Background of This Article on SXBJ-6 Advanced Functional Double Heads Edge Milling Machine:

1. Wuxi JACK Exceeding Business Achievement on Edge Milling Machine:

1) Business Case: In Nov. 2024, a set of SXBJ-6 model Double Heads Plate Edge Milling Machine will be shipped to Russia by Wuxi JACK. Currently, the machine is in the stage of final testing on its operation and performance, and will be prime and final painted as the last step of machine production;

2) Large Volume: This is the 10th set of XBJ series Sheet Metal Edge Milling Machine Wuxi JACK exported in the year of 2024, and around the 240th set since the year of 2009;

2. Topics of This Blog on SXBJ-6 Advanced Functional Edge Milling Machine:

Usage and Advanced Configuration of SXBJ-6;

Technical Characteristics of SXBJ-6;

Main Component Lists and Technical Feature of SXBJ-6;

Technical Introduction on Main Units of SXBJ-6;

Summary on Wuxi JACK Plate Edge Milling Machine

A. Usage and Advanced Configuration of SXBJ-6 Advanced Functional Edge Milling Machine:

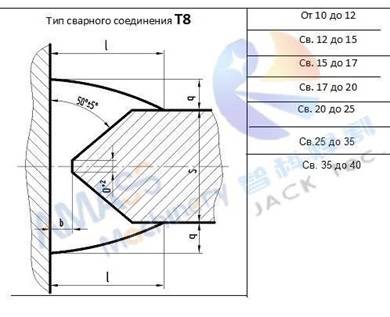

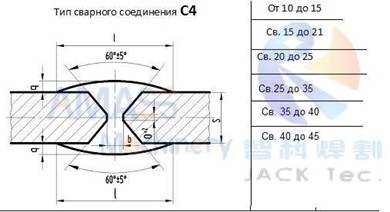

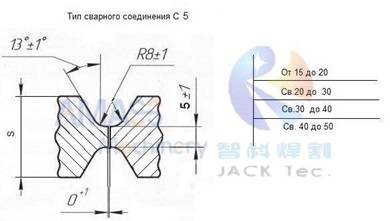

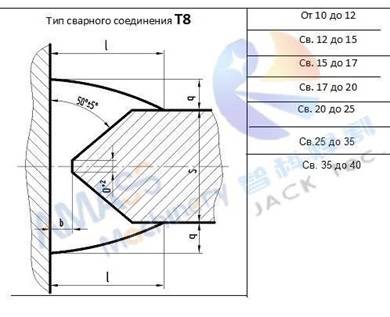

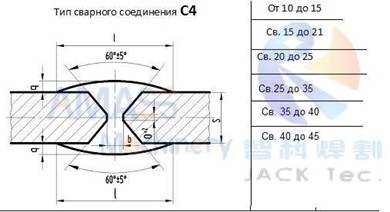

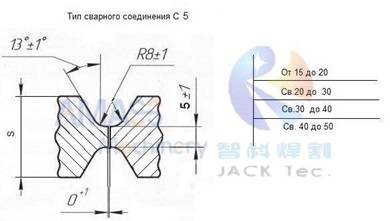

1. Function: This machine is used for sheet metal plates edge processing after thermal cutting, and preparing on the edges for welding. The machine allows to process, depending on mill blade type and shape, into finished V type edge milling groove, X type edge milling groove, and U type edge milling groove:

1) V (K) type edge milling groove: (Fig.1)

2) X type edge milling groove: (Fig.2)

3) U type edge milling groove: (Fig.3)

2. High End Components Equipped in SXBJ-6 Advanced Functional Sheet Metal Edge Milling Machine:

i. The customer of this machine is long term established partner of Wuxi JACK, a renowned machine tools distributor in Russia. Over the past 2 decades, this Russia customer has popularizing Wuxi JACK superior quality machine tools, including:

1) Edge Milling Machine;

2) PHJ and ZHJ series 3 in 1 H Beam Fabrication Machine;

3) DX series Steel Structure Beam End Face Milling Machine;

And other steel structure machine tools, Welding and Cutting Machineries in Russia and other CIS countries. Wuxi JACK produced superior quality machineries and equipment have gained extensive word of mouth at these markets;

ii. This set of SXBJ-6 Double Heads Plate Edge Milling Machine is equipped with numerous function components which take leads in industry. Some are even Wuxi JACK exclusive equipped units. For example:

1) HMI (Human machine interface) to precisely manage on and real time display on edge milling angle: (Fig.4)

2) Hydraulic drive roller tables, for automatically pushing and pulling steel plate into and out of edge milling work table of Edge Milling Machine: (Fig.5)

3) Taiwan produced E-LONG brand high power 11 kW milling head, delivering top grade edge milling efficiency and quality: (Fig.6)

B. Technical Characteristics of SXBJ-6 Double Heads Plate Edge Milling Machine:

Below is value on major technical parameters of this SXBJ-6 model Advanced Functional Plate Edge Milling Machine, confirmed between Russian customer and Wuxi JACK engineering team:

Plate thickness processing range | 6 ~ 40 mm |

Plate maximum processing zone length | 6000 mm |

Plate maximum processing width | 2500 mm |

Plate maximum weight | 10 tons |

Milling accuracy | Bevel processing accuracy | ± 1° |

Finished surface roughness grade | ≤ 6,3 |

Milling head | Model | ELONG MU-6S (Taiwan) |

Quantity of milling units | 2 pieces |

Milling head power | 11 kW |

Milling head turning | Type | Motor drive, controlled with encoder |

Turn control | With individual control panel, rotation step 0.1° |

Milling head rotation angle | Milling unit No. 1, 2 | -45°... +45° (Groove angle scope) |

Working zone lighting in Edge Milling Machine | Local lighting on each milling head |

C. Main Component Lists and Technical Features of SXBJ-6 Double Heads Sheet Metal Edge Milling Machine:

Below is brief description on raw material/ specifications of main units of the Edge Milling Machine:

|

|

Milling head | E-long MU-6S, made in Taiwan, 2 pcs |

Milling cutter | GMA200 model, Chinese famous brand |

Linear guides of horizontal movement, X axis | HIWIN guide CG45, made in Taiwan |

Down guide rail of milling heads horizontal and vertical movement, X, Y axis | Carbon steel #45, tempered, surface hardness HRC48-52 |

A.C. Inverters for controlling milling head along X, Y axis | Mitsubishi, 2 pcs |

Hydraulic components (Oil pipe, pump station, electromagnetic control valves) | Chinese famous brand |

X axis electric motor | 2.2kW, made in Taiwan |

Y axis electric motor | 1.1kW, Chinese famous brand |

Electric components | Siemens |

Down guide rail dust protection | 2 stages dust scraping unit |

Lubrication system for X and Y axis guides | Automatic lubrication system |

Hydraulic feeding system | 2 feeding speeds – fast and slow |

Mill cutter cover | Metal protective cover |

Safety icons in Edge Milling Machine | Striking safety icon conforms to international standard |

Electric cabinet of milling unit | Independent for each unit, with vibration dampers |

Operator panels | Russian language captions |

D. Technical Introduction on Main Units of SXBJ-6 Advanced Functional Plate Edge Milling Machine:

1. Overall Structure of SXBJ-6 Sheet Metal Edge Milling Machine:

1) Machine bed is of welding structure, which is destressed through high temperature temper. Linear guides, gear rack and guide rail are placed on the machine bed. To ensure sufficient lubrication of guides automatic lubrication system is used. On the upper beam hydraulic jacks are installed:

2) The final assembled mechanical main frame of SXBJ-6 before painting, at Wuxi JACK workshop: (Fig.7)

2. The 2 Milling Units of SXBJ-6 Double Heads Sheet Metal Edge Milling Machine:

1) The upright erected milling column is being fixed on movable platform, which is driven with handwheel, screw gear and reducer, to control on movement along Z axis counter scale is used;

2) Column fixation to horizontal movement platform is made with use of adjustment pins, for strong fixation of its position, to exclude possibility of incorrect installation;

3) Assembled milling unit: Milling column and movable platform onto worktable of SXBJ-6 Plate Edge Milling Machine: (Fig.8)

3. Hydraulic System of SXBJ-6 Double Heads Plate Edge Milling Machine:

1) Function: Hydraulic system is used for firmly clamping the workpiece (Carbon steel plate) during processing with hydraulic cylinders, and workpiece feeding into processing zone with hydraulic push devices and lifting sections;

2) Performance Guarantee: To ensure constant clamping pressure during edge milling operation, hydraulic station must be equipped with hydraulic locks. Hydraulic station shall be equipped with hydraulic accumulator; To provide speed changing of hydraulic push devices feeding, hydraulic station shall be equipped with extra valve;

3) Oil pipelines distributed along up gantry beam of SXBJ-6 Double Heads Plate Edge Milling Machine: (Fig.9)

4. Electric Control System of SXBJ-6 Double Heads Sheet Metal Edge Milling Machine:

1) Milling head drive load indicator (A meter) is installed on control panel or on milling heads, and motor protect against overcurrent is installed in control box of the Edge Milling Machine;

2) All electric components of each milling unit should be installed into the independent electric cabinet, fixed on the side of milling units’ column through vibration dampers;

3) Superior Quality: All electric control components of the machine: A.C. relay, breaker, contactors... are Siemens brand.

E. Summary on Wuxi JACK Plate Edge Milling Machine:

1. Wuxi JACK Achievement on Sheet Metal Edge Milling Machine:

XBJ series Edge Milling Machine is featured product of Wuxi JACK;

1) There are only a few Chinese companies in industry, which can design and produce high standard machines for processing on grooves on edges of sheet metal plates, and Wuxi JACK is one of the leading professional companies on producing different designs superior quality Edge Milling Machine, with rich experience;

2) Over the past 2 decades, Wuxi JACK has successfully developed and delivered over 240 sets of Edge Milling Machine, in various models/ specifications/ sizes, for customers in China and overseas market;

2. The Technical Characteristics of Edge Milling Machine:

Can be summarized as:

a) Complicated structure, which poses great challenge on designer of the machine;

b) Wide variety of configuration: Single, double, four, five milling heads, to cover broad scope of edge milling application requirement from customers;

c) Difficulty in Manufacture: There are over hundreds of pieces of components of different sizes/ structures to be assembled into a set of Edge Milling Machine. The process technology on production on the entire machine:

1) From 1st cutting and machining on mechanical components;

2) To fabrication (welding) on sub-assemblies;

3) To heat treatment on welded sub-assemblies;

4) To assemble sub-assemblies into final assembly of overall mechanical main frame of Edge Milling Machine;

5) To electric cable routing of electric control system;

6) To oil hose disposition of hydraulic system;

7) To validation on Edge Milling Machine performance;

8) To prime and finished painting;

9) To final shipment of machine...

All poses many control points, which tests on comprehensive strength of manufacturer of Plate Edge Milling Machine;

3. Main Branches of Wuxi JACK Plate Edge Milling Machine:

Wuxi JACK products of machinery for edge milling can be grouped into 3 series of:

1) General purpose single and double heads Edge Milling Machine;

2) Double Heads Edge Milling Machine;

3) Advanced Functional Edge Milling Machine;

These rich assortment of machine models can provide the most fitting solution for customers on milling out grooves on sheet metal plates.