Background of This Blog on Heavy duty Automatic H Beam Production Line:

1) Customer Demand: Last week, an India customer inquired on Heavy duty H Beam Building and Straightening Machine, for producing super large size welding H Beam, which is 1.5 ~2 times of conventional biggest size of working parts;

2) Technical Communication: During negotiation, customer and Wuxi JACK had different opinion on proper structure of Heavy duty H Beam Straightening Machine, which is critical on delivering eligible straightening performance in persistent manner;

3) Technical Know How: Besides, for the other 2 core equipment in H Beam Production Line: Large Size H Beam Assembly Machine and Large Size H Beam Welding Machine, there should be also correspondingly adjustments on design of these equipment, to cater for delivering such size of “huge” H Beam;

4) Topics Covered: To have a summary on business discussion on this business case, we draft this brief blog here, as experience accumulation on steel structure equipment, for the purpose of rendering the best service to customers, with the most fitting H Beam Production Line and involved equipment:

A. The Largest Size of H Beam to be Manufactured in Heavy duty H Beam Building and Straightening Machine, and Selected Models:

1. Specification of Workpieces for the Heavy duty Automatic H Beam Production Line:

The max. dimension of H Beam presented by customer, and its comparison with conventional largest H Beam are listed as below:

1) Max. Web Height is 3000mm, compared with 1500/ 2000mm in conventional;

2) Max. Web Thickness is 60mm, compared with 32mm in conventional;

3) Max. Flange Width is 1200mm, compared with 800mm in conventional;

4) Max. Flange Thickness is 80mm, compared with 40mm in conventional;

5) Max. Weight of Single Piece is 35 Ton, compared with 10.5/ 12 Ton in conventional;

2. The models of Heavy duty H Beam Building and Straightening Machine:

Correspondingly are as below:

1) Fitting Up: Z30 Large Size H Beam Assembly Machine;

2) SAW Welding: LHC/ LHT Large Size H Beam Welding Machine;

3) Flange Flattening: YTJ-80 Heavy duty H Beam Straightening Machine.

B. Z30 Large Size H Beam Assembly Machine: Design and Workmanship:

1. Photo View: Wuxi JACK Z30 model Large Size H Beam Assembly Machine working at customer site: (Fig.1)

2. Design Change on Assembling Style in the Z30 Large Size H Beam Assembly Machine:

1) In Conventional H Beam Assembly Machine: (Fig.2)

The assembling unit works in automatic control, both sides synchronous positioning and clamping:

2) Comparatively, in this Z30 model Large Size H Beam Assembly Machine: (Fig.3)

a) The assembling driving is in the form of integrated mechanical leadscrew and hydraulic cylinder;

b) So, both heavy and reliable assembling force, as well as highly assembling precision, can be attained simultaneously;

3. Safety Measure Taken in Z30 Model Large Size H Beam Assembly Machine: (Fig.4)

1) Shown in the above photo, the most series safety hidden risk is falling down of large H Beam during assembling;

2) So, to fully guarantee safe operation in the process, and prevent the high H Beam from tipping down, there is workpiece holding brackets, assembled onto mechanical U frame gantry of the Large Size H Beam Assembly Machine;

4. Operation Arrangement and Tips on Z30 Model Large Size H Beam Assembly Machine:

1) Assembling and Fitting Up: Semi-Automatic, controlled with PLC (Programmable logic controller), and operator modulates by turning on handwheel of leadscrew;

2) CO2 GAMW Welding: Either with automatic welding power supply, or by manual labor of operator welding;

3) Labor Protection: In either welding fashion, due to the strong arc light and heavy fume emitted during CO2 welding, proper PPE (Personnel protection equipment) should be prepared and put on, including helmet/ gloves/ hard shoes:

4) Strong arc lights and fumes from CO2 in H Beam Assembly Machine: (Fig.5)

5. Requirement on Operator Qualification of the Z30 Model Large Size H Beam Assembly Machine:

To operate and manage on running of this Large Size H Beam Assembly Machine, operator should have capabilities of:

1) Assembly skill, on manual turning leadscrew during fitting on flanges with web;

2) Welding skill, for completing manual CO2 gas shield;

3) Logistics skill, to operate the large tonnages traveling crane, for hoisting workpieces to and from different positions of the Large Size H Beam Assembly Machine.

C. LHC/ LHT Large Size H Beam Welding Machine: Technique and Performance:

1. Two types of H Beam Welding Machine for building large size H Beam:

1) Required Structure: To successfully implement SAW (Submerged arc welding) on large web height H Beam, the H Beam Welding Machine should be adopted with open structure;

2) 2 Options: Correspondingly, there are 2 choices on structure of the H Beam Welding Machine, depending on specific style of the Large Size H Beam Assembly Machine:

a) When applied in automatic H Beam Production Line: This should be LHC model trolly moving H Beam Welding Machine: (Fig.6)

b) When applied in semi-automatic H Beam Production Line: This should be LHT model T frame H Beam Welding Machine: (Fig.7)

2. Technical Requirement on LHC/LHT Large Size H Beam Welding Machine:

1) Which Type of Welding? For fabricating 80mm thickness flanges with 60mm thickness web, the sizes of welding toes should be at least 60~70mm height, which is completed by means of multiple passes of large current SAW welding , in 45° fillet welding;

2) Photo View: The 45° fillet welding adopted in Wuxi JACK H Beam Welding Machine: (Fig.8)

3) Welding Complex in LHC/ LHT H Beam Welding Machine: (Fig.9)

Shown in the above photo, welding system is composed of SAW power supply, control console, welding flux recycling, and arc tracing unit.

D. YTJ80 Heavy duty H Beam Straightening Machine: Structure and Capacity:

1. So, which kind of structure is more applicable for 80mm thickness capacity Heavy duty H Beam Straightening Machine?

This is focus of controversy between Indian customer and Wuxi JACK during technical communication. Usually, there are 2 structures of hydraulic drive H Beam Straightening Machine, which has varying degree of the max. straightening capacity:

1) Wuxi JACK YTJ40/50 / 60 model Hydraulic Drive Heavy duty H Beam Straightening Machine: (Fig.10)

This series of H Beam Straightening Machine has max. straightening capacity of: 40/ 50/ 60mm flange thickness respectively, depending on specific model;

2) Wuxi JACK YTJ80 model Hydraulic Drive Heavy duty H Beam Straightening Machine: (Fig.11)

This model of H Beam Straightening Machine has max. straightening capacity of 80mm flange thickness;

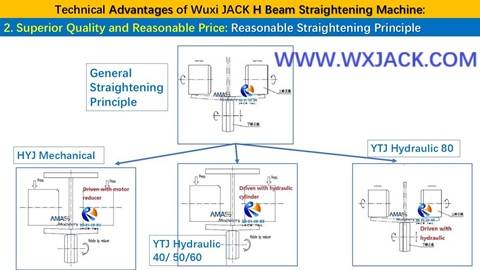

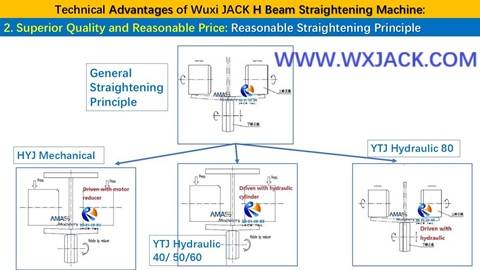

2. Straightening Illustration on 3 Major Branches of H Beam Straightening Machine: (Fig.12)

3. Technical Analysis on Straightening Capacity of 2 Types of Heavy duty H Beam Straightening Machine:

1) Although in theory, the structure of YTJ40/50/60 H Beam Straightening Machine also has theoretical straightening capacity of 80mm thickness,

2) Due to its working style of individual acting on both sides of flange,

3) The straightening unit itself is easy to go breaking, which shortens the service life of the H Beam Straightening Machine considerably,

4) And delivers unstable and feeble straightening performance on 60mm~ 80mm thickness range of H Beam;

5) This is the reason that, in this business case, Wuxi JACK recommends and insists on structure of YTJ-80 Heavy duty H Beam Straightening Machine.

E. Summary on Heavy duty Automatic H Beam Production Line:

1. Challenges: Summing up, “Quantitative change brings along qualitative change”: With the multiplying increase on workpiece specification, there are many hidden risks and operating challenges cropping up, during put into reality of Heavy duty H Beam Building and Straightening Machine;

2. Always the Best Solution: As a responsible manufacturer on H Beam Production Line and its related equipment, Wuxi JACK always seeks the most applicable technical solution for customers, considering the factors of:

1) The best technical proposal and design to guarantee quality and safety;

2) The best condition of cost effectiveness.