Background of This Blog on H Beam Steel Structure Fabrication Machine:

1) Business Acumen: Entering the year of 2023, there are numerous customers from different countries, having demand on producing H Beam in diversified specifications;

2) Assortment of Equipment: In Steel Structure Equipment Industry, there are different kinds of H Beam Fabrication Machine, including H Beam Welding Machine, H Beam Production Line, H Beam Assembly Weld Straighten Integral Machine... Which has its specified realm of applicable workpieces H Beam for manufacture;

3) Expect On Tailor Made Solution Steel Structure H Beam Fabrication Machine:

a) Of course, it is easy to recommend corresponding Steel Structure Fabrication Machine for customers, suppose working parts falling perfectly into specification range of the corresponding equipment;

b) However, in practical application, conditions are so simple: Customers need to produce working parts H Beam with extensive and personalized specifications;

c) Under such conditions, finding the most fitting technical proposal of H Beam Assembly Welding Straightening Integral Machine seems of vital importance;

4) Topics Covered in this short blog on Integral Function H Beam Welding Machine:

Let us have brief discussion on below topics:

a) Default Specifications of Wuxi JACK H Beam Assembly Welding Straightening Integral Machine;

b) Recommended Equipment for Welding Thick H Beam: SAW H Beam Welding Machine;

c) Solution on Producing 12mm Leg Size with Wuxi JACK 3 in 1 H Beam Fabrication Machine;

d) Straightening Capability in Wuxi JACK H Beam Assembly Weld Straighten Integral Machine;

e) Advantages of Wuxi JACK Integral Function H Beam Welding Machine;

f) Business Case Example on Wuxi JACK Steel Structure H Beam Fabrication Machine

A. Default Specifications of Wuxi JACK H Beam Assembly Welding Straightening Integral Machine:

1. For producing welding H Beam with flange (Wings) thickness equals to 25mm or less, the PHJ and ZHJ series Steel Structure H Beam Fabrication Machine is perfect choice;

2. Demonstrated in below sketch, Wuxi JACK 3 in 1 H Beam Welding Machine covers full range of light to medium duty working parts:

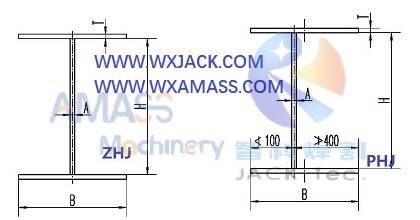

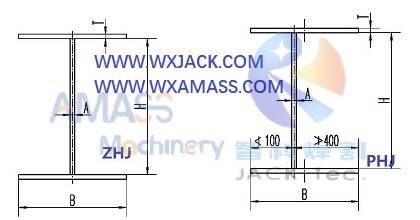

1) Cross section of H Beams available from Wuxi JACK H Beam Steel Structure Fabrication Machine: (Fig.1)

2) ZHJ series focuses on producing welding H Beam with equal length wings of flange;

3) PHJ series can produce welding H Beam with both equal and unequal length wings of flange;

4) Thickness: Web thickness ranges from 5mm to 32mm, and Flange thickness ranges from 6mm to 40mm;

3. Role of 3 in 1 H Beam Fabrication Machine for Producing Light to Medium Steel Structure:

1) The Best Choice: Which means, as can be found from the above sketch, in the field of producing light to medium duty H Beam, the H Beam Assembly Welding Straightening Integral Machine is the best solution;

2) The finished welding H Beam produced from Wuxi JACK H Beam Assembly Welding Straightening Integral Machine: (Fig.2)

3) This covers all factors in lean production: Quality/ Cost Effectiveness / Productivity / Investment on Steel Structure Fabrication Machine and Saving on workshop space;

4) Rapid Growth: This is reason that, why these years in Chinese and across the globe Steel Structure industry, over 50% applicating cases of traditional H Beam Production Line has been replaced by the 3 in 1 H Beam Assembly Weld Straighten Integral Machine, and this trend keeps being continued at present;

5) Put into use at customer facility: 2 sets of Wuxi JACK ZHJ8018 H Beam Steel Structure Fabrication Machine: (Fig.3)

B. Recommended Equipment for Welding Thick H Beam: SAW H Beam Welding Machine:

1. Welding Technology Adopted in 2 Main Types of H Beam Welding Machine:

1) Leg Size: Meanwhile, Chinese National Standard stipulates that, for flange (Wings) thickness equals to 32 ~ 40 mm, the corresponding leg size of welding seam should be at least 12mm;

2) Relationship: This implicates that, Leg size should be around (0.5 ~ 0.6) times that of the flange thickness;

2. Niche Field of 2 Main Types of H Beam Welding Machine:

1) Comparison: On this aspect, although the 3 in 1 Integral Function H Beam Welding Machine has capability of producing 12mm leg size welding seam, its appearance does not look as good as welding seam produced from conventional SAW (Submerged Arc Welding) H Beam Welding Machine;

2) Anyway, the welding position of 3 in 1 H Beam Assembly Weld Straighten Integral Machine is adopted withflat welding, (Fig.4)

3) While SAW H Beam Welding Machine is adopted with 45° fillet welding: (Fig.5)

3. Proper Solution on Producing Mixed Types of H Beam with Steel Structure H Beam Fabrication Machine:

1) In a practical business case negotiated between customer and Wuxi JACK, customer has 40% of workpieces have thick thickness, right above 25mm, up to 40mm;

2) Under such condition, we recommend 1 set of LHT T Frame SAW H Beam Welding Machine, as complement on the 3 in 1 H Beam Steel Structure Fabrication Machine, for producing light to medium H Beam;

3) Wuxi JACK LHT T Frame SAW H Beam Welding Machine fabricating H Beam: (Fig.6)

4) Strong Points: This model of LHT SAW H Beam Welding Machine can not only produce H Beam, but also BOX Beam. Considering the wide variety of customer products, it may greatly widen scope of available working parts.

C. Solution on Producing 12mm Leg Size with Wuxi JACK 3 in 1 H Beam Fabrication Machine:

1. Single Pass of Welding Seam with H Beam Assembly Welding Straightening Integral Machine:

1) When making H Beam with 12mm leg size, some customers weld the H Beam with one time pass;

2) This can be made with 3 in 1 H Beam Fabrication Machine, but need to slow down welding speed;

2. Multiple Passes of Welding Seam with SAW H Beam Welding Machine:

1) Some customers make welding on the H Beam with two times pass. And, majority of customers have only 1 set of the 3 in 1 H Beam Steel Structure Fabrication Machine;

2) Practice: So, they need to unload the welded the H Beam, transport the H Beam back to input conveyor of the 3 in 1 Steel Structure H Beam Fabrication Machine by means of traveling crane, and load the H Beam into the 3 in 1 H Beam Welding Machine again, and carry out welding the second time;

3) Anyway, under the condition of only 1 set of the 3 in 1 H Beam Fabrication Machine, in the process from T Beam to H Beam, this is the practice necessary on the 2nd time loading workpiece into the H Beam Assembly Welding Straightening Integral Machine;

4) The moment of loading T Beam into the Wuxi JACK 3 in 1 Steel Structure H Beam Fabrication Machine, for welding the 2nd piece of web into H Beam at customer site: (Fig.7)

3. Rule of Thumb on Choosing H Beam Assembly Weld Straighten Integral Machine:

1) So, Wuxi JACK recommends such thick workpieces only takes small percentage of total volume of 3 in 1 H Beam Steel Structure Fabrication Machine workpiece--- had better keep it within 10% ~ 20% of total volume;

2) This is just rule of thumb (Empirical date) based on our experience.

D. Straightening Capability in Wuxi JACK H Beam Assembly Weld Straighten Integral Machine:

1. The straightening capability of Wuxi JACK 3 in 1 Steel Structure H Beam Fabrication Machine is 2 times that of competitors:

2. Max. 40mm Q235/ 28mm Q345 of Wuxi JACK equipment, compared with Max. 20mm Q235 of other suppliers;

3. So, the Wuxi JACK H Beam Steel Structure Fabrication Machine can also be applied as 1 set of HYJ-800 H Beam Flange Straightening Machine.

E. Advantages of Wuxi JACK Integral Function H Beam Welding Machine:

This topic is introduced in detail, in web page “Quick Understanding on Steel Structure H Beam Fabrication Machine”.

F. Business Case Example on Wuxi JACK Steel Structure H Beam Fabrication Machine:

1. H Beam Assembly Welding Straightening Integral Machine can also be applied into a miniature production line:

2. 2 sets of the 3 in 1 H Beam Steel Structure Fabrication Machine, intermingled with hydraulic drive 90° Overturning Equipment in between: (Fig.8)