Subject of This Blog on 3 in 1 H Beam Assembly Welding Straightening Machine:

1) Profits for Customers: 3 in 1 H Beam Steel Fabrication Machine brings many values for customers in Steel Structure Industry, which is denoted in financial benefits of over 60% cost reduction, and over 50% productivity increase. These are real profits for customers;

2) Summary Slides: If you have interest on getting more information on this aspect, you may take several minutes to check on web page “Quick Understanding on Wuxi JACK 3 in 1 H Beam Steel Fabrication Machine”;

3) Topics in This Short Blog on Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine:

Why Such Huge Profits? In this short blog, we will have a concise explanation on working principle of this H Beam 3 in 1 Assembly Welding Straightening Machine, so that you can have quick understanding on its powerful strength, and how to make the best use of this advanced equipment:

The Role of 3 in 1 H Beam Submerged Arc Welding Machine for Steel Structure Industry;

The Working Principle of 3 in 1 H Beam Steel Fabrication Machine;

The Production Procedure of H Beam Assembly Machine with Submerged Arc Welding;

Summary on Wuxi JACK H Beam 3 in 1 Assembly Welding Straightening Machine

A. The Role of 3 in 1 H Beam Submerged Arc Welding Machine for Steel Structure Industry:

1. Why are H Beams Produced from 3 in 1 H Beam Steel Fabrication Machine so Welcomed?

1) The light to medium to heavy duty H shape steel structure working parts, named as H Beam or I Beam, have the features of quake resistance and short building duration;

2) It can increase the use location, vacuum department, stay clear of environmental pollution and sound pollution triggered by strengthened concrete work;

3) These steel structure H Beam can be reused;

4) The welding H Beam manufactured from Wuxi JACK PHJ and ZHJ series H Beam 3 in 1 Assembly Welding Straightening Machine: (Fig.1)

5) Checking from the above photo, you can find these are sintered submerged welding flux left on the finished H Beam. This is the reason, why people in this field also mention this equipment as: H Beam Submerged Arc Welding Machine with Assembly and Straightening;

2. Application Field of 3 in 1 H Beam Assembly Welding Straightening Machine:

1) H Beam is an environment friendly steel structure components, as well as remains in line with environmental management, power conserving and also lasting advancement total requirements;

2) The primary steel frame of light to medium to heavy duty steel framework includes portal steel framework as well as gable wind resistance column;

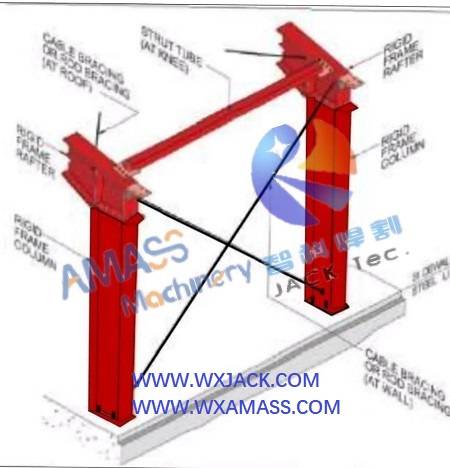

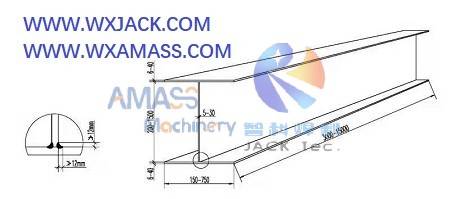

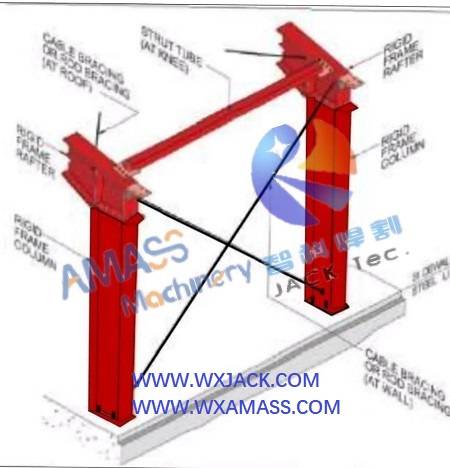

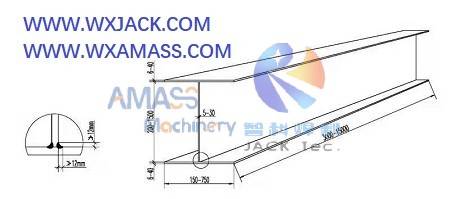

3) According to the difference of span, height and lots, the light beam and also column of portal steel framework typically take on variable cross section or uniform cross section solid internet welding H Formed area or rolled H shaped area, shown in below sketch:

4) The design steel structure frame work, constructed with H Beams from 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.2)

3. Major Steps Adopted in 3 in 1 H Beam Steel Fabrication Machine:

According to the production procedure of H Beam, the main working sequence in the 3 in 1 H Beam Submerged Arc Welding Machine can be split into:

1) Plate cutting, into flanges and web of H Beam for fabrication;

2) Setting up, Counterpart of H Beam Assembly Machine, into assembled structure of T Beam and H Beam;

3) Welding: Counterpart of H Beam Submerged Arc Welding Machine;

4) Shot blasting and also other production processes;

4. Generally speaking, the 3 in 1 H Beam Assembly Welding Straightening Machine:

1) This equipment is a crucial tool for the H Beam assembly procedure,

2) As well as it plays a definitive duty in the assurance of the H Beam Submerged Arc Welding Machine;

3) 3 steps in a row, in Wuxi JACK H Beam 3 in 1 Assembly Welding Straightening Machine: (Fig.3)

B. The Working Principle of 3 in 1 H Beam Steel Fabrication Machine:

The working principle of 3 in 1 H Beam Assembly Welding Straightening Machine is as complies with:

1. Plate Cut: The front runner ahead of it is the cutting maker to cut the steel plate into flange and web;

2. Plate Hoist: Then the flat steel plate (flanges and web) are hoisted on the input roller table of the 3 in 1 H Beam Submerged Arc Welding Machine;

3. Plate 1st Stage Assembling in the H Beam Assembly Machine with Submerged Arc Welding:

1) Following that, the assembly maker's 3 collections of securing gadgets wing plate as well as internet plate (Web) are initially secured and positioned, and the workpiece is input to the host by the energetic input roller table, completing first stage assembling in this 3 in 1 H Beam Assembly Welding Straightening Machine:

2) Hoisting and 1st Stage Assembling in Wuxi JACK 3 in 1 H Beam Steel Fabrication Machine: (Fig.4)

4. Precise Assembling, Welding and Straightening in the 3 in 1 H Beam Steel Fabrication Machine:

1) The recommended dimensions of the internet (Web) and wing plate (Flange) have actually been changed on the host;

2) As well as the workpiece can be properly located and centered in the 3 in 1 H Beam Steel Fabrication Machine;

3) Activate the automatic cycle switch, that is Head positioning place welding can be executed in the 3 in 1 H Beam Submerged Arc Welding Machine;

4) And afterwards, the H Beam that has actually been identified is separated from the Steel Fabrication Machine with a crane before getting in the following procedure;

5) Fluent production on welding H Beam in Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.5)

C. The Production Procedure of H Beam Assembly Machine with Submerged Arc Welding:

The entire H Beam production can be generally consist of the following 6 steps:

1. Prep Work of illustrations and Procedure Documents before Starting On the 3 in 1 H Beam Steel Fabrication Machine:

1) This step consists of series of standard work preparation: Numbering, cutting, putting together, welding, correcting, paint and also various other procedure files;

2) The design sketch on H Beam to be produced in 3 in 1 H Beam Submerged Arc Welding Machine: (Fig.6)

2. Typesetting and Noting for On Site Plan on the H Beam 3 in 1 Assembly Welding Straightening Machine:

1) Arrange and note the board according to the procedure file, and established a stop factor for examination;

2) Give proper training and testing on qualification of operators, inspectors, and other assistant personnel;

3. Discharging and Cutting for Raw Material Prepare ahead of the 3 in 1 H Beam Assembly Welding Straightening Machine:

1) The carbon steel plate is blanked after passing the assessment quality gate, according to the quality assessment criterion of the procedure file;

2) This step is completed by utilizing the numerical control CNC Plate Cutting Machine;

3) Customer site layout: CNC Plate Cutting Machine ahead of the 3 in 1 H Beam Steel Fabrication Machine: (Fig.7)

4. Construct Electrical Welding in the H Beam Assembly Machine with Submerged Arc Welding:

1) Start on the 3 in 1 H Beam Assembly Welding Straightening Machine by production team;

2) And have spot weld according to the needs of the procedure papers;

3) And also set a quit point for evaluation;

5. Implement SAW Welding in the 3 in 1 H Beam Submerged Arc Welding Machine:

1) Utilize the gantry moving immersed H Beam Submerged Arc Welding Machine, to execute welding after the assembly quality assessment;

2) This crucial step should be qualified according to the procedure documents;

3) The large current SAW in Wuxi JACK 3 in 1 H Beam Submerged Arc Welding Machine: (Fig.8)

6. Straightening the Up Bent Flange in H Beam 3 in 1 Assembly Welding Straightening Machine:

1) The 3 in 1 H Beam Steel Fabrication Machine is equipped with straightening unit, to straighten the welding deformation and also established a quit point for assessment, till the straightening is certified;

2) Straightening out welded H Beam in Wuxi JACK 3 in 1 H Beam Assembly Welding Straightening Machine: (Fig.9)

D. Summary on Wuxi JACK H Beam 3 in 1 Assembly Welding Straightening Machine:

1. In the year of 2009, Wuxi JACK took the lead in industry, to push into market PHJ and ZHJ series 3 in 1 H Beam Assembly Welding Straightening Machine;

2. Over the past decades, this Wuxi JACK advanced product family of 3 in 1 H Beam Steel Fabrication Machine always ranks the top grade, covering all aspects of: Design, quality, workmanship, full line of models, cost effectiveness, lead time, and after sale service.