Background of This Blog on Welding Manipulator and Rotator:

1) Business Case: In middle Jan. 2025, Wuxi JACK will ship a group of pipe/ tank welding center equipment: LHZ4040 Stationary Welding Manipulator and HGZ10 Self Adjustable Movable Welding Rotator, for a customer in East Europe. By the date of this blog finished and logged (Jan.3rd 2025), this group of welding center equipment has been finished production/ test/ painting at Wuxi JACK company, and ready for forwarder arranging on shipment. According to customer schedule, it will be put into use at end user in March 2025;

2) Significance: As the most popular welding machinery on cylindrical parts fabrication, Welding Manipulator and Rotator sees very extensive use. There are numerous technical specialties with this equipment complex of Welding Column Boom and Movable Welding Turning Roller, which distinguishes Wuxi JACK products from those of other suppliers’ produced machine tools. It is meaningful to have a brief introduction here, to better demonstrate on our exceeding strength, and responsibility for customers;

3) Topics Covered Here on Welding Manipulator and Rotator:

This short article aims on having a brief discussion on technical characteristic of the welding center machinery, and leading superiorities of our products:

Specifications of LHZ4040 and HGZ10 Welding Manipulator and Rotator;

Technical Strong Points of Wuxi JACK LHZ4040 Welding Column Boom;

Technical Strong Points of Wuxi JACK HGZ10 Movable Welding Turning Roller;

Summary on Wuxi JACK Welding Equipment

A. Specifications of LHZ4040 Stationary Welding Manipulator and HGZ10 Automatic Movable Welding Rotator:

1. Composition of Welding Manipulator and Rotator:

This group of pipe welding center equipment is composed of:

1) 1 set of LHZ4040 Stationary Welding Manipulator, of column manual revolve, equipped with:

a) 1 set of SAW (Submerged arc welding) power supply;

b) Welding flux recovery machine;

c) Welding wire feeding and straightening unit;

2) 3 sets of HGZ10 Automatic Movable Welding Turning Roller, with manual operating moving capability. Each set of the Movable Welding Rotator has one set of driving and idler section roller bed respectively;

1) LHZ4040 Welding Manipulator being erected and assembled in Wuxi JACK workshop: (Fig.1)

2) 3 sets of HGZ10 Movable Welding Rotator finished assembled, tested, and painted at Wuxi JACK facility: (Fig.2)

3) Welding head mechanism at front end of LHZ4040 horizontal boom: Welding torch, small cross slides, SAW welding control console, welding flux hopper, welding wire feeding reel, welding wire strainer: (Fig.3)

4) 1250A SAW welding power supply produced by HUAYUAN, equipped with LHZ4040 Welding Column Boom: (Fig.4)

2. Function and Workpiece Sizes of LHZ4040 Welding Manipulator and Rotator:

This pipe welding center machine group is for flexible and high efficient pipe/ tank production:

1) Perform longitudinal welding for fabricating on each segment of cylindrical part;

2) Implement on circumferential welding for joining segments of pipes/ tanks into longer ones;

3) The max. diameter of pipe/ tanks can be Φ3,600mm;

4) The max. length of finished joint pipe can be 15,000mm;

5) The max. SAW welding current can be 1250A;

Test on SAW welding performance of LHZ4040 Welding Manipulator at Wuxi JACK, with trial welding on test piece: (Fig.5)

B. Strong Points of Wuxi JACK LHZ4040 Welding Column Boom:

1. General Brief on Technical View of Welding Manipulator:

As a kind of “Simple” structured welding equipment, this machine tool is mainly composed of:

1) 1 piece of horizontal orientated boom, serving as operating manipulator of welding, moving in directions of:

a) Horizontal way (X axis): In adjustable welding speed, for fulfilling longitudinal welding;

b) Vertical way (Y axis): In constant speed, for accommodating on varied diameter of workpiece;

2) 1 piece of upright erected solid column, serving as trunk of the entire Welding Column Boom;

3) Large Cross slides being assembled between horizontal column and upright boom, serving as articulate (joint) on X and Y axis movement of horizontal boom;

4) Mechanical base of the entire set of Welding Column Boom, serving as leg and feet, either in the form of stationary square bed, or as motorized moving trolley;

5) Cross roll bearing be assembled between upright column bottom and mechanical base, serving as articulate (joint) of upright column installation and revolve;

2. Superior Technical Characteristics of Wuxi JACK Welding Manipulator:

Excellence comes from niceties, which can be embodied in:

1) 100% safe operation: During work, the most serious threat comes from sudden falling down of horizontal boom, which may smash on operator, equipment and workshop floor. To eliminate this safety risk, Wuxi JACK adopts measures of:

a) High power braking motor for driving elevation of horizontal boom: (Fig.6)

b) Row of safety holes cut into the upright column, and safety pins for ejection into the holes: (Fig.7)

c) Reliable high quality guide and transmission unit for boom elevation, and limit switch: (Fig.8)

2) No droop down of horizontal boom: Boom drooping down is one of the most serious technical difficulties and quality hidden trouble for operation of Welding Manipulator. For Wuxi JACK produced Welding Column Boom, we eliminate this hidden risk by means of:

Enlarged sizes of cross section of horizontal boom (300mm plus length and width), to fully guarantee on its sufficient mechanical rigidity and strength: (Fig.9)

3) Large cross slides between horizontal boom and upright column: Heavy duty loading capacity, of smooth rolling and transmission, as ideal joint for boom both directions. The eccentric rollers can also have inching adjustment: (Fig.10)

4) Small cross slides at the front end of welding arm, making sure high precision welding torch position during welding operation, and hence superior welding quality of Welding Manipulator: (Fig.11)

5) Welding wire straining unit, guaranteeing on always reliable and smooth feeding of welding wire during welding operation, and hence fully guaranteeing on top grade welding quality: (Fig.12)

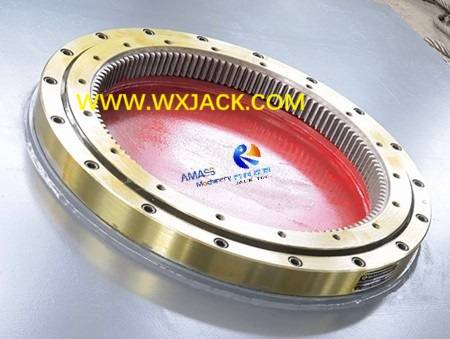

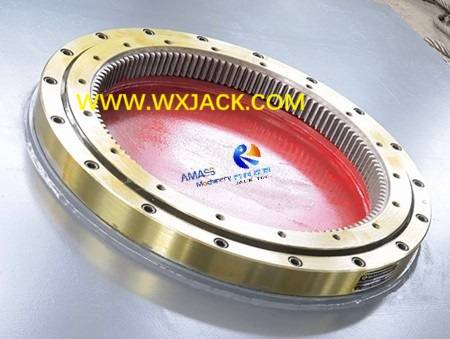

6) Cross roll bearing: Heavy duty loading capacity, making sure smooth ±180° revolve of upright column, and solid support of Welding Manipulator:

a) Cross roll in assembled between column bottom and mechanical base: (Fig.13)

b) Cross roll after disassembled and painted for delivery: (Fig.14)

C. Strong Points of Wuxi JACK HGZ10 Self Adjustable Movable Welding Turning Roller:

1. Technical Characteristic of Self Adjustable Movable Welding Rotator:

1) Self-adjusting, or automatic, is the most often and convenient way of turning roller span adjustment, to cater on different diameters of pipes. By loading pipes onto welding roller bed, the turning rollers will swing automatically, based on weight and diameter of workpiece;

2) Manual Movable: There are 4 pieces of wheels being assembled at bottom of the welding roller bed. The movement of the Automatic Movable Welding Turning Roller is by means of hand operation, to be suitable for different length of each segment pipe for joint circumferential welding;

3) Task: With ± 0° ~ 360° revolve of turning rollers, of which, revolving linear velocity is welding speed of the Movable Welding Turning Roller, and can be adjusted with A.C. inverter and shown in digital display, circumferential welding seam can be completed user friendly on pipes:

Hand held operating pendant of HGZ10 Movable Welding Rotator: (Fig.15)

2. Technical Superiorities of Wuxi JACK Self Adjustable Movable Welding Turning Roller:

1) Current Status: As the “simplest” welding equipment in terms of structure and working principle, welding rotator can be produced by every company in Welding and Cutting Machinery industry. Accordingly, there exist very fierce competition in supplying market of welding rotator. This brings along negative impact, and price of welding roller bed grows unreasonable low: Many suppliers cut manufacturing cost of the Welding Turning Roller to unreasonable low level, for the purpose of winning order from customers, not caring on quality and performance of welding rotator in the future at customer site;

2) Wuxi JACK persist on supplying reliable and consistent superior quality Welding Turning Roller for customers, even facing the challenge on losing business from customers. This is reflected in below aspects, but not limited to:

a) Heat Treatment: All the metallic welding turning rollers are went thru heat treatment of quenching, so as to promise long service life of Welding Rotator:

Metallic and rubber turning rollers of HGZ10: (Fig.16)

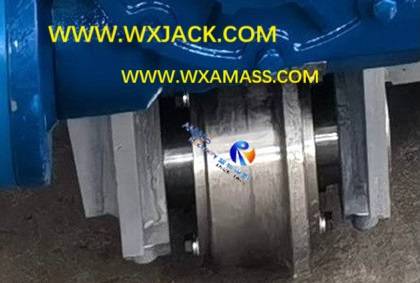

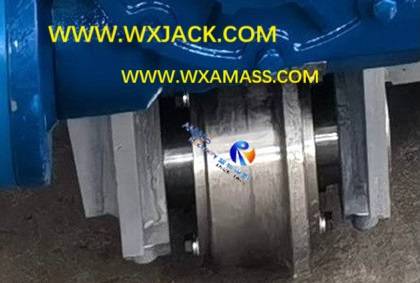

b) Unison Boring Machining: All the moving wheels of the Movable Welding Rotator are clamped integrally into machining machines for boring. In this way, after assembly, the 4 pieces of wheel shafts are in the perfect same plane, so as to have uniform force distribution on the 4 moving wheels, and in turn fully guarantee on stable and smooth movement of welding roller bed during operation:

Moving wheels of HGZ10 Movable Welding Turning Roller: (Fig.17)

c) Quenched gears for transmission of driving section welding roller bed: This greatly improves on mechanical performance of the gears, and hence fully guarantees on reliable, persistent and long term welding operation:

Groups of quenched gears being assembled in HGZ10 Movable Welding Rotator: (Fig.18)

D. Summary on Wuxi JACK Welding Manipulator and Rotator:

1. Wuxi JACK Tenet on Supplying Machine Tools for Customers:

As can be drawn conclusion from the above brief discussion, as the Chinese saying going: Details determine on failure or success. Adhering to the spirit of responsible for customers, Wuxi JACK engineering team always pursuit on the best performance on every of our product, including those details visible or invisible for customers. This helps us sacrificing short term benefit, and hold on long term development. We believe customer recognizing our craftsmanship spirit on our products, and focus on delivering the best products for customers, including this group of LHZ4040 and HGZ10 Welding Manipulator and Rotator we introduced here;

2. For more detail introduction on these welding center machine tools, please check product pages of:

1) Welding Column Boom;

2) Movable Welding Turning Roller