Background of This Blog on 3 in 1 H Beam Fabrication Machine:

1) Origin of This Blog: During long time business communication between customers and Wuxi JACK on the product of H Beam Assembly Welding Straightening Integral Machine, there are numerous interesting topics involved in the process;

2) Commercial Significance: These technical topics not only be of critical importance on customers, to make final decision on purchasing H Beam Building and Straightening Machine, reflecting their niche focus of attention, but also play important role on customers selection on specialized configuration on the 3 in 1 SAW H Beam Welding Machine;

3) Promotion Extension: Besides, these technical topics also gives valuable inspiration on Wuxi JACK engineering team, helping guiding us keeps on correct track of Continuous Improvement on this box product of H Beam Steel Structure Fabrication Equipment, making the Wuxi JACK H Beam Fabrication Machine keeping pace with the Times;

4) Example Topics: In this short blog, let us review several of the technical issues between customers and Wuxi JACK, as below:

a) How to Produce Heavy duty H Beam with Integral Function 3 in 1 SAW H Beam Welding Machine?

b) How to Determine the Most Appropriate Configuration of 3 in 1 H Beam Building and Straightening Machine?

c) Which Kind of Welding Seam Penetration is Applicable for 3 in 1 H Beam Assembly Welding Straightening Integral Machine?

d) Is Tapered H Beam Available for being Delivered from H Beam Steel Structure Fabrication Equipment?

e) Summary on Wuxi JACK 3 in 1 H Beam Fabrication Machine

A. How to Produce Heavy duty H Beam with Integral Function 3 in 1 SAW H Beam Welding Machine?

1. Confinement on 2 Passes of Welding Seam with 3 in 1 H Beam Fabrication Machine:

1) Yes, it is possible to make two passes of welding on H Beam, by sending the H Beam to the 3 in 1 H Beam Fabrication Machine the 2nd time;

2) In theory, in extreme cases, all the H Beam (This means 100% of workpieces) can be welded with two passes in the 3 in 1 H Beam Assembly Welding Straightening Integral Machine, if customers do not care for productivity;

3) But obviously, this is not the best solution for customers in terms of both productivity and cost effectiveness;

2. Recommended Proposal with H Beam Building and Straightening Machine:

1) Under the condition over 40% workpieces need to be welded with two passes, we recommend a set of SAW H Beam Welding Machine, for implementing 45° fillet welding, this can get better appearance of welding seam, and higher productivity;

2) A set of Wuxi JACK LHA model SAW H Beam Welding Machine, and its 2 pieces of fabricated H Beam: (Fig.1)

3) Rule of Thumb: The workpieces which should be welded with two passes in 3 in 1 H Beam Fabrication Machine had better not exceed 10%~ 20%, this is recommendation from the viewpoint of ideal productivity.

B. How to Determine the Most Appropriate Configuration of 3 in 1 H Beam Building and Straightening Machine?

1. Division of Workpieces Between 2 Major Categories of H Beam Steel Structure Fabrication Equipment:

1) As we know, in the field of H Beam Steel Structure Fabrication Equipment, PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine has clearly different applicable working parts, from that of typical H Beam Production Line;

2) Of which, H Beam Assembly Welding Straightening Integral Machine has unmatched advantages for producing light to medium duty T Beam/ H Beam:

The welding H Beam produced from Wuxi JACK 3 in 1 SAW H Beam Welding Machine: (Fig.2)

3) While H Beam Production Line has the unique capability on producing heavy duty H Beam;

4) Here, the distinction between light to medium duty H Beam, with heavy duty ones, lies in requirement on size of welding leg: 8mm to 12mm seam height;

2. The Practical Issues Encountered with Customers When Purchasing H Beam Building and Straightening Machine:

1) Ideal Condition: In practical application, if customers have their workpieces clearly falling within either scope of specification mentioned above, this is a simple choice to made;

2) Dilemma: However, many times sees hybrid distribution of H Beams with specifications falling within the scope of both H Beam Fabrication Machine and H Beam Production Line, which is a hard choice to made;

3) For Example, customers have H Beams with flange thickness from 6mm up to 32mm, which cross the line between the 2 types of H Beam Steel Structure Fabrication Equipment;

4) Proposal: Under such condition, we recommend combined solution of H Beam Assembly Welding Straightening Integral Machine together with SAW H Beam Welding Machine. This will not only meet customer demand on producing various sizes of welding H Beam, but also maintain investment on equipment at the minimum level;

5) For more detailed, please check blog: “Find the Most Fitting Proposal on Producing Medium Heavy H Beam with H Beam Fabrication Machine”.

C. Which Kind of Welding Seam Penetration is Applicable for 3 in 1 H Beam Assembly Welding Straightening Integral Machine?

1. Full Penetration Seam Requested by Customer on H Beam Steel Structure Fabrication Equipment:

One of the questions customer posed is, is below welding seam penetration available from 3 in 1 H Beam Fabrication Machine? (Fig.3)

2. For 3 in 1 H Beam Fabrication Machine:

Wuxi JACK engineering team suggestion is no. Because:

1) For welding web with full or partial bevel, the welding current should be large: Over 700A to 800A;

2) While for working welding current of the Integral Function 3 in 1 SAW H Beam Welding Machine, the most frequently selected welding current range is around 500A~ 600A;

3) Although the 3 in 1 H Beam Fabrication Machine is equipped with 1000A specification SAW welding power supply, when welding current exceeds 700A~ 800A, the formed welding seam will sink down;

4) The web with full or partial bevel should be welded in SAW H Beam Welding Machine with 45° fillet welding: Not only considering eligible welding current, but also the best quality of welding seam;

3. What is Recommended Welding Seam in Integral Function 3 in 1 SAW H Beam Welding Machine?

1) Fabricating H Beam in the position of flat welding, or 0° welding, the proper welding seam in H Beam Fabrication Machine had better be partial penetration:

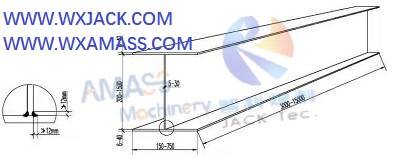

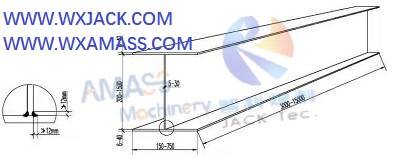

2) The design sketch on welding seam toe sizes from 3 in 1 H Beam Assembly Welding Straightening Integral Machine: (Fig.4)

D. Is Tapered H Beam Available for being Delivered from H Beam Steel Structure Fabrication Equipment ?

1. Practical Demand: During proposal exploration between customers and Wuxi JACK, many customers care on the availability of H Beam Fabrication Machine to produce tapered H Beam;

2. The feedback from Wuxi JACK is yes: 3 in 1 H Beam Fabrication Machine definitely can fabricate tapered H Beam, or in other words, variable cross section H Beam;

3. Specification: Meanwhile, the maximum slant angle should not exceed 8°. Which, in practical Steel Structure Industry, is fairly a large angular scope, and can meet most majority, or, close to 100% of customer demand on this aspect;

4. Hand made sketch on tapered H Beam, that can be produced from Wuxi JACK Integral Function 3 in 1 SAW H Beam Welding Machine: (Fig.5)

E. Summary on Wuxi JACK 3 in 1 H Beam Fabrication Machine:

1. There are really large quantity of discussions and exploration between customers and Wuxi JACK, in numerous commercial cases of H Beam Steel Structure Fabrication Equipment;

2. Such discussion is beneficial to both sides: It not only helps getting the most fitting technical solution for customers, but also inspiration source of Continuous Improvement on H Beam Assembly Welding Straightening Integral Machine;

3. Significance: As the leader on rendering the best H Beam Building and Straightening Machine for customers of so many years, such effective communication also makes great contribution, on helping Wuxi JACK maintaining our leading position on product family of 3 in 1 H Beam Fabrication Machine.