Background of This Article on Proper Installing H Beam Steel Structure Side Face Milling Machine:

1. Three Critical Topics in Business Discussion: In June 2024, during communication on DX15xx model End Face Milling Machine with a European customer, customer raised concerns on operation of this Side Face Milling Cutter at his company workshop: Solidarity of mechanical main frame/ Dust proof capability of the machine/ Proper controlling mill on circular cylindrical parts accurately and efficiently;

2. Wuxi JACK Reaction: Based on customer concern, Wuxi JACK engineering team gave considerate and in depth answer and proposed solution, relieving customer concern on this Steel Structure Side Face Milling Cutter;

3. Main Topics in This Blog on Steel Structure End Face Milling Machine:

Here we make brief summary on valuable information during this business talk, which can be taken as reference on customer purchasing new Side Face Milling Cutter:

Brief Introduction on Usage, Application and This Business Case of H Beam Steel Structure End Face Milling Machine;

Solidarity and Toughness of Wuxi JACK Steel Structure Side Face Milling Cutter;

Dust Proof Performance of Wuxi JACK H Beam Steel Structure Side Face Milling Machine;

Proper Electric Control on Workpieces of Conventional and CNC Side Face Milling Machine;

Summary on Wuxi JACK Conventional and CNC End Face Milling Machine

A. Brief Introduction on Usage, Application and This Business Case of H Beam Steel Structure End Face Milling Machine:

1. Function and Use of Side Face Milling Machine:

1) DX series H Beam Steel Structure End Face Milling Machine accomplishes end face polishing on: BOX/ Cross/ T/ H Beam/ Pipe/ Any special cross section working parts. has wide application in Metal Building field, especially Steel Structure industry:

Typical workpieces of conventional models Side Face Milling Cutter: (Fig.1)

2) CNC Control: Equipped with CNC controller, CNC-DX models CNC Side Face Milling Machine can be applied on any “special” working parts. The typical ones are circular pieces:

Typical workpieces of CNC End Face Milling Machine: (Fig.2)

2. This Business Case of DX15xx Steel Structure End Face Milling Machine:

This customer is a European Foundry company. They plan to purchase a new Side Face Milling Cutter for polishing on casting parts, which has weight around 10 Tons. The main concern from client on proper use of the machine are:

1) Solidarity of the machine frame, to sustain the heavy weight of castings;

2) Dust proof performance of the machine: The Side Face Milling Cutter will work in very dusty workshop. So, how to protect electric box and system/ hydraulic pump station/ linear guiderail/ lubrication from the dusty environment, to guarantee long term stable running of the End Face Milling Machine, is of vital importance;

3) Control Mode of the machine: The workpiece to be milled in this End Face Milling Machine is cylindrical castings, which has circular cross section. So, selecting proper style of electric control is of vital importance;

Aiming on relieving customer from the above concern, Wuxi JACK give explanation on technical strong points of our Steel Structure Side Face Milling Machine. Briefly introduced as below:

B. Solidarity and Toughness of Wuxi JACK Steel Structure Side Face Milling Cutter:

1. Applicable Workpiece Weights: Our machine is used on milling heavy and large size steel structure workpieces, which usually has weight of over 8 tons ~ 20 tons for DX15xx series standard model Steel Structure Side Face Milling Machine, and over 40 tons for heavy duty models:

10+ ton heavy parts to be milled in Wuxi JACK DX15xx H Beam Steel Structure Side Face Milling Machine: (Fig.3)

2. So, Wuxi JACK H Beam Steel Structure End Face Milling Machine:

1) The hydraulic clamping tables and its headstock;

2) Main motor and reducer;

3) Our guiderail (HIWIN Heavy duty linear guiderail HGH45CA);

4) Mechanical main frame of horizontal bed and upright column;

5) Main motor to drive on milling speed of 100~ 800mm/min.;

Are all suitable to work on customer working parts. Besides, our heavy duty linear guiderail has smaller clearance than box guiderails.

C. Dust Proof Performance of Wuxi JACK H Beam Steel Structure Side Face Milling Machine:

Wuxi JACK engineers give full round introduction to the customer on dust proof performance of each main unit in the Side Face Milling Cutter:

1. Guiderail in Steel Structure End Face Milling Machine:

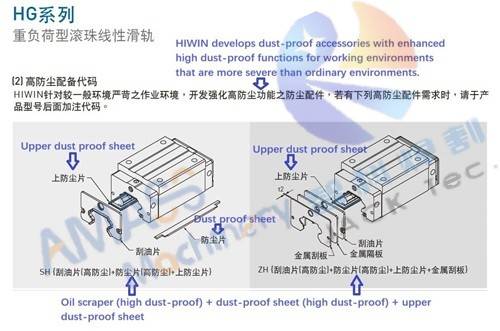

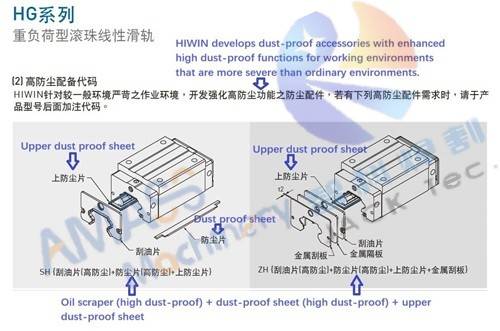

Both horizontal bed and upright column adopt heavy duty ball linear guides, produced by Taiwan HIWIN, and there are two levels of dust proof protection sheets on the slider. Such heavy duty ball bearing precise linear guiderail has far more better dust proof protection level than other kinds of guiderail. This can be embodied on below 2 aspects of:

1) The guiderail itself, we select high dust proof model for Side Face Milling Cutter:

a) Dust proof model guiderail in Wuxi JACK End Face Milling Machine: (Fig.4)

b) HIWIN heavy duty precise linear guiderail on horizontal bed and upright column of Wuxi JACK H Beam Steel Structure End Face Milling Machine: (Fig.5)

2) Dust Proof Protection on Assembling Guiderails onto Bed and Column of Steel Structure End Face Milling Machine:

a) The guide rails on the upright columns are accordion style guide rail guards, made of fireproof cloth;

b) The guide rails of horizontal bed are stainless steel laminated guide rail guards, which completely protect the guide rails;

Wuxi JACK customer workshop: Dust proof protection measures on guiderails assembling onto the Side Face Milling Machine: (Fig.6)

3) One Complement: Many other suppliers adopt ordinary welding guiderail onto their Side Face Milling Machine, which has much lower manufacturing cost than Wuxi JACK, and has much inferior stability/ precision/ dust proof performance on guiding;

2. Hydraulic Pump Station: The independent hydraulic pump station is well sealed and has an air filter in the pump station itself:

Individual placed and well sealed hydraulic pump station in Wuxi JACK conventional and CNC Side Face Milling Machine: (Fig.7)

3. Electric Motor: Electric motor’s protection grade is IP54 and can be fully dustproof;

4. Electric Box and Operating Buttons of Steel Structure End Face Milling Machine:

1) Use buttons with transparent dust covers on the control box;

2) Control cabinet is also sealed to ensure ventilation and heat dissipation while protecting the original electrical components from dust;

5. Lubrication in Steel Structure Side Face Milling Cutter:

Wuxi JACK standard configuration is manual operating lubrication system. Sometimes operator may forget to push on lubricating lever. So, we recommend adopting automatic lubricating system into this Side Face Milling Machine for customer.

D. Proper Electric Control for Workpieces of Conventional and CNC Side Face Milling Machine:

In this business case, cross section of customer casting parts has circular shape. We suggest adopt CNC control into the machine:

1) Improve Accuracy and Efficiency: CNC control greatly improve end face milling trace accuracy and efficiency: The milling head trace on circular trace milling is far more easier and accurate under CNC control. Besides, the end face milling speed has more smooth and subtle management under CNC control;

2) Easier Operator Job: Without CNC, operator needs to spend fairly time and effort to manage on milling head position and change all the while, during milling operation process:

3) Operator works on circular parts without CNC control in Side Face Milling Machine: (Fig.8)

4) Convenient operation of Wuxi JACK CNC End Face Milling Machine: (Fig.9)

5) Milling head position trace control and management in CNC Side Face Milling Machine: (Fig.10)

2. Budget Consideration: CNC End Face Milling Machine adds on around 7% total quotation than conventional A.C. relay and inverter control;

Wuxi JACK CNC-DX1520 CNC End Face Milling Machine: (Fig.11)

E. Summary on Wuxi JACK Conventional and CNC End Face Milling Machine:

Wuxi JACK Leading Position: Over the past 2 decades, we take the lead in supply of DX series H Beam Steel Structure Side Face Milling Machine. Our strong points:

1. Full line of models Side Face Milling Cutter providing for customers: Standard models and special design;

2. Lead on CNC Models: The first company and the best one in Chinese industries for developing numerous models of CNC Side Face Milling Machine;

3. Supply Large Models: Solitary Chinese company to have capability and rich experience on designing and producing heavy duty H Beam Steel Structure End Face Milling Machine, up to models of DX4080 and DX6080: The max. vertical milling stroke is 6m;

4. Superior Quality: The design/ workmanship/ outsourced parts ... of our Side Face Milling Cutter have obvious better level than other suppliers.