.

D. Summary on Wuxi JACK LHZ Series Welding Manipulator:

1. Extensive Application: As basic form and widely applied welding equipment, LHZ models Column Boom Welding Machine can been seen at every facilities producing Pressure Vessel, Petro-Chemical, Tank, Pipe, Boiler, etc.;

2. Strong Points: This cross structure welding equipment has advantages of simple constructure, flexible form and abundant configuration, with wide range of specifications;

3. Wuxi JACK Strength: As an excellent Chinese professional supplier in Welding and Cutting industry, Wuxi JACK is very good at designing and manufacture various models of Welding Column Boom, from light duty LHZ2020, to medium duty LHZ3030, to heavy duty here discussed LHZ4055, or larger models LHZ8080... With welding models of SAW/ GMAW/ MIG/ MIG, or even being used in other steps of process technology: Painting, Testing, Assembly, etc.