Background and Subject of This Press News on Wuxi JACK Line of H Beam Welding Production Machine:

1) Prosperous Business:

In February of 2025, when majority of Chinese people still not return to normal working state from the joy of celebrating Spring Festival, Wuxi JACK team has already devote every effort, to fulfil large orders on Line of H Beam Welding Production Machine from many overseas customers, which are expected to be completed and delivered gradually by end of May 2025;

2) Topic of This News Release on H Beam Welding Production Machine:

These business orders are all featured and advantageous products of Wuxi JACK, which worths discussion here a bit:

Brief Introduction on Orders of Wuxi JACK H Beam Welding Production Machine;

Wuxi JACK Heavy duty Line of H Beam Welding Production Machine;

Wuxi JACK Heavy duty H Beam Hydraulic Straightening Machine;

A. Brief Introduction on Orders of Wuxi JACK H Beam Welding Production Machine:

In sequence of placing order, these orders include:

1. Automatic Line of H Beam Welding Production Machine:

1) Customer: A Russian steel structure company;

2) Characteristic: This is the largest order in these business cases, in terms of:

a) Contract value;

b) Specifications of finished H Beam (Model: HB2000);

c) Quantity of machines in the production line:

3) The expected finished automatic H Beam Welding Production Line (Reference photo of the previous order several years ago, also for a Russian customer. This time the model of line is bigger) (Fig.1):

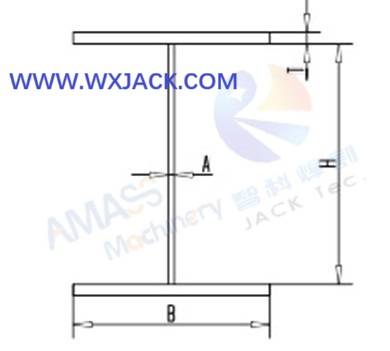

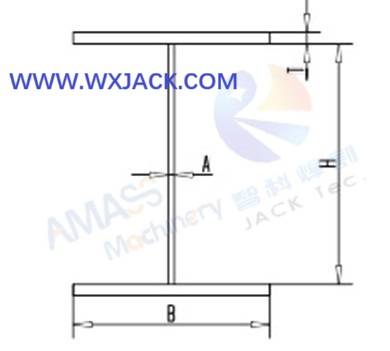

4) Task: To produce large welded H Beam with specifications as below (Fig.2):

a) H Beam Wall (Web) Height H: 150 ~ 2,000 mm;

b) H Beam Wall (Web) Thickness A: 10 ~ 70 mm;

c) H Beam Shelf (Flange) Width B: 200 ~ 800 mm;

d) H Beam Shelf (Flange) Thickness T: 6 ~ 80 mm;

2. SXBJ-14 Large Double Heads Edge Milling Machine:

1) Customer: A Russian customer from Novosibirsk pressure vessel company;

2) Task: To cut out various common seen and special bevels, on top/ straight/ bottom edges of carbon steel plate, with the max. sizes of: Length 14m, width 2,500mm/ thickness 100mm:

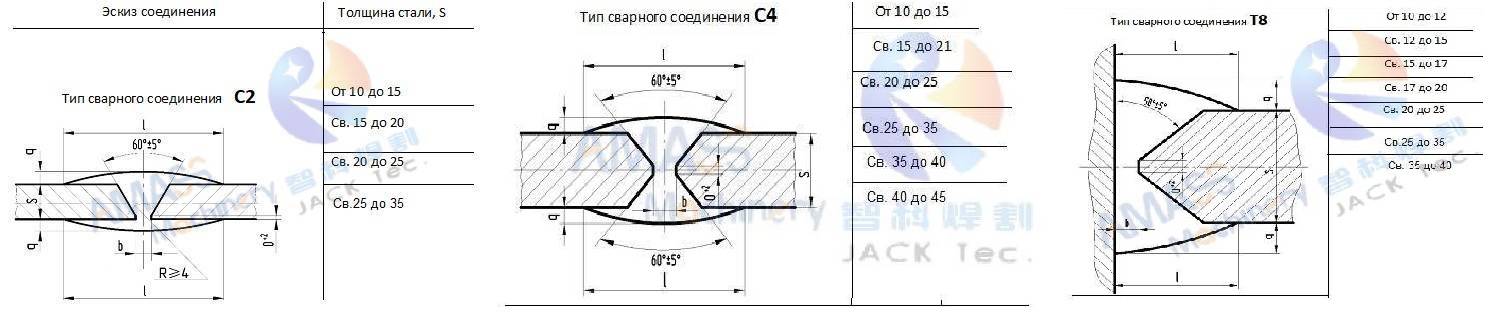

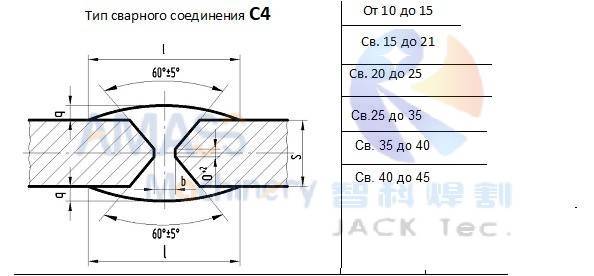

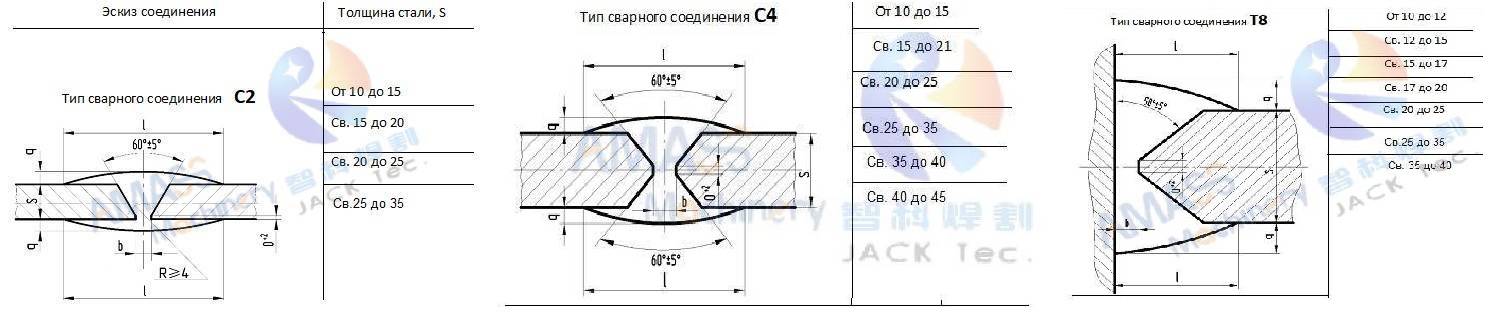

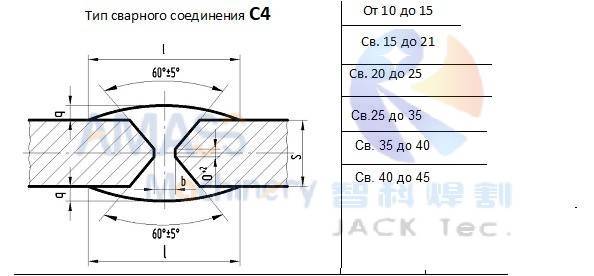

3) Examples of typical welding grooves from the machine: (Fig.3)

4) The expected appearance of Wuxi JACK SXBJ-14 Large Double Heads Edge Milling Machine (Taken at another Russian customer facility, on the same model, several years ago): (Fig.4)

3. SXBJ-3 Small Double Heads Edge Milling Machine:

1) Customer: A Vietnam dealer of long term relationship with Wuxi JACK;

2) Technical Feature: This is the smallest model of Double Heads Edge Milling Machine, but with complete configuration (Milling head, other function units), and identical level of technical complication;

3) Task: To mill out finished grooves on up/ straight/ lower edges of sheet metal, with the max. sizes of: Length 3,000mm/ Width 2,000mm/ Thickness 40mm;

4) The classical grooves cut from Wuxi JACK SXBJ-3 Double Heads Edge Milling Machine: (Fig.5)

5) The expected appearance of Wuxi JACK SXBJ-3 (Taken on the same model of machine, at another customer before): (Fig.6)

1) Customer: The same Russian steel structure company, who purchases the heavy duty Line of H Beam Welding Production Machine, listed in the first item;

2) Technical Feature: Belongs to medium level heavy duty equipment for H Beam flange straightening, in terms of straightening force, and hence straightening capability;

3) Task: To high efficiently straighten out deformed flange (shelf) of welded H Beam, fabricated from H Beam SAW Welding Machine, with H Beam flange (shelf) thickness up to 60mm, for H Beam material of Q345 carbon steel, equals to tensile strength of 570~ 610 MPa;

4) The expected appearance and running moment of Wuxi JACK YTJ-60 (Taken at a Chinese steel structure client workshop, on the same model of the Wuxi JACK product, delivered before): (Fig.7)

5. YTJ50 Model H Beam Hydraulic Straightening Machine:

1) Customer: A Chinese foreign trade company. Country of end user unknown;

2) Technical Features and Task: Nearly the same as the previous introduced YTJ60 model. The only difference is the max. thickness of H Beam flange (Shelf) that can be straightened: 50mm;

3) The expected appearance and working site of Wuxi JACK YTJ50 (Taken at a Chinese steel structure customer group years ago): (Fig.8)

1) Customer: A Belarus service company;

2) Task: To have end face milling on H Beam and other steel structure workpieces, especially BOX Beam, Cross Beam... The max. end face milling stroke: Height 1,500mm by width 2,000mm;

3) Technical Characteristic: This is the “standard” model with the largest selling volume of its product family, meeting requirement on majority of requirement;

4) The expected appearance of Wuxi JACK DX1520 H Beam End Face Milling Machine, works at customer site: (Fig.9)

Below is one by one brief introduction on each of the business orders from different customers we are striving now:

B. Wuxi JACK Heavy duty Line of H Beam Welding Production Machine:

1. Nature: This includes numerous sets of machines, being arranged at different working stations of the line, for fulfilling on related task at each process step;

2. The Equipment in Heavy duty Line of H Beam Welding Production Machine:

For this time contract, in sequence of H Beam production, and its task respectively:

1) Z20 H Beam Assembly and Stitch Welding Machine, 1 set:

a) Task: As the 1st key step in the process of welded H Beam production, this machine is for fitting up flange (shelf) and web (wall) into first assembled T Beam, and then assembled H Beam, and have CO2 spot welding at the same time, to strengthen the assembled H Beam;

b) Wuxi JACK Z20 H Beam Assembly and Stitch Welding Machine works at customer workshop: (Fig.10)

2) LHC H Beam SAW Welding Machine, 4 sets: (Fig.11)

a) Task: To have SAW (Submerged arc welding) on assembled H Beam, in the position of 45° fillet welding. There are 4 pieces of welding seam that need to be fabricated in one piece of H Beam. Correspondingly, there are 4 sets of LHC in a H Beam Welding Production Line, one set of LHC responsible for welding one piece of seam:

b) The 4 sets of Wuxi JACK LHC run simultaneously at automatic line of H Beam production: (Fig.12)

3) YTJ-80 Heavy duty H Beam Hydraulic Straightening Machine, 1 set:

a) Task: To flatten out upward deformed flange (Shelf) of H Beam after SAW station. YTJ-80 is the largest model of its product family, that this model can straighten on H Beam flange of 80mm thickness, made of Q345 carbon steel;

b) Close view on working moment of Wuxi JACK YTJ-80 H Beam Hydraulic Straightening Machine, at end of line for H Beam production: (Fig.13)

4) 60°/ 90°/ 180° H Beam Hydraulic Overturning Machine, 7 groups in total in a line:

a) Task: At different stations of Line of H Beam Welding Production Machine, based on requirement on process technology, the workpiece H Beam need to be flipped certain angle to the optimum angular orientation, so as to have the ideal welding performance and efficiency:

i. H Beam Assembly station: 90° overturning, 1 group;

ii. H Beam SAW Welding station: 60° overturning, 4 groups;

iii. H Beam flange Straightening station: 180° overturning, 2 group;

b) Wuxi JACK 60° H Beam Hydraulic Overturning Machine at LHC station: (Fig.14)

C. Wuxi JACK Heavy duty H Beam Hydraulic Straightening Machine:

1. Why We Discuss Here on the Machine:

As can be found from the above introduction, in these business contracts introduced here, there are 3 sets of different models of H Beam Hydraulic Straightening Machine requested by different clients: YTJ-80, YTJ-60, YTJ-50, either as part of the H Beam Welding Production Line, or as individual running machine. This demonstrates on wide requirement on this machine, and the popularity of our product;

2. Technical Superiorities of Wuxi JACK H Beam Hydraulic Straightening Machine:

1) Adopt the Most Proper Straightening Principle: Wuxi JACK has different design on the machine, to provide the most fitting design for customers, in terms of quality and efficiency:

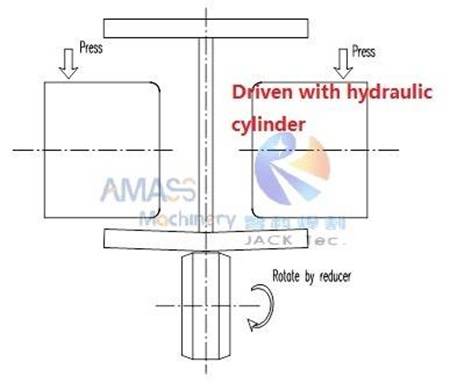

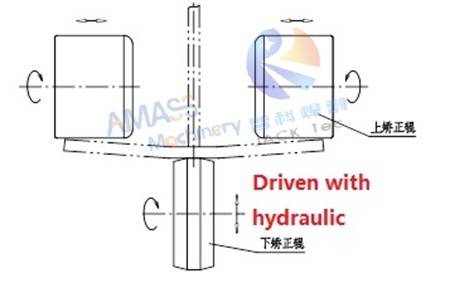

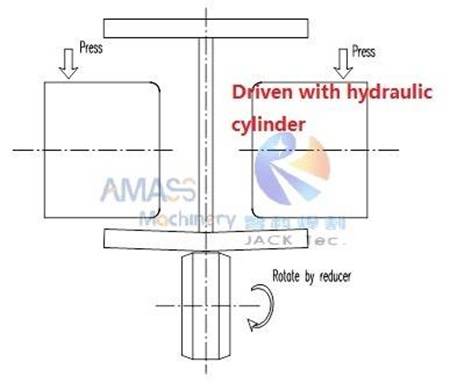

a) Work theory of Wuxi JACK YTJ-40 and YTJ-50: (Fig.15)

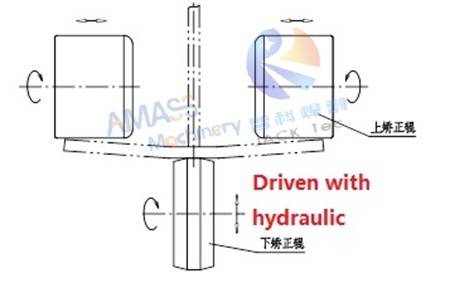

b) Work theory of Wuxi JACK YTJ-60 and YTJ-80: (Fig.16)

2) Solid Structure and Heavy Straightening Force, to deliver sufficient straightening effect with fair margin:

Operator works on Wuxi JACK YTJ-80, to straighten on heavy welded H Beam: (Fig.17)

3) Wuxi JACK Exclusively Product Series of Longitudinal Direction H Beam Hydraulic Straightening Machine:

Besides the mainstream models of the machine for H Beam flange (Shelf) straightening, Wuxi JACK also owns the uniquely series of the machine, developed for longitudinal direction H Beam straightening, this greatly enhances competitiveness of our equipment:

a) The longitudinal distorted welded H Beam: (Fig.18)

b) Wuxi JACK HJ300 model longitudinal H Beam Hydraulic Straightening Machine works at customer facility: (Fig.19)

D. Wuxi JACK Large Double Heads Edge Milling Machine:

1. Why Discuss the Machine Here:

1)This is one of the most competitive products of our company with leading edges. It is very popular in the market, especially among overseas customer. Our machines have series of uniquely owned technical advantages, which distinguish our machines from others suppliers. In other words, we take the lead in supplying high end models for customers:

2) The superior quality beveled carbon steel plate, cut from Wuxi JACK Double Heads Edge Milling Machine: (Fig.20)

2. Technical Advantages of Wuxi JACK Double Heads Edge Milling Machine:

These are functions and capability that only you can find from our Edge Milling Machine, not any other producers:

1) Hydraulic drive steel plate loading and unloading brackets, liberating operators from dangerous and toilful task of plate handling: (Fig.21)

2) HMI (Human machine interface), for intuitively/ convenient and easily keying in and controlling finished beveling angle: (Fig.22)

3) Top grade milling head of high power 7.5Kw/ 9.3Kw/ 11kW, capable of delivering any conventional or special range of milling angle: 0° ~ 45°/ 0° ~ 90°/ -45° ~ 45°... (Fig.23)

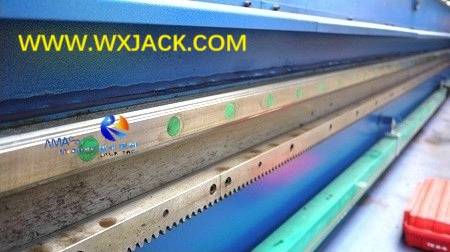

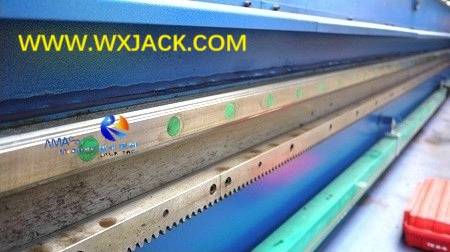

4) Heavy duty precise linear guiderail, for smoothly and stably guiding movement of milling head along machine bed (edge of steel plate), so as to deliver superior and consistent edge milling performance: (Fig.24)

5) Counter for controlling feeding stroke of milling head carriage motor, for precisely controlling milling cutting depth: (Fig.25)

E. Wuxi JACK H Beam Hydraulic Overturning Machine:

1. Why Discuss This Machine Here:

1) As supporting role for H Beam production, these overturning equipment play critical role in automatic line for H Beam production, especially heavy duty automatic line: Just suppose how heavy (Up to 20 tons) and large dimension (Up to 2,000mm height) of these welded H Beam workpieces, which are very dangerous and difficult to be handled by human labor, you can imagine the great effect of H Beam Hydraulic Overturning Machine:

2) Wuxi JACK stationary 60° H Beam Hydraulic Overturning Machine works at automatic Production Line: (Fig.26)

2. Major Types of Wuxi JACK H Beam Hydraulic Overturning Machine:

1) In terms of moving or not: Either stationary, or motor drive movable;

2) In terms of the Max. overturning angle: 60°/ 90°/ 180°:

Wuxi JACK movable 180° H Beam Hydraulic Overturning Machine: (Fig.27)

3) In terms of Structure:

a) Besides the conventional hard overturning arm (Rack) type, there are also soft chain type:

b) Wuxi JACK chain type overturning machine for flipping H Beam: (Fig.28)

4) In terms of Applicable Workpieces:

a) Besides the most widely used H Beam Hydraulic Overturning Machine, this type of flipping equipment can also be used for handling any other types of steel structure workpiece: Large steel plate/ BOX Beam/ Structural workpieces:

b) Wuxi JACK chain type Overturning Machine for flipping BOX Beam works at customer workshop: (Fig.29)

F. Wuxi JACK H Beam End Face Milling Machine:

1. Why We Discuss This Machine Here:

Definitely, this machine is one of the most popular product equipment of Wuxi JACK, and has the largest selling volume. Every year, we produce and delivery over 50 sets of this machine of different models for steel structure customers, especially in export business;

2. Function:

a) This machine can not only machine on conventional steel structure workpieces: H Beam/ BOX Beam/ Cross Beam... But also those “special” types: Pipes/ structure parts:

b) Typical workpieces of conventional models H Beam End Face Milling Machine: (Fig.30)

3. Technical Superiorities of Wuxi JACK H Beam End Face Milling Machine:

Same as Edge Milling Machine, Wuxi JACK produced machine for end face milling also has series of unique functions, which distinguish our products in the market, and gained wide popularity from customers:

1) CNC Control H Beam End Face Milling Machine:

a) This helps the machine capable of machining on any type of workpieces: (Fig.31)

b) Wuxi JACK CNC-DX3030 works at steel structure customer site: (Fig.32)

2) Complete Line of Models, catering for all sizes of workpieces:

a) This covers the scope from the smallest model DX08xx (The max. milling height of the machine is 800mm), to the largest model DX60xx (The max. milling height of 6,000mm)

b) Wuxi JACK DX0815 small model ready for shipment: (Fig.33)

c) Wuxi JACK DX6080 large model operates at Vietnam customer site: (Fig.34)

3) Heavy duty Precise Linear Guiderail:

a) Being assembled onto upright column and horizontal machine bed, for smoothly guiding movement of milling head in both directions, thus guarantee on stable and top grade milling performance:

b) HIWIN guiderail on every model of Wuxi JACK H Beam End Face Milling Machine: (Fig.35)

4) High Power Milling Head of Superior Performance:

a) As core function unit of H Beam End Face Milling Machine, the milling head of Wuxi JACK machines all have high power (7.5Kw/ 9.3Kw), with exceeding functions, especially milling performance and way of spindle revolutionary linear speed change:

b) The 7.5kW milling head in Wuxi JACK H Beam End Face Milling Machine: (Fig.36)

We will provide follow up report on progress of these contracts on Wuxi JACK Line of H Beam Welding Production Machine, in the next months of first half year of 2025.