Background of This Blog on H Beam 3 in 1 Assembly Weld Straighten Integral Machine:

1) Process Technology Planning: Planning on introducing new equipment into use is not an easy job. “Spending Money” involves series steps of decision and choice, loop by loop, which leads to fulfil outcome of rewarding running on the new equipment. This is especially true with PHJ and ZHJ series 3 in 1 Function H Beam Fabrication Machine;

2) Discussion on Wuxi JACK 3 in 1 Function SAW H Beam Welding Machine:

The entire process of purchasing and preparing on new equipment is a complicated work, which can not be deeply explored into one blog. Correspondingly, we have series of blogs discussing on this topic; 3) Subject of This Blog: Here we aim to make a summary on entire procedure of introducing Wuxi JACK 3 in 1 Function H Beam Welding Machine, connecting these pearls into a beautiful necklace. We hope these discussions can be of certain help for customers, when planning on purchasing and putting into use of the Steel Structure H Beam Fabrication Machine;

4) Topics in This Blog on Steel Structure H Beam Fabrication Machine:

a) General Steps in Selecting a Proper Model of 3 in 1 Function H Beam High Speed Welding Machine;

b) How to Find Proper Technical Proposal on H Beam 3 in 1 Fabrication Machine?

c) Technical Discussion on Details of 3 in 1 Function H Beam Fabrication Machine;

d) Planning on Layout, Installation and Utility of 3 in 1 Function SAW H Beam Welding Machine;

e) Planning on Production Details of H Beam 3 in 1 Assembly Weld Straighten Integral Machine;

f) Summary on Planning Job in 3 in 1 Function H Beam High Speed Welding Machine

A. General Steps in Selecting a Proper Model of 3 in 1 Function H Beam High Speed Welding Machine:

The headings of the middle 4 paragraphs in this blog are key words on general steps of introducing a new H Beam 3 in 1 Fabrication Machine:

1. Pick up the most appropriate technical proposal from candidate proposals;

2. Further communication on technical details of specific model of the H Beam 3 in 1 Assembly Weld Straighten Integral Machine, making it into conceptual idea;

3. Draft workshop layout on the new equipment, its installation and utility;

4. Considering concrete production preparation on daily running of the H Beam 3 in 1 Fabrication Machine.

B. How to Find Proper Technical Proposal on H Beam 3 in 1 Fabrication Machine?

This involves several steps:

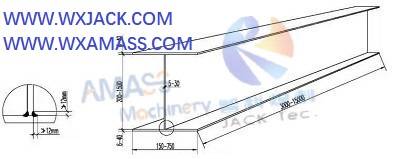

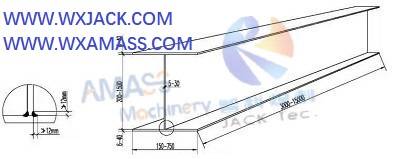

1. Clarifying on workpiece H Beam specifications ranges, to be produced in 3 in 1 Function SAW H Beam Welding Machine: (Fig.1)

2. 2 Sub Groups of H Beam High Speed Welding Machine:

1) As we know, H Beam 3 in 1 Fabrication Machine is for producing light to medium duty welding T Beam/ H Beam;

2) While H Beam Production Line is the only choice in manufacturing heavy duty H Beam;

3) When customers need to produce across boundary sizes of H Beams which do not fall into either of the Steel Structure H Beam Fabrication Machine, a tailor made proposal covering mingled equipment should be presented to customer;

3. Criterion on Judging Proper Proposal of 3 in 1 Function SAW H Beam Welding Machine:

1) Baseline: Meeting customer requirement on producing welding H Beam/ T Beam;

2) Safe operation in daily working;

3) Superior quality and high productivity;

4) Cost effectiveness;

4. In the blog “Find the Most Fitting Proposal on Producing Medium Heavy H Beam with H Beam Fabrication Machine”, we have a discussion on this topic;

5.The custom made production line composed of 2 sets of Wuxi JACK ZHJ8015 H Beam Fabrication Machine, and 90° Hydraulic Drive Overturning Equipment: (Fig.2)

C. Technical Discussion on Details of 3 in 1 Function H Beam Fabrication Machine:

1. After getting a general picture on structure and configuration of Steel Structure H Beam Fabrication Machine, next step is to explore technical details of the machine between customer and supplier;

2. Significance of This Step for Purchasing Steel Structure H Beam Fabrication Machine:

1) This is a critical step in the process. It not only helps customer acquiring the most fitting solution for their requirement, but also help Wuxi JACK maintains continuous improvement on designing our H Beam High Speed Welding Machine;

2) This step also distinguishes customer from customer on the aspect of their demand, and distinguishes Wuxi JACK from other suppliers, on our superior comprehensive capabilities;

3. Example on Technical Communication on H Beam 3 in 1 Assembly Weld Straighten Integral Machine:

1) In the blog “Some Technical Topics on Steel Structure H Beam Fabrication Machine”, we review how did Wuxi JACK engineers discuss with an overseas customer on their concerns:

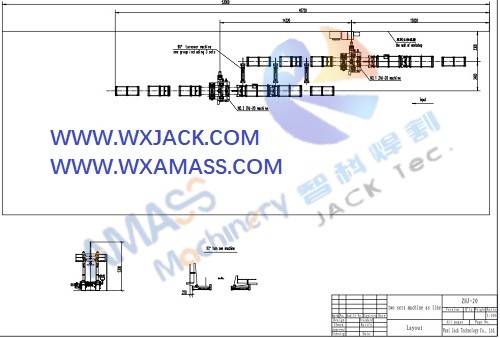

2) Is Wuxi JACK H Beam 3 in 1 Fabrication Machine capable of producing tapered H Beam? (Fig.3)

3) Does Wuxi JACK 3 in 1 Function SAW H Beam Welding Machine accommodating fully beveled welding seam? (Fig.4)

D. Planning on Layout, Installation and Utility of 3 in 1 Function SAW H Beam Welding Machine:

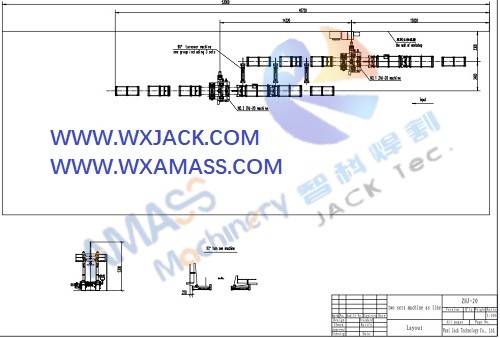

1. Now, we come to the stage of concept idea on how to locate the newly purchased H Beam 3 in 1 Fabrication Machine at customer site:

1) This involves making general layout of the Wuxi JACK 3 in 1 Function H Beam High Speed Welding Machine: (Fig.5)

2) So that customer can have an idea on what is expected workshop area on installing the machine;

3) As well as finding appropriate location of the machine;

2. Installation of Wuxi JACK PHJ and ZHJ series 3 in 1 Function H Beam Fabrication Machine:

1) This is an easy task for customers:

2) Customers do not need to make foundation ahead of time, instead, just batches of anchor bolts can secure the entire set of H Beam Fabrication Machine firmly into workshop floor;

3. Auxiliary Units on Running of H Beam 3 in 1 Assembly Weld Straighten Integral Machine:

1) Working parts H Beam has large size and heavy weight, which can not be manipulated by operator hands directly;

2) For this reason, selecting proper handling tools is of vital importance, which determines not only safe job, but also high productivity of the H Beam Fabrication Machine working;

3) Loading WIP (Work in process) T Beam into Wuxi JACK Steel Structure H Beam Fabrication Machine with traveling crane at customer site: (Fig.6)

4) Magnetic sucker for conveying and flipping workpiece H Beam ahead of 3 in 1 Function H Beam Fabrication Machine: (Fig.7)

E. Planning on Production Details of H Beam 3 in 1 Assembly Weld Straighten Integral Machine:

1. Finally, customer and supplier should make practical preparation on the on site working of H Beam High Speed Welding Machine;

2. The Check List on Production Detail in 3 in 1 Function SAW H Beam Welding Machine:

1) Welding Wire: Confirm that it is only possible to use diameter 3.2mm or 4mm welding wire. Here in Peru sometimes 2.4mm is also used and we would like to know if the H Beam High Speed Welding Machine is configured for only 3.2mm or 4mm;

2) Welding Flux: When the 3 in 1 Function H Beam Welding Machine is adopted with SAW (Submerged arc welding), which account for over 95% applicating scenario, SJ101 sintered flux is recommended;

3) Electricity: One set of PHJ and ZHJ model H Beam 3 in 1 Assembly Weld Straighten Integral Machine takes electricity capacity of around 180KVA;

4) Production Cost: In the blog “How Much and How Long to Produce a Piece of H Beam in Wuxi JACK H Beam Fabrication Machine”, we calculated in detail on this issue.

F. Summary on Planning Job for 3 in 1 Function H Beam High Speed Welding Machine:

1. Qualification: To successfully introducing new equipment, involves broad professional knowledge, covering mechanical/ electric/ hydraulic/ welding technology background, together with financial skills, production experience, etc.;

2. Wuxi JACK Leading Edge: Relying on accumulation on numerous business cases on H Beam 3 in 1 Fabrication Machine over the past decades, Wuxi JACK has amassed rich experience on Order to Delivery of this important equipment of Steel Structure H Beam Fabrication Machine, and more than willing to share with customers worldwide.