The Subject of This Blog on Welding Positioner:

1) Importance: Welding Positioner is a kind of very important Welding Equipment, which is widely used across industries for fabricating on different kinds of workpieces;

2) Specialty: Because of such diversified structures of workpiece, and correspondingly diversified customer requirement on position change, Welding Positioner and its Welding Turning Table comes in wide variety of structures/ functions/ configurations/ operations, which test the capability of supplier on designing and developing to meet customer demand;

3) Subject: This short blog will give a summary on common seen categories of Welding Positioner and its Rotary Welding Table in use, so that customers can have a quick decision on the proper type of the welding equipment to choose from:

Usage and Application

Classification and Models

Technical Function Views

A. Usage and Application of Welding Positioner / Rotary Welding Table:

1. Function: Welding Positioner changes workpiece position in the form of:

1) 0° ~ 360° infinite rotation;

2) 0° ~ 120° tilting;

3) Up and down movement;

4) Horizontal moving;

To attain optimum position of structure members secured on Welding Positioner, so as to implement on welding with ideal ergonomics position, and guarantee on the best welding quality;

2. Welding Center Integrated with Other Welding Equipment:

In practical application, Welding Positioner either works individually, or with other Welding Equipment, especially Welding Rotator, as well as Column and Boom Automatic Welding Equipment, to be formed into tailor made Welding Center, fulfilling on complicated welding tasks for customers;

3. Applicative Industry of Welding Positioner and its Welding Turning Table:

As a kind of extensively applied necessary Welding Equipment where structure members to be fabricated: In the industries of Construction Machinery, Vehicle, Engineering Machinery, sees broad use of different types of this welding positioning equipment.

B. Classification and Main Specifications of Welding Positioner and its Rotary Welding Table:

In practical use, this comes into 6 broad categories of:

1) Two Degrees of Freedom for its Rotary Welding Table:

a) 0° ~ 360° infinite rotation;

b) 0° ~ 120° tilting;

c) Applicable for fabricating on small size structure members;

2) Loading capacity of its Rotary Welding Table is from 100kg to 30 Ton;

3) Variation of Two Axis Conventional Welding Positioner:

On the basis of standard structure and function,

a) Work table elevating function: The 3rd axis degrees of freedom: (Fig.2)

b) Servo motor drive and encoder control for accomplishing high precision position management;

c) Special Rotary Welding Table with special welding fixture, for special workpieces;

d) Double sets of Rotary Welding Table, which are positioned independently from each other, and can have its interval adjusted, based on length of the workpieces connected through: (Fig.3)

1) Two degrees of freedom for Its Welding Turning Table:

a) 0° ~ 360° infinite rotation;

b) 0° ~ 360° tilting in the air;

c) The 3rd Axis: Rotary Welding Table and workpiece elevation;

d) Applicable for fabricating on larger size structure members;

2) Loading capacity of its Rotary Welding Table is from several hundred kg to 4 Ton;

3. HTHB Series Two/ Three/ Four Motion Axis Head and Tail Welding Positioner: (Fig.5)

1) Two ~ Four Degrees of Freedom for its Welding Turning Table:

a) Workpiece elevation;

b) 0° ~ 360° tilting in the air;

c) Optional the 3rd axis degree of freedom: 0° ~ 360° infinite rotation in the air;

d) Headstock (The first upright column) is stationary, and tailstock (The second column) is movable along workshop floor, catering on length of workpieces;

e) Applicable for fabricating on long length structure members;

2) Two types of Mechanical Structures in Head and Tail Elevating Welding Positioner:

a) Both sets of upright columns, which are headstock and tailstock of the Welding Positioner, are all fixed style into workshop floor;

b) One set of column is fixed (Headstock), and the other set can be moved along rails (Tailstock), based on length of workpiece fit through;

3) Loading capacity of Elevating Head and Tail Welding Positioner is from several hundred kg to 20 Ton;

4. SAHT Series Single Axis Horizontal Welding Turning Table: (Fig.6)

1) Loading capacity of its Rotary Welding Table is from several hundred kilograms to 30 Ton;

2) When installed with servo motor drive, loading capacity of its Rotary Welding Table is up to 3 Ton;

3) Applicable for fabricating on circumferential seams on large size structure members;

5. SHB Series Single Axis Vertical Welding Positioner: (Fig.7)

1) Its rotary welding table is assembled in upright vertical orientation;

2) Loading capacity of its Welding Turning Table is up to 5 Ton;

3) Applicable for fabricating on circumferential seams on small size structure members;

6. PR Series Special Design Pipe Welding Rotator: (Fig.8)

Two Degrees of Freedom for its Rotary Welding Table:

1) 0° ~ 360° infinite rotation;

2) -45° ~ 45° tilting in the air;

3) Applicable for fabricating on Pipe Flange Assembly and or Pipe Elbow Assembly.

C. Technical Function Views on Welding Positioner and its Welding Turning Table:

1. Safety Assurance on Rotary Welding Table Revolving, Tilting and Elevation:

Safety is the first issue which should be considered and guaranteed for developing any kind Welding Positioner. For this purpose, in Wuxi JACK products:

1) Drive motors of rotary welding table and workpiece for revolve and tilt are all braking type;

2) For Wuxi JACK Elevating L type Welding Positioner, hydraulic oil cylinders are adopted for driving elevation of its rotary welding table and workpiece, instead of ordinary motors selected by some other suppliers. As shown in below photo: (Fig.9)

3) There are hard stops equipped in all motions of rotary welding table: Revolving, Tilting and Elevation;

2. Conveniently and Precisely Adjustable Welding Speed of Welding Positioner:

1) Revolving linear velocity of Welding Turning Table is welding speed in all categories of Welding Positioner;

2) This adjustable working speed is controlled with A.C. inverter, to realize stepless continuous change, and displayed in digital display meter;

3) Adjustment on welding speed is convenient: Just turn the speed knob on the operating pendant of Welding Positioner, which is installed along side the digital display meter: (Fig.10)

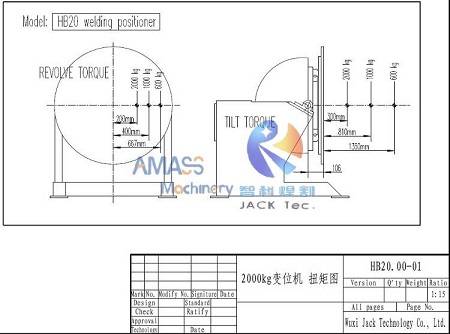

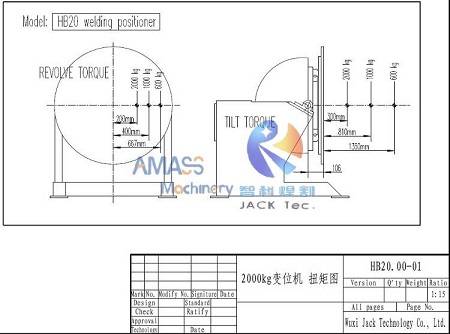

3. Gravity Center Distance and Eccentric Center Distance in Welding Positioner: (Fig.11)

1) This is one of the core technical issues in developing all types of Welding Positioner product;

2) These 2 parameters determine reliability of Welding Positioner and its Welding Turning Table performance, and should be calculated and validated carefully during NPI (New product introduction).