Subject of This Blog on Two Welding Modes with 3 in 1 H Beam Welding Machine:

1. Background: In June 2024, during technical communication with an overseas customer on 3 in 1 H Beam Fabrication Machine, customer raised question as below:

1) Technical comparison between SAW and CO2 welding being applied in 3 in 1 H Beam Assembly Welding Straightening Machine;

2) Which welding mode is more appropriate for their H Beam production?

2. Significance: The above 2 questions are typical queries during business negotiation with many clients by Wuxi JACK, which are main consideration for proper selection on configuration of H Beam 3 in 1 Machine;

3. Topics in This Blog on Welding Mode in H Beam 3 in 1 Fabrication Machine:

Business Case on Communicating 3 in 1 H Beam Fabrication Machine;

Technical Features of SAW and CO2 for being Applied in 3 in 1 H Beam Welding Machine;

General Guideline on Selecting SAW or GMAW CO2 for H Beam 3 in 1 Fabrication Machine;

Technical Comparison between SAW and GMAW CO2 for 3 in 1 H Beam Assembly Welding Straightening Machine;

Wuxi JACK Technical Strength on Providing Appropriate Configutation of H Beam 3 in 1 Machine for Customer

A. Business Case on Communicating 3 in 1 H Beam Fabrication Machine:

1. Customer Request on 3 in 1 H Beam Welding Machine:

At the initiation of communication, customer gave specifications of their H Beam:

1) H Beam Web Height: 150mm to 610 mm;

2) H Beam Flange Width: 150mm to 350 mm;

3) Thickness of Plates: 3.2mm to 25 mm, mostly from 3.2mm to 12.5mm;

2. Wuxi JACK Proposal on H Beam 3 in 1 Machine:

Based on customer request, which covers thickness for SAW and CO2 welding. So, we proposed 2 welding options for customer choice:

1) SAW: The H Beam 3 in 1 Machine will be equipped with 2 sets of SAW welding power supply/ control console and torch;

2) GMAW CO2: Or, equipped with 2 sets of GMAW CO2 welding system;

So, which is more welding mode proper for customer choice?

B. Technical Features of SAW and CO2 for being Applied in 3 in 1 H Beam Welding Machine:

1. SAW in Application of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) What Is: SAW, short for “Submerged arc welding”, is widely used in the field of H Beam production. It is the No.1 welding mode, accounting for over 80% ~ 90% for being adopted in 3 in 1 H Beam Fabrication Machine;

2) Technical Features and Usage of SAW for H Beam 3 in 1 Machine:

a) Welding Current: SAW has relatively large welding current, in the scope of 100A ~ 1000A, usually with working current of 500A ~700A;

b) Welding Consumables: With Φ2.5mm ~ Φ4.0mm solid welding wire and SJ101 welding flux;

c) Usage: For welding on carbon steel with relatively large thickness: 8mm or above. In other words, SAW is “heavy” welding form for H Beam 3 in 1 Machine;

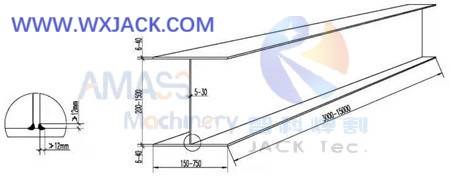

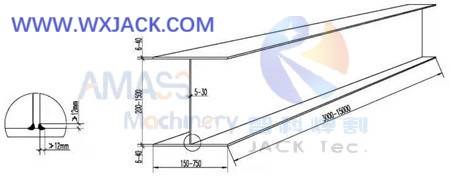

3) SAW for welding on H Beam in H Beam 3 in 1 Fabrication Machine: (Fig.1)

2. GMAW CO2 in Application of 3 in 1 H Beam Fabrication Machine:

1) What Is: GMAW CO2, short for “Gas metal arc welding with CO2 gas shielded”, is the other important welding mode in H Beam production, besides SAW;

2) Technical Features and Usage of CO2 Welding for 3 in 1 H Beam Welding Machine:

a) Welding Current: CO2 has smaller welding current, in the scope of 100A ~ 500A, usually with working current of 350A ~ 400A;

b) Welding Consumables: With cored welding wire, for welding on ferrous and non-ferrous metal of thinner thickness: 2mm to 8mm;

c) Welding Seam Strength: CO2 welding delivers higher IK value welding seam. So, it is appropriate for welding on “long and slim” H Beam in H Beam Fabrication Machine;

d) In other words, CO2 welding is “delicate” welding mode for H Beam 3 in 1 Machine;

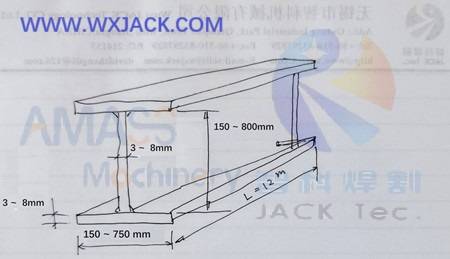

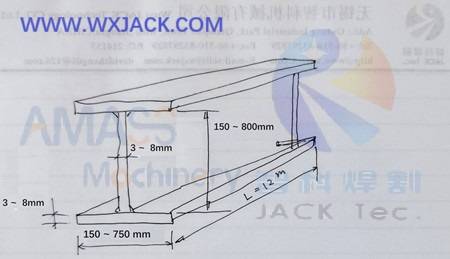

3) CO2 welding mechanism in H Beam 3 in 1 Fabrication Machine: (Fig.2)

C. General Guideline on Selecting SAW or GMAW CO2 for H Beam 3 in 1 Fabrication Machine:

1. SAW: Applicable H Beam Specifications for 3 in 1 H Beam Assembly Welding Straightening Machine:

Typical H Beam sizes for SAW H Beam 3 in 1 Fabrication Machine: (Fig.3)

a) H Beam Flange and Web Thickness: 5mm ~ 40mm;

b) H Beam Web Height: 200 ~ 1500mm;

c) H Beam Flange Width: 150 ~ 750mm;

Especially for producing thickness from 8mm ~ 40mm, SAW has very good quality and efficiency for performance of the H Beam 3 in 1 Machine:

Welding H Beam produced from SAW in 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.4)

2. GMAW CO2: Applicable H Beam Specifications for 3 in 1 H Beam Welding Machine:

Typical H Beam sizes for GMAW CO2 with H Beam 3 in 1 Machine: (Fig.5)

a) H Beam Flange and Web Thickness: 3mm ~ 8mm;

b) H Beam Web Height: 150 ~ 800mm;

c) H Beam Flange Width: 150 ~ 750mm;

Especially for producing long and slim H Beam with 3 in 1 H Beam Welding Machine:

a) H Beam length longer than 6m,

b) H Beam height and width 150mm ~ 400mm;

c) H Beam flange and web thickness 3mm ~ 8mm;

GMAW CO2 has very good quality and efficiency for guaranteeing performance of the 3 in 1 H Beam Welding Machine:

Welding seam fabricated from CO2 GMAW with H Beam 3 in 1 Machine: (Fig.6)

3. Wuxi JACK Experience on Selecting Proper Welding Modes for 3 in 1 H Beam Welding Machine:

It depends on the percentage of H Beam with thickness to be produced:

1) If over 60% of H Beam has thickness less than 8mm, then GMAW CO2 is more better for 3 in 1 H Beam Assembly Welding Straightening Machine; For 40% H Beam with thickness higer than 8mm, GMAW CO2 can still produce, but efficiency is lower than SAW;

2) If over 60% of H Beam has thickness equals to or bigger than 8mm, then SAW is more better for 3 in 1 H Beam Fabrication Machine. For 40% H Beam with thickness less than 8mm, SAW can still produce H Beam, but will generate some deformation on finished H Beam.

D. Technical Comparison between SAW and GMAW CO2 for 3 in 1 H Beam Assembly Welding Straightening Machine:

1) SAW welding being used in 3 in 1 H Beam Fabrication Machine: (Fig.7)

2) GMAW CO2 welding being used in 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.8)

Below are Illustration on Key Aspects on SAW Compared with GMAW CO2 in 3 in 1 H Beam Welding Machine:

1. Welding System: Welding power supply/ control console/ welding torch to be used in H Beam 3 in 1 Machine, SAW versus CO2: (Fig.9)

2. Welding Consumables of SAW Versus GMAW CO2 Welding in 3 in 1 H Beam Welding Machine: (Fig.10)

3. Welding Operation with SAW Versus GMAW CO2 Welding in 3 in 1 H Beam Welding Machine:

a) SAW has user friendly operation, no spark light during welding process;

b) CO2 welding generates strong light, which is harmful on operator eyesight.

So, need to put on helmet during operation of the H Beam 3 in 1 Machine: (Fig.11)

4. At customer site with SAW Versus GMAW CO2 Welding of 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.12)

E. Wuxi JACK Technical Strength on Providing Appropriate Configutation of H Beam 3 in 1 Machine for Customers:

1. Leading Technology: Wuxi JACK takes lead in developing PHJ and ZHJ series H Beam Assembly Welding Straightening Machine over the past 15 years ever since 2009, on the aspect of design/ performance/ technique/ operation, etc.;

2. Rich Experience: With around 600 sets of the H Beam 3 in 1 Machine delivered for customers in China and overseas, Wuxi JACK engineering team has accumulated rich experience and abundant data, which help us providing the most suitable design 3 in 1 H Beam Welding Machine for customer with various requirement;

3. For more detailed introduction on Wuxi JACK superiorities of our H Beam 3 in 1 Machine, it is illustrated in slides: “Quick understanding on Wuxi JACK H Beam 3 in 1 Fabrication Machine”.